|

Research project on the development

of new tools for musical expression at the University College Ghent

School of Arts

|

|

<Rodo>

an automated and interactive set of bronze tines

Godfried-Willem RAES

2013 - 2017

|

<Rodo>

Rods clamped on one side and free to vibrate at the other side are the acoustical

base of quite many musical instruments and sound installations: reed organs,

mouth organs, bandoneon, music boxes with a comb, nail violin, toy piano, Fender-Rhodes

piano, Waterphones, Harry Bertoia's installations, African lamellophones, clock

gongs to name just a few. Two classes of instruments using this sound source

should be distinguished: instruments that only use the fundamental resonant

tone (reed organs, Fender-Rhodes, music boxes) and that are always considered

pitched instruments and at the other hand those that use the broad spectrum

of overtones these rods can generate, when tuned to very low fundamental resonant

frequencies (clocks, Waterphone, toy piano...). The fundamental resonant frequency

of these rods is inversely proportional to the square of the length of the rod:

With: f= frequency in

Hz, L= length of the rod, k=diameter of the rod, Q= modulus of elasticity, r=

density of the material. (Olson, p.76)

With: f= frequency in

Hz, L= length of the rod, k=diameter of the rod, Q= modulus of elasticity, r=

density of the material. (Olson, p.76)

The <Rodo> robot was designed to be either an extension or a generalization

of the toy piano robot <Toypi>. Just like in

the toy piano, the sounds all stem from massive rods clamped at one end in a

solid cast iron bar. We started the project, as the automation of the small

instrument was very successful and appeared to have many more sonic possibilities

than we grasped at the start. So we thought of rescaling the design such that

the range would extend much lower and the maximum sound level quite a bit higher.

At the same time, we aimed at making the instrument a lot more sturdy than the

toy instrument, that needed all too many repairs because the tines broke very

easily on very fast note-repetition rates. Also quite some new features were

added in this design: individual dampers, an e-drive mechanism and a set of

sensors to allow gesture interactive activation and playing modes.

We started off by doing experiments on different metals and alloys for the

tines: martensic stainless steel, hardened spring steel, brass, aluminum, phosfor-bronze,

aluminum-bronze. We even experimented with some non metals such as bamboo, glass,

carbon-fibre. Those experiments made us drop the nonmetals very fast as the

sound was too weak or the rods too fragile. Obviously the evaluation of sonic

quality has to remain a quite subjective issue, since there is no standard to

compare to as we are designing a new instrument. After all these experiments

were performed we decided to go for the aluminum-bronze alloy. These rods produce

a very rich tone, though not as brilliant and loud as spring steel rods. As

we couldn't get beryllium copper (after the properties, it ought to be the perfect

material here) nor phosphor bronze (CuSn8) ,we cannot judge on these promising

alloys. In the design of <Rodo> we took into account the possibility for

tuning and adaptation to different tuning systems. To allow this, set screws

are used to fix the vibrating length of the tone rods. This arrangement makes

it possible to exchange the rods for other sets, as long as the diameter is

8 mm. By default the tuning is chromatic, equal temperament. The electromagnetic

driver feature however, can work in different tuning systems, including just

intonation. Due to the high inharmonicity of vibrating bars clamped at one end,

it is perfectly possible to consider the instrument as 'non-pitched' in the

context of orchestra compositions conceived for our robots. In this respect,

the instrument would sound like a set of gongs.

The acoustics of rods clamped at one end, after the theory books (Rayleigh,V1,p.278;

Talukdar) allow us to predict the frequency of the overtones.

| f0 (fundamental) |

1 |

| f1 |

6.276 |

| f2 |

17.547 |

| f3 |

34.155 |

| f4 |

56.84 |

| f5 |

84.91 |

The literature on the subject doesn't give any values for higher overtones than

f5. Also, different authors do not seem to agree on the exact values of the factors.

The factors derived from theoretical calculus, generally simplify the problem

by neglecting the torsional forces occurring in vibrating rods, only considering

lateral vibration. So, these factors can only be used as guidelines and experiments

were necessary to obtain more exact results.

One would expect that the perceived pitch of a struck and clamped rod would

correspond to at least one of these overtones, however -at least for the rods

we selected- this is not the case. In the table below we give the measured frequencies

of a single bronze rod, 8 mm in diameter and cut to a length of 961 mm. (An

extra length of 20 mm serves for clamping and thus can be considered acoustically

dead). The perceived pitch of this bar was C#3 raised 20 cents (139.45 Hz),

yet this pitch was not found back under forced resonance conditions::

| |

measured |

calculated |

remarks |

| f0 |

5 Hz |

4.937 Hz |

=MM296, checked by comparison to a metronome set to MM150 |

| f1 |

30.86 Hz |

30.987 Hz |

almost unmeasurable |

| f2 |

86.19 Hz |

86,638 Hz |

|

| f3 |

168.64 Hz |

168.64 Hz |

reference tone used for best match with calculated spectrum |

| f4 |

280.47 Hz |

280.647 Hz |

this corresponds to the octave above the perceived pitch (139.45 Hz) |

| f5 |

416.00 Hz |

419.24 Hz |

|

| f6 |

581.66 Hz |

- |

|

| f7 |

773.50 Hz |

- |

|

| f8 |

986.80 Hz |

- |

|

| f9 |

1235.57 Hz |

- |

|

| f10 |

1807.5 Hz |

- |

|

| f11 |

2128.27 Hz |

- |

|

Measurements were performed under forced excitation using a transducer driven

by a Thurlby Thandar TG1006 DDS function generator with a 6 digit frequency

readout. Resonance's were determined by very slowly sweeping the sine wave frequency

and fine tuning to find the peeks in amplitude. When we tried to make the rod

resonate to the perceived pitch of 139.45 Hz, it clearly responded with the

pitch found in the table for f4. The conclusion is that our ear adds a 'missing

fundamental' here. This is not something novel, as similar phenomena have been

described with regard to the perceived pitches of tubular bells.

To conclude our measurements on the test rod, we tried to excite it with a

bow and could find all overtones from f2 to f9 back, be it sometimes after quite

some attempts as it seems difficult to predict the pitch one will get when bowing.

Starting from the measurements and experimental data obtained, we designed

a small computer program to calculate all 31 rods based on a perceived pitch

range from C3 (midi note 48) to F#5 (midi note 78) for equal temperament and

a basic tuning to A=440 Hz..

| midi

note |

frequency |

rod length |

id. with

clamp |

f0 |

note0 |

f1 |

note1 |

f2 |

note2 |

f3 |

note3 |

f4 |

note4 |

f5 |

note5 |

| 48 |

130.8 |

989.16 |

1009.2 |

4.603 |

-9.946 |

28.89 |

21.85 |

80.77 |

39.65 |

157.2 |

51.18 |

261.6 |

60 |

390.8 |

66.95 |

| 49 |

138.6 |

961 |

981 |

4.876 |

-8.946 |

30.6 |

22.85 |

85.57 |

40.65 |

166.6 |

52.18 |

277.2 |

61 |

414.1 |

67.95 |

| 50 |

146.8 |

933.64 |

953.64 |

5.166 |

-7.946 |

32.42 |

23.85 |

90.66 |

41.65 |

176.5 |

53.18 |

293.7 |

62 |

438.7 |

68.95 |

| 51 |

155.6 |

907.06 |

927.06 |

5.474 |

-6.946 |

34.35 |

24.85 |

96.05 |

42.65 |

187 |

54.18 |

311.1 |

63 |

464.8 |

69.95 |

| 52 |

164.8 |

881.24 |

901.24 |

5.799 |

-5.946 |

36.4 |

25.85 |

101.8 |

43.65 |

198.1 |

55.18 |

329.6 |

64 |

492.4 |

70.95 |

| 53 |

174.6 |

856.15 |

876.15 |

6.144 |

-4.946 |

38.56 |

26.85 |

107.8 |

44.65 |

209.8 |

56.18 |

349.2 |

65 |

521.7 |

71.95 |

| 54 |

185 |

831.78 |

851.78 |

6.509 |

-3.946 |

40.85 |

27.85 |

114.2 |

45.65 |

222.3 |

57.18 |

370 |

66 |

552.7 |

72.95 |

| 55 |

196 |

808.1 |

828.1 |

6.896 |

-2.946 |

43.28 |

28.85 |

121 |

46.65 |

235.5 |

58.18 |

392 |

67 |

585.6 |

73.95 |

| 56 |

207.6 |

785.1 |

805.1 |

7.306 |

-1.946 |

45.86 |

29.85 |

128.2 |

47.65 |

249.6 |

59.18 |

415.3 |

68 |

620.4 |

74.95 |

| 57 |

220 |

762.75 |

782.75 |

7.741 |

-0.946 |

48.58 |

30.85 |

135.8 |

48.65 |

264.4 |

60.18 |

440 |

69 |

657.3 |

75.95 |

| 58 |

233.1 |

741.03 |

761.03 |

8.201 |

0.054 |

51.47 |

31.85 |

143.9 |

49.65 |

280.1 |

61.18 |

466.2 |

70 |

696.4 |

76.95 |

| 59 |

246.9 |

719.94 |

739.94 |

8.689 |

1.054 |

54.53 |

32.85 |

152.5 |

50.65 |

296.8 |

62.18 |

493.9 |

71 |

737.8 |

77.95 |

| 60 |

261.6 |

699.44 |

719.44 |

9.206 |

2.054 |

57.77 |

33.85 |

161.5 |

51.65 |

314.4 |

63.18 |

523.2 |

72 |

781.6 |

78.95 |

| 61 |

277.2 |

679.53 |

699.53 |

9.753 |

3.054 |

61.21 |

34.85 |

171.1 |

52.65 |

333.1 |

64.18 |

554.4 |

73 |

828.1 |

79.95 |

| 62 |

293.7 |

660.18 |

680.18 |

10.33 |

4.054 |

64.85 |

35.85 |

181.3 |

53.65 |

352.9 |

65.18 |

587.3 |

74 |

877.4 |

80.95 |

| 63 |

311.1 |

641.39 |

661.39 |

10.95 |

5.054 |

68.71 |

36.85 |

192.1 |

54.65 |

373.9 |

66.18 |

622.2 |

75 |

929.5 |

81.95 |

| 64 |

329.6 |

623.13 |

643.13 |

11.6 |

6.054 |

72.79 |

37.85 |

203.5 |

55.65 |

396.1 |

67.18 |

659.2 |

76 |

984.8 |

82.95 |

| 65 |

349.2 |

605.39 |

625.39 |

12.29 |

7.054 |

77.12 |

38.85 |

215.6 |

56.65 |

419.7 |

68.18 |

698.4 |

77 |

1043 |

83.95 |

| 66 |

370 |

588.16 |

608.16 |

13.02 |

8.054 |

81.71 |

39.85 |

228.4 |

57.65 |

444.6 |

69.18 |

740 |

78 |

1105 |

84.95 |

| 67 |

392 |

571.41 |

591.41 |

13.79 |

9.054 |

86.56 |

40.85 |

242 |

58.65 |

471.1 |

70.18 |

784 |

79 |

1171 |

85.95 |

| 68 |

415.3 |

555.15 |

575.15 |

14.61 |

10.05 |

91.71 |

41.85 |

256.4 |

59.65 |

499.1 |

71.18 |

830.6 |

80 |

1241 |

86.95 |

| 69 |

440 |

539.34 |

559.34 |

15.48 |

11.05 |

97.16 |

42.85 |

271.7 |

60.65 |

528.8 |

72.18 |

880 |

81 |

1314 |

87.95 |

| 70 |

466.2 |

523.99 |

543.99 |

16.4 |

12.05 |

102.9 |

43.85 |

287.8 |

61.65 |

560.2 |

73.18 |

932.3 |

82 |

1393 |

88.95 |

| 71 |

493.9 |

509.07 |

529.07 |

17.38 |

13.05 |

109.1 |

44.85 |

304.9 |

62.65 |

593.5 |

74.18 |

987.8 |

83 |

1476 |

89.95 |

| 72 |

523.2 |

494.58 |

514.58 |

18.41 |

14.05 |

115.5 |

45.85 |

323.1 |

63.65 |

628.8 |

75.18 |

1046 |

84 |

1563 |

90.95 |

| 73 |

554.4 |

480.5 |

500.5 |

19.51 |

15.05 |

122.4 |

46.85 |

342.3 |

64.65 |

666.2 |

76.18 |

1109 |

85 |

1656 |

91.95 |

| 74 |

587.3 |

466.82 |

486.82 |

20.67 |

16.05 |

129.7 |

47.85 |

362.6 |

65.65 |

705.8 |

77.18 |

1175 |

86 |

1755 |

92.95 |

| 75 |

622.2 |

453.53 |

473.53 |

21.89 |

17.05 |

137.4 |

48.85 |

384.2 |

66.65 |

747.8 |

78.18 |

1244 |

87 |

1859 |

93.95 |

| 76 |

659.2 |

440.62 |

460.62 |

23.2 |

18.05 |

145.6 |

49.85 |

407 |

67.65 |

792.3 |

79.18 |

1318 |

88 |

1970 |

94.95 |

| 77 |

698.4 |

428.08 |

448.08 |

24.58 |

19.05 |

154.2 |

50.85 |

431.2 |

68.65 |

839.4 |

80.18 |

1397 |

89 |

2087 |

95.95 |

| 78 |

740 |

415.89 |

435.89 |

26.04 |

20.05 |

163.4 |

51.85 |

456.9 |

69.65 |

889.3 |

81.18 |

1480 |

90 |

2211 |

96.95 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The negative fractional midi note numbers in the note0 column (giving the fundamental

frequency of the rods) are colored brown, as these cannot be properly expressed

in MIDI. Beyond that, it will be clear that they are absolutely inaudible. To

measure their frequency, a calibrated stroboscope can be used. The notes given

as overtones are notated as fractional midi, the integer part being the midi

note and the fractional part the fraction in cents. Note that the (nearly) fifth

intervals between the notes 4 and 5 are the cause of our perception of a missing

fundamental, heard as f4 / 2.

To strike the tines, we decided to use Kuhnke thrust type solenoids with conical

face armatures. Type HM157 has an armature weighting only 8 g. The nominal voltage

for 100% duty cycle is 24 V, but at that voltage the attack time is 34 ms for

a traject of 5 mm. The data sheet specifies:

| duty cycle |

power |

attack time |

force |

voltage |

| 100% |

2.8 W |

34 ms |

1 N |

24 V |

| 70% |

4.3 W |

|

1.5 N |

30 V |

| 45% |

6.5 W |

|

2 N |

36 V |

| 25% |

10 W |

|

2.5 N |

45 V |

| 15% |

18 W |

|

3 N |

60 V |

| 5% |

52 W |

8 ms |

5 N |

103 V |

The DC resistance of the coil is 206 Ohms. We decided to design the robot for

operation on 60 V and thus the duty cycle should be restricted to 15%. Thus

the maximum note repetition speed at full power should be brought down from

the theoretical maximum of 50 strokes a second to ca. 15 strokes a second. Power

supply requirements can now be derived from these data: we have 31 solenoids

and thus the required power becomes: 18 W * 31 * 0.15 = 84 W. In order to stay

on the safe side, a 48 V ac transformer rated at 100 VA should do the job. After

rectification and smoothing, this will give us a dc voltage of ca. 65 V without

load, going down to 48 V al full load. By raising the voltage, we can improve

the attack time considerably as shown, but one should keep in mind that the

fall back time is limited by the force of gravity. When we calculate this for

a fall trajectory of 5 mm ( t = SQR(0.005/4.9) we get 32 ms. Thus the fastest

full up-down cycle would take 40 ms, leading to a fastest possible repetition

speed of 25 Hz. However, in practice when driven much faster than these repetition

speeds, it still works fine but the anchors will not fully fall back between

strokes. As a consequence, the amplitude of the produced sound will decrease.

The mass of the longest tine being ca. 400 g entails that the striking force

for a good excitation ought to be between 0.39 N and 0.78 N. These values will

be reached with midi velocity values around 80.

An extra and new feature of the <Rodo> design, as compared to <Toypi>

is the electromagnetic feedback driver mechanism. To this end we mounted a powerful

(100 W) electromagnet very close (leaving just an air gap less than 0.1 mm)

to and underneath the cast iron bar. This electromagnet is driven by a high

power digital driver whose input comes from a Microchip 24EP128MC202 microprocessor.

The input for the driver can be either a signal picked up with a piezo transducer

from the soundboard filtered and processed by the microcontroller, or an injected

drive signal under midi-controll. This mechanism enables bowed and sustained

sounds to be produced from this instrument. Rodo can sound very much like a

bowed string instrument in this mode, although sound build-up is rather slow

due to the inertia of the mass of the rod assembly.

An improvement over the <Toypi> robot certainly consists in the damping

possibilities offered here. Each rod has an individual damper mounted exactly

above the point of excitation. The duration of the contact between the felt

covered damper and the tone rod can be controlled with the release value of

the note-off command. A sustain controller (#64) is implemented, to disable

the damping functionality completely. A controller is used to set the default

damper-contact-time for note-off commands with release parameter 0. This was

done for user friendliness, as most commercial sequencers do not offer the user

the possibility to send note-off with release values, although these are part

of the standard midi specification.

For the damper mechanism, we went for tubular push type solenoids (Lucas-Ledex

type...). This entailed the use of return springs, calculated such that at rest

their force just keeps the damper and the plunger above the tone rods without

making contact. As the plungers on these tubular solenoids have an open cylindrical

head, we attached 10 mm brass disks to the ends and fitted the return spring

over the plunger. We used the same springs as we had custom made for our

player pianos. There is a slight problem with the damper mechanism: as the

anchors are free to move above the rods, mechanical resonances can occur at

high resonance peaks of the rods. This causes a rattling noise.

A special feature of the <Rodo> robot is that it can be used fully stand-alone

as a gesture controlled robot. To achieve this <Rodo> has two microwave

radar systems on board. These radars, operating in the X-band at 10.587GHz,

can measure and detect body movement up to a distance of 10 meters. The amount

of movement as well as the velocity and accelleration of the gestures can be

detected. The radar sensors as well as the associated microprocessors responsible

for the data analysis are mounted on the left and right sides of the robot.

If no external midi signal is connected, <Rodo> will allways operate as

a stand alone interactive robot. If an external midi signal is connected, the

operational parameters for the interactive mode can be changed.

The <Rodo> robot is available as a stand-alone interactive audio art

installation. As such it was presented in the SMAK museum in Ghent, september

2021. In 2024 it has undergone a major revision and improvement of the e-bow

mechanism.

Midi implementation and mapping:

Note off: steers the dampers on the rods, if sustain is switched off. Value

0, makes use the the default damper time set by controller #14. Value 127 keeps

the damper on as long as a note-on is not received. Values between 1 and 126,

control the time the damper felt stays in contact with the rod. Note that it

is possible to play a nice pp by using the dampers as very soft beaters. This

is done by sending only note-off commands with the release value set for the

required velocity in the range 1 to 126.

Note on: The velocity byte steers the force of the strokes. For very fast repetition

rates, low values for velocity should be used.

The lights are mapped on midi notes as follows: (left and right hereunder are

defined from the viewpoint of the listener)

- Note 112 and 113: Blue LED spotlights on the front. 112 is right, 113 is

left.

- Note 114 and 115: Yellow LED spotlights left and right on the bottom plate

in the back. 114 is right, 115 is left.

- Note 120 and 121: Red LED spotlights to the floor. 120 is left, 121 is right.

- Note 124 White LED strip on the beaters

- Note 125 White LED strip on the back side

- Note 126 Red rotating warning light

Key pressure: this command should be used to send precise pitches to the e-drive

mechanism independently from the operation of beaters and dampers. Polyphony

is not implemented here. The note range here is 48 to 97. The key pressure value

sets the attack level of the note. To switch the note off, the pressure value

should be set to zero. This will only work if controllers 3, 5 and 6 are switched

ON.

Controllers:

- #1: e-drive jitter (default 0, e-drive inject mode only)

- #2: waveform control (duty cycle) for e-drive inject mode only. Default

= 101

- #3: e-bow on/off switch . Default = 0, off.

- #4: e-bow feedback mode switch. Default = 0, off

- #5: e-bow note inject mode on/off switch. Default = 0, off

- #6: e-bow notes steered by note-on/off commands or by keypressure commands.

Default = 0: note on/off steers ebow.

- #7: e-drive amplitude sustain level for e-drive inject mode . Default value

= 64 [this was ctrl.#11 up to 2016, so if you have old files with tracks or

code for <Rodo>, you have to change this]

- #11: volume control for feedback mode. Controller #4 must be ON for this

to work. Default value = 0

- #14: default damper time (used when note-off + release is not used but only

note-on with velo=0). On cold boot or reset, this value is set to 40. The

range is 6ms to 747ms.

- #15: all dampers on/off. With value 0, all dampers

are released. With value 127, the dampers stay on until released by sending

value 0. Reception of new

note-on commands will release the dampers for those notes. This controller

is non-sticky, so it can be sent many times with the same value.

- #16: if set to 0, note-on commands will always release

the damper, regardless the value set for it with the release byte or by controller

#14. If set to any other value, it is possible to attack the rods with the

damper still on. By default this controller is off.

- #17: sets the attack time for the e-drive mechanism

in inject mode. Default value = 14

- #18: sets the decay time for the e-drive mechanism

in inject mode. Default value = 6

- #19: sets the release time for the e-drive mechanism

in inject mode. Default value = 10

- #64: Sustain on/off

- 0 or any value < 64 enables the dampers. Damping force is controller

either by the release byte of the note-off command, or by the value set

with controller #14

- 64:or any value > 63 disables the dampers, so sustain is active.

Sending this command, immediately releases all dampers.

- #65: Disable interactivity. When 0, the interactive mode of operation is

enabled. This is the default on start-up. When any value > 0 is sent, the

interactive mode is disabled.

- #66: Power on/off: This resets the controllers to the default cold boot

values, except for the interactive mode. Power off will always disable the

interactive mode.

- #70: set the time interval for the first derivative of speed, accelleration.

Only active in RADAR interactive mode. Default value = 32

- #71: set the time interval for the first derivative of amplitude. Only active

in RADAR interactive mode. Default value = 64

- #72: modulates the RADAR carrier frequency for the left RADAR (nr1) ( 3

MHz range). Default value = 0

- #73: modulates the RADAR carrier frequency for the right RADAR (nr2) (3

MHz range). Default value = 127

- #74: sets the noise level for the gesture analysis. Default value = 10

- #75: Changes the mapping for speed on pitch for the ebow in interactive

mode for both radars. The firmware will autoregulate this value starting from

the value set with this controller.

- #76: Changes the mapping for speed on pitch for the beaters in interactive

mode for Radar1. The firmware will autoregulate this value starting from the

value set with this controller.

- #77: Changes the mapping for speed on pitch for the

beaters in interactive mode for Radar 2. The firmware will autoregulate this

value starting from the value set with this controller.

- #78: Changes the mapping of movement accelleration

on note repetition speed in interactive mode for Radar 1

- #79: Changes the mapping of movement accelleration

on note repetition speed in interactive mode for Radar 2

- #123: All notes off. Releases all dampers and switches off the lights. It

does not reset any controllers.

Pitch bend: used for changing a frequency for the e-drive

mechanism. This will only work if controller #3 is set to a value > 0. The

range is a quartertone up or down. The command should be given before the note-on

command.

Program change: used to steer the tuning of the notes injected in the ebow.

- Value 0: standard equal temperament

- Value 12: Just intonation tuning based on C

- Value 13: Just intonation tuning based on C#

- Value 14: Just intonation tuning based on D

- Value 15: Just intonation tuning based on Eb

- Value 16: Just intonation tuning based on E

- Value 17: Just intonation tuning based on F

- Value 18: Just intonation tuning based on F#

- Value 19: Just intonation tuning based on G

- Value 20: Just intonation tuning based on G#

- Value 21: Just intonation tuning based on A

- Value 22: Just intonation tuning based on Bb

- Value 23: Just intonation tuning based on B

Key pressure: if controllers #3 , #5 and #6 are switched on, keypressure command

can be used to steer note playing with the e-bow independently from the beater

mechanism. The range implemented here is larger: 48 to 97. However, the implementation

is monophonic. A new note will always replace the playing note. Sending the

key pressure command with a zero value for pressure, switches the note off.

<Rodo> uses midi channel 7 (counting 0-15)

Technical specifications:

- sizes: 1200 mm x 1040 mm x 900 mm

- weight: 65 kg

- transportation: needs a small truck and wide enough access doors (>=

105 cm). No flightcase.

- power: 235 V / 220 VA

- Radar frequency used: 10.587 GHz (range: 10.5855 GHz to 10.5885 GHz)

- Radar range: <= 10 m , 180 degrees in the horizontal plane.

- tuning: A=440 Hz

- Loudness level: 20dBA to 86dBA

- Insurance value: 14.500 Euro

Design and construction: dr.Godfried-Willem

Raes (2013-2017/2024)

Collaborators on the construction of this robot:

- Mattias Parent, Moniek Darge, Laura Maes (requisites and mechanical help)

- Xavier Verhelst, Bastiaan Braadt (application research)

- Tim Deurinck (polystyrene research)

- Johannes Taelman & Kristof Lauwers (ARM board firmware for the e-drive

mechanism in version 1.0, 2014) The 2017 firmware was written by Godfried-Willem

Raes.

- Lara Van Wynsberghe, Emilie De Vlam (application research)

Music composed for <Rodo>:

- Godfried-Willem Raes: Namuda Study #44, "Rods for Rodo" (2014)

- Lara Van Wynsberghe: 'Kutstuk' (with <Aeio>) (2016) (written for Marijs

Boulogne and Emilie De Vlam).

- Godfried-Willem Raes: "RadaRodo" (2017), embedded interactive

composition.

- Kristof Lauwers: Study #23 for Rodo (2017) MIDI_FILE

, MP3 Recording

Construction Diary:

- 05.09.2008: Kuhnke solenoids ordered, anticipating the construction of a

completely new toy piano.

- 12.07.2012: Cast iron bar (40 x 40 x 1020) ordered from Demar-Lux to serve

as a holder for the tines.

- 12.07.2013: First practical sketches and drawings. Tone rod construction

principle and soundboard.

- 19.12.2013: Experiments with Maxon motors on tone rods and strings.

20.12.2013: Tone rod bronze delivered from Demar Lux. These rods are 8 mm

diameter and the alloy is Cu Al10 Ni5 Fe4 (Aluminium-bronze). Weight per meter

of length: 0.4 kg. Calculated density: 7.957 kg/l. (after the data sheet:

7.6 kg/l). Brinell hardness: 180. Tensile strength:640 N/mm2. 0.2% stretch

limit 270 N/mm2, stretch: 10%. This alloy contains 8.5 to 11% aluminum, 4

to 6% Nickel,, 2 to 5% Iron, and less than 1.5% Manganese, the remainder being

copper.

- 21.12.2013: Comparative tests on different materials and alloys. The bronze

rods were selected as the most 'musical' ones.

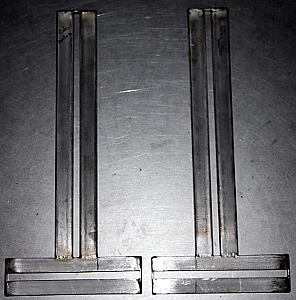

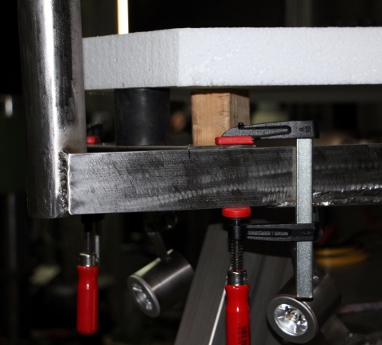

- 22.12.2013: Construction of the cast iron bar to hold the tone rods. This

bar is 1020 mm long, square section 40mm x 40mm. Weight: 12 kg. Alloy: GG25

(DIN 1691). There will be place for 31 rods if we stick to a distance between

rods of 30 mm. This is the construction drawing:

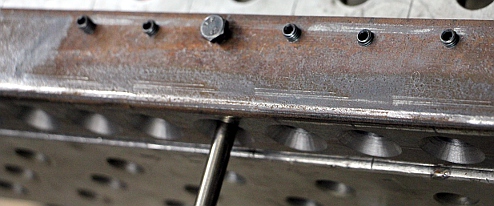

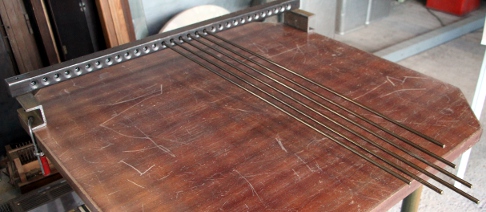

Here are some pictures taken during this construction session:

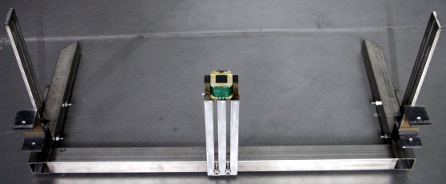

- 23.12.2013: Three test rods mounted and checked for produced pitch.

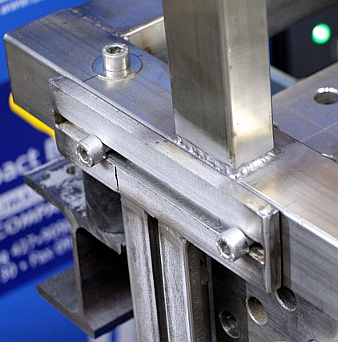

In the next picture the set screws for tuning adjustment are shown:

In the next picture the set screws for tuning adjustment are shown: Calculation

utility, based an acoustics theory books formulas programmed in Power Basic

Console Compiler. (Source code: rodo.bas). Kuhnke solenoids selected: type

HM157.F.24 VDC.100%ED. Extra bronze rods ordered from Demar-Lux. Hand reamer

8.0 mm purchased as well as a new set of M6 threading tools (hand taps).

Calculation

utility, based an acoustics theory books formulas programmed in Power Basic

Console Compiler. (Source code: rodo.bas). Kuhnke solenoids selected: type

HM157.F.24 VDC.100%ED. Extra bronze rods ordered from Demar-Lux. Hand reamer

8.0 mm purchased as well as a new set of M6 threading tools (hand taps).

- 24.12.2013: Calculation and design works. M6 x 16 set screws bought from

MEA. Work slowed down due to an emergency admission in the hospital: muscle

fraction or hernia attack.

- 25.12.2013: Precision measurement of resonance under forced excitation.

- 26.12.2013: Working out experimental results and comparison with theoretical

values. A program written to calculate all rod lengths such that we can start

sawing all rods to size.

- 27.12.2013: Total cost of the bronze tone rods will amount to 523 Euro.

The cost of this alloy amounts to 27.52 Euro a kg. Further drilling of the

5mm holes for clamping the rods. Threading to M6 for set screws. Surface grinding

to remove rusts and light polishing. All holes for the rods drilled to 7.9

mm and further honed to exactly 8.00 mm. First set of six tone rods cut to

size and tested for tuning.

- 28.12.2013: The total length of all rods together will be 21.597 m, so with

a mass of 0.4 kg/m the weight of all staves together will be 8,638 kg. Experiments

with different soundboard shapes and materials. Polystyrene works well if

clamped between the rod-holder and a strong piece of staff material. Wood

also sounds well, but we may have trouble finding a large enough soundboard.

Two end holes drilled

in the cast iron stave and provided with M12 threads for mounting the soundboard.

Start construction of the solenoid holding profile. This will be made from

a length of aluminum 50x30x3 L-profile. We did choose aluminum because its

better for dissipating the heath from the solenoids. The solenoids are mounted

with two M3x6 bolts each.

Two end holes drilled

in the cast iron stave and provided with M12 threads for mounting the soundboard.

Start construction of the solenoid holding profile. This will be made from

a length of aluminum 50x30x3 L-profile. We did choose aluminum because its

better for dissipating the heath from the solenoids. The solenoids are mounted

with two M3x6 bolts each.

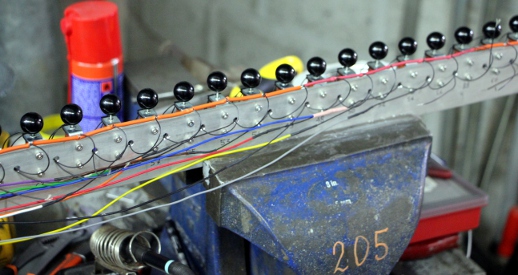

For the beaters

we plan to use M4 threaded Bakelite spheres. Inserts to fit the M2 threads

on the solenoid anchors to be constructed from M4x8 setscrews.

For the beaters

we plan to use M4 threaded Bakelite spheres. Inserts to fit the M2 threads

on the solenoid anchors to be constructed from M4x8 setscrews.

- 29.12.2013: Damn, Sunday... shops are closed. Continuing work on the solenoid

assembly. First attempt to prepare a beater: the 15 mm Bakelite balls have

an internal M4 thread, about 12 mm deep. So, we drill a 1.4 mm hole in a M4x10

setscrew on the lathe and after this we cut an M2 thread -by hand, in three

passes- in the hole. We will have to do this 31 times... First attempts very

unsuccessful.

- 30.12.2013: Considering the possibility to add a very strong electromagnet

just under the cast iron bar to allow the rods so sing. The input signal could

either come from the rods (in controlled feedback mode) or from an ARM processor

with properly adapted wave synthesis. Design of a damper bar to be placed

over the rods, driven by another set of solenoids. To 50 mm wide pieces cut

of from an HEA 100 profile to test usability as standoff's for the cast iron

bar. M4 x 8 setscrews bought from MEA, together with a new set of handtaps

M2. Threading these setscrews with M2 threads seems to become an endless,

if not impossible undertaking by hand. In a couple of hours, all our M2 taps

broke and we didn't even get a single bolt finished... At a cost of 30 Euro's

for a set of taps, this is becoming prohibitive. Looking for alternatives:

having this part of the job done in an automated factory, or drill 2 mm holes

and glue the anchors to the set screws with cyanoacrylate glue.

- 31.12.2013: Flatface grinder (Bernardo, Austria), ordered months ago, came

flowing in. Design of a possible driver circuit for the electromagnetic activation

of the cast iron bar. We will have to take the octaving problem into account!

We could use an Axo ARM board to do the signal processing, if Johannes Taelmans

firmware is capable enough for handling this. Version 1 of a welding plan

for the chassis and trolley worked out.

- 01.01.2014: Wheel base worked out. We will use spoke wheels again, as on

<Whisper>.

- 02.01.2014: Thread adapters M4-male to M2-female seem to exist! We ordered

them from Newport, type nr. TR-M2M4. They are expensive though: 360 Euro for

100 pieces.

Spoke wheels ordered from Kaiser+Kraft. (415 mm x 60 mm, 120 Euro each).

Spoke wheels ordered from Kaiser+Kraft. (415 mm x 60 mm, 120 Euro each).

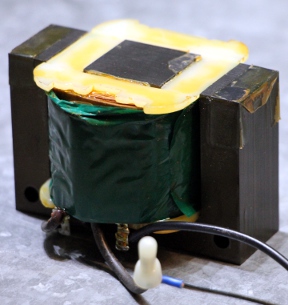

- 05.01.2014: What about using an old bulk eraser as an electromagnetic driver

for the cast iron bar? Digged one up dating from the seventies: Radio Shack,

100 W / 220 V bulk eraser, maximum on-time: 1 minute. Tried on Rodo and it

seems like it's going to work if we feed if with a high voltage signal. The

DC resistance of the coil was measured as 21.27 Ohm, the inductance as 312

mH at 1 kHz, raising to 325 mH at 100 Hz and 344 mH at 10 kHz.

The picture shows the electromagnet as found in the bulk eraser.

The picture shows the electromagnet as found in the bulk eraser.

- 06.01.2014: Design of the power amplifier module for driving the electromagnetic

exciter. The M4x6 setscrew, M2 taps and the vibration dampers ordered from

Fabory came in.

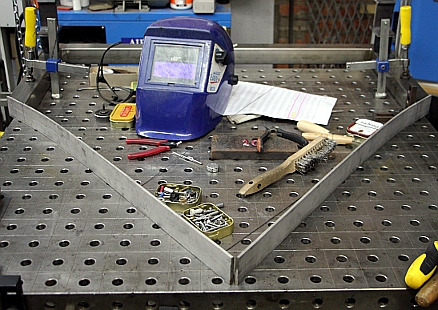

- 07.01.2014: Steel cutting and welding works on the under-chassis. Horizontal

structure uses stainless steel 50x50x2 profiles. Wheel holders: 50x30x3. Welding

plan further worked out.

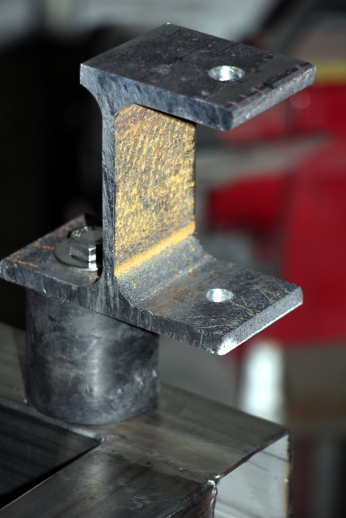

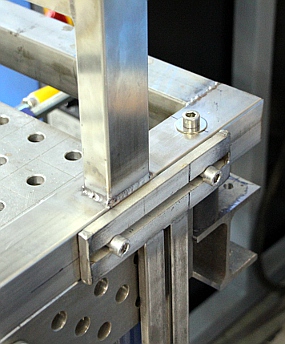

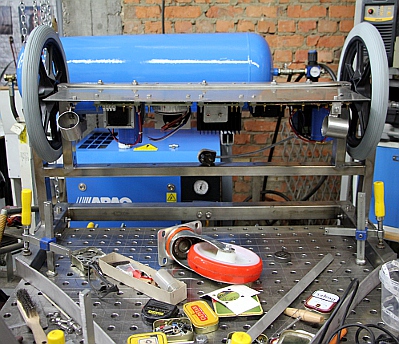

The pictures show

the assembly of the holders for the cast iron bar. The soundboard is not mounted

here, but will be fitted between the HEA100 profile and the rubber damper.

The pictures show

the assembly of the holders for the cast iron bar. The soundboard is not mounted

here, but will be fitted between the HEA100 profile and the rubber damper.

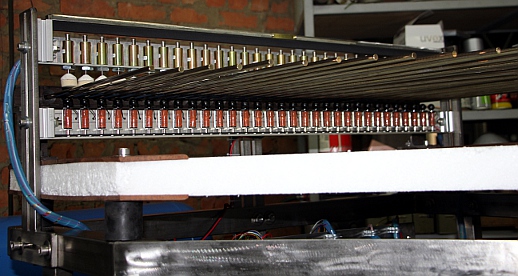

- 08.01.2014: Experiments with soundboard materials. Start construction of

the damper assembly, using Lucas Ledex tubular solenoids (push type), from

a length of aluminum 50 x 30 x 3 L profile (same as used for the beater assembly).

The holes for the solenoids are 14 mm and the threads on the solenoids are

M14 x 1.5. The distance between the holes is -as for the beaters- 30 mm. We

will have to provide a spring inside the solenoids with a strength such that

as rest the dampers to not make contact with the tone rods. We may have to

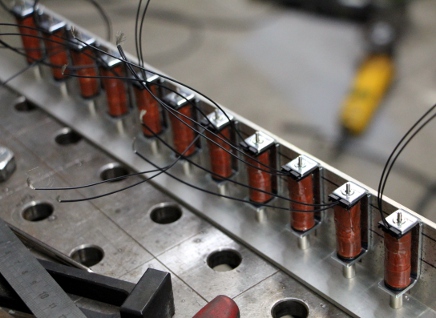

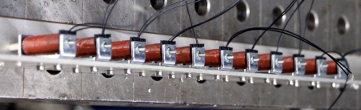

order these custom made from Veren Algoet. Here is the damper solenoid assembly

without the plungers and the damper heads:

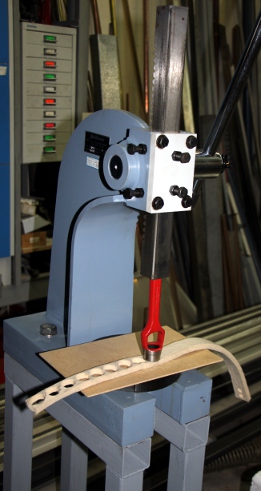

- 09.01.2014: Design of adjustable mounts for both the beater- and the damper

assembly. Adjustment should be possible both horizontally and vertically.

Horizontal range: 80 mm, vertical range 120 mm. Cutting of the 31 damper felts

(diameter 25 mm, 10 mm thick) using the arbor press and a dinking die.

These felt pads will be glued on 25 mm conical valves mounted upside down.

The centered 2 mm hole has to be slightly enlarged as the plungers have a

stem diameter of 2.35 mm.

These felt pads will be glued on 25 mm conical valves mounted upside down.

The centered 2 mm hole has to be slightly enlarged as the plungers have a

stem diameter of 2.35 mm.

- 10.01.2014: We cannot assemble and test the dampers as long as we did not

fit the return springs. The felt dampers have to be glued on the plungers

and then cannot be easily removed again. The ordered M4-M2 thread adapters

came in from Micro-Controle Spectra-Physics s.a.

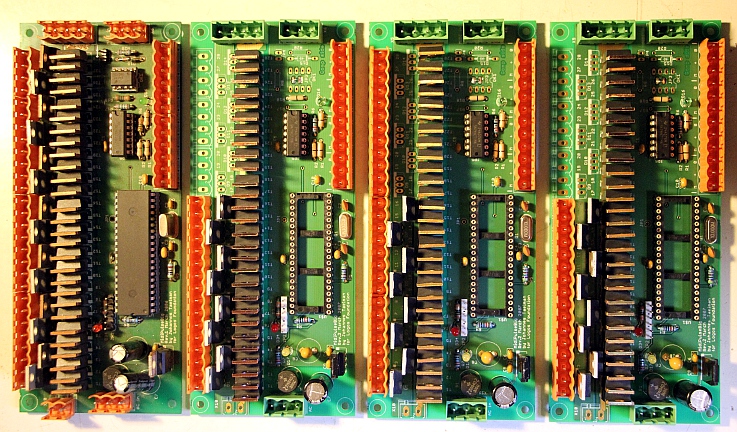

- 11.01.2014: Start coding for the beater PIC-controller boards. The source

code for these, under development, is at http://www.logosfoundation.org/instrum_gwr/rodo/picworks/Rodo_Beaters1.bas.

It must be compiled using the Proton Compiler in combination with MPLAB.

- 12.01.2014: First version of the firmware for the damper controller boards.

This can be found back at http://www.logosfoundation.org/instrum_gwr/rodo/picworks/Rodo_Dampers1.bas.

We still have to assemble the boards though. Support for <Rodo> added

in our GMT software, so we can perform the required testing. Construction

of the return springs and the brass discs to retain them on the plungers holding

the dampers. To make these brass discs, we used the arbor press with a 10

mm dinking die on 0.5 mm thick brass foil (sheet metal).

The brass discs were glued on the flat plunger end using Loctite 401 cyanoacrylate

glue. For the return springs we used the same type as we had custom made for

the player piano robots. Note that very much on purpose we dropped the springs

over the plungers whilst the glue had not fully set, thus they are also glued

to the plungers at their end.

The brass discs were glued on the flat plunger end using Loctite 401 cyanoacrylate

glue. For the return springs we used the same type as we had custom made for

the player piano robots. Note that very much on purpose we dropped the springs

over the plungers whilst the glue had not fully set, thus they are also glued

to the plungers at their end.  Since

the springs unavoidably tend to make the plungers, and thus with them the

dampers, bounce on release, we may have to add a felt covered debouncing bar

over the entire assembly. This is as yet to be experimentally found out. Gluing

of the 25 mm felt discs to the inverted conical valves, using Loctite 5920

copper silicon. We prepared the 2 mm holes in the conical valves by hammering

a spare plunger with the 2.35 mm shaft in them to a depth of 6 mm. This enlarges

the holes in the wood slightly and makes a tight fit later on. As the silicone

tends to creep slightly through the hole, we may have to use the arbor press

again to force the plungers into the felt holders.

Since

the springs unavoidably tend to make the plungers, and thus with them the

dampers, bounce on release, we may have to add a felt covered debouncing bar

over the entire assembly. This is as yet to be experimentally found out. Gluing

of the 25 mm felt discs to the inverted conical valves, using Loctite 5920

copper silicon. We prepared the 2 mm holes in the conical valves by hammering

a spare plunger with the 2.35 mm shaft in them to a depth of 6 mm. This enlarges

the holes in the wood slightly and makes a tight fit later on. As the silicone

tends to creep slightly through the hole, we may have to use the arbor press

again to force the plungers into the felt holders.

- 13.01.2014: Suitable transformer digged up for the damper power supply:

12V /25A. Firmware version 1.0 for beater-pic and damper-pic uploaded in two

chips and tested on our test-board with the GMT code. Functionally everything

seems to run fine. Controllers 14,15,16,64 tested under GMT. Note-off with

release runs fine as well. The scaling of course will depend on the behaviour

on the instrument itself. Firmware source code edited in order to program

the second beater and damper PIC's. In principle we have all four chips ready

for testing now. Soldering works on the midi-pulse boards started.

- 14.01.2014: Design work for the power supplies. As we want to avoid using

SMPS types (because of the trouble we had with them in the past with fast

switching solenoid loads and both EMC and emitted ultrasound) , we have to

come up with a very stable design capable of delivering at least 20 A. A bunch

of LT1084CP12 type 12 V/5 A regulators, operating in parallel may be a viable

solution. If we add power diodes and maybe a small resistor in series with

the output, we could even easily get at ca. 10 V, just a bit over the 9.4

V 100% duty cycle specification for the damper solenoids.

- 15.01.2014: Traced a factory that could cut out the required sound board

from polystyrene (Isomo, brand name for styrofoam).

- 16.01.2014: Technical drawing prepared. The voltage regulators 12 V/ 5 A

(LT1084CP12) came in from Farnell together with a fresh load of 18F4620 microprocessors.

Further design and calculations on the power supplies.

- 17.01.2014: Drawing a design for a PC board. If we want to place all (heavy

and large) components on the board, we need at least a 3 mm thick PC board.

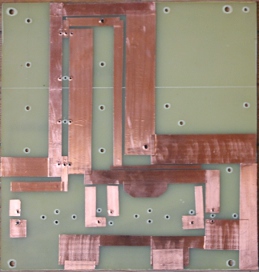

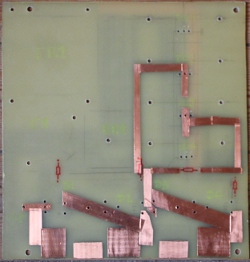

Taking into account the very high currents involved, we decided to hand-make

a double sided PC board using adhesive copper foil. It looks a bit primitive...

- 18.01.2014: Assembly of the experimental board for the 25`A / 12 V power

supply. Carefull tinning of the adhesive copper foil is essential as the adhesive

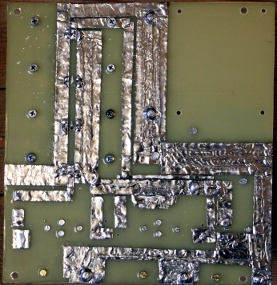

itself in non-conductive. This is the copper side after tinning:

We

got the entire power supply ready now. Testing also performed. Voltage over

the big capacitor measures 15 V. 12 V light supply measures 12.0 V, whereas

the outputs for the damper solenoids measure 11.8 V without load. Here is

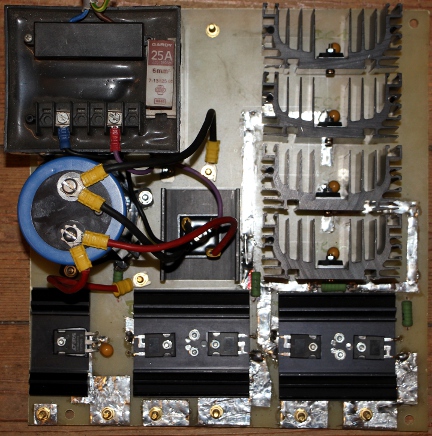

the finished module:

We

got the entire power supply ready now. Testing also performed. Voltage over

the big capacitor measures 15 V. 12 V light supply measures 12.0 V, whereas

the outputs for the damper solenoids measure 11.8 V without load. Here is

the finished module:  Sizes are 270 x 260 x 170 mm, or about twice as large as a comparable SMPS

power supply. The output terminals are formed from brass M4 bolts and nuts,

soldered on the copper side of the board.

Sizes are 270 x 260 x 170 mm, or about twice as large as a comparable SMPS

power supply. The output terminals are formed from brass M4 bolts and nuts,

soldered on the copper side of the board.

- 19.01.2014: Soldering works on the solenoid driver boards. 112 IRL640 Mosfets

in total on these boards alone...

Some

3500 solder joints to be done. Start work on the assembly of the 48/60V power

supply. Here also we use an epoxy carrier board.

Some

3500 solder joints to be done. Start work on the assembly of the 48/60V power

supply. Here also we use an epoxy carrier board.

- 20.01.2014: Further work on the 48/60V power supply. This carrier board

can also hold the transformer for the 5V logic power supply. The regulators

are on board of the pulse boards, so these just need a 6 V AC source. Sizes

are: 270 x 120 x 140 mm.

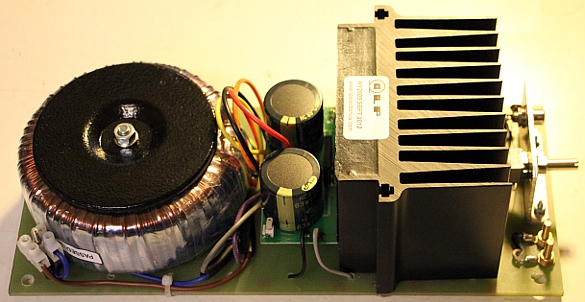

Start

construction of the carrier board for the ILP HY2005 power amp module and

its toroidal transformer. The link has to be soldered on the module, as required

for 8 Ohm operation. For good impedance matching, we will have to use a matching

transformer on the output. Maybe be could recycle an old vacuum-tube amplifier

output transformer. We should still have a few 100 W vacuum tube amplifiers

around... Maximum output voltage from the ILP amp is 31 Vrms, so a 1:10 voltage

ratio transformer should do the job.

Start

construction of the carrier board for the ILP HY2005 power amp module and

its toroidal transformer. The link has to be soldered on the module, as required

for 8 Ohm operation. For good impedance matching, we will have to use a matching

transformer on the output. Maybe be could recycle an old vacuum-tube amplifier

output transformer. We should still have a few 100 W vacuum tube amplifiers

around... Maximum output voltage from the ILP amp is 31 Vrms, so a 1:10 voltage

ratio transformer should do the job.

- 21.01.2014: Finishing the power amplifier module. This sizes 270 x 120 x

90 mm.

It's not large

enough to also fit the required impedance matching transformer. For this we

could also try a toroidal 2 x 35V to 230V rated for 160 W. It might be a good

idea to fit the bulk eraser coil with a temperature sensor that could be read

by the ARM board processor, such that a burn-out protection would be implemented.

It's not large

enough to also fit the required impedance matching transformer. For this we

could also try a toroidal 2 x 35V to 230V rated for 160 W. It might be a good

idea to fit the bulk eraser coil with a temperature sensor that could be read

by the ARM board processor, such that a burn-out protection would be implemented.

- 22.01.2014: Instead of providing a temperature sensor on the bulk eraser,

we decided to simply equip it with a temperature switch on the windings, such

that the circuit breaks if ever the coil gets too hot. Looking at the design

now, it seems a bit stupid to use the impedance transformer. Instead we would

have done much better by rewinding the coil on the coil former of the bulk

eraser assembly to give it an inherent 8 Ohm impedance... But, obviously,

coil winding by hand is always a pretty tedious job. Block terminal contacts

ordered from Farnell. Styrofoam boards (4 pieces, as we expect accidents to

happen...) ordered to use as soundboard. Redesign of the stainless steel structure.

Suffering from a hernia, we have to postpone the cutting and welding works

a bit it seems.

- 23.01.2014: Very gentle -because of the hernia- TIG welding works on the

wheel base for the back wheels. Stainless steel profiles used: 50 x 30 x 2.

Start working on

the adjustable holders for the beater and damper mechanisms. The are to be

made from 10 mm thick staff material.

Start working on

the adjustable holders for the beater and damper mechanisms. The are to be

made from 10 mm thick staff material.

- 24.01.2014: Holders with slides for M8 and M10 bolts finished. Cutting,

welding, grinding. One for the left side, one for the right side. The vertical

slide made from 25 x 10 staff material, the horizontal one from 20 x 10 material

such that the total height is exactly 50 mm.

- 25.01.2014: Holes drilled in chassis and slides mounted and tested.

Construction

of the slide for mounting the electromagnetic driver. Three bars of 20 x 10

x 300 stainless steel, welded together with two 10 mm gaps. The core of the

driver is only 24 mm wide, so we need a pair of spacers to adjust it such

as to strike in the middle of the 40 mm wide cast iron bar. The spacer ought

to be 8 mm and can be welded on the slide.

Construction

of the slide for mounting the electromagnetic driver. Three bars of 20 x 10

x 300 stainless steel, welded together with two 10 mm gaps. The core of the

driver is only 24 mm wide, so we need a pair of spacers to adjust it such

as to strike in the middle of the 40 mm wide cast iron bar. The spacer ought

to be 8 mm and can be welded on the slide.  Mounting

holes for the solenoid are 5 mm. Bolts for the slide must be M10 x 70 or M10

x 80. Possible front wheel mechanism found in the hardware store. Hoping to

dig up a suitable wheel now from our collection...

Mounting

holes for the solenoid are 5 mm. Bolts for the slide must be M10 x 70 or M10

x 80. Possible front wheel mechanism found in the hardware store. Hoping to

dig up a suitable wheel now from our collection...

- 26.01.2014: Finalizing the e-drive mechanism. Start construction of the

bend sides of the main chassis. These sides are made from two pieces of 50

x 5 x 820 stainless steel. Bending by hand in a large vise clamp. Welded on

the back chassis on the welding table.

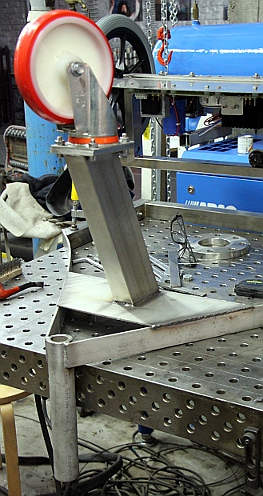

.

Further works on the front wheel design. Building height of the wheel will

be 240 mm. The mounting plate measures 110 x 140 mm.

.

Further works on the front wheel design. Building height of the wheel will

be 240 mm. The mounting plate measures 110 x 140 mm.

- 27.01.2014: Still waiting for the spoke wheels, the brass rods and the styrofoam

soundboard... Panel voltmeter (moving coil) with range 300V ac added for monitoring

the e-drive output. (Type YH670, class 2.5) Mounted on an small aluminum subpanel

on the board housing the impedance transformer. Holes drilled for he circuitry

holding panels to be cut out from 2 mm thick stainless steel plates. So, we

decided not to weld these on, but rather to make them removable for ease of

maintenance and final assembly. Instrument under construction explained to

a small group of students.

- 28.01.2014: Cutting and bending of the mounting plate for the power supplies,

mains switch, I/O connectors etc. Cut from 2 mm thick stainless steel, left

over from the construction of the Logos building. The wheels came in, unfortunately

they came with spindle holes 20 mm in size instead of the 12 mm we had already

drilled in the chassis... Holes drilled for mounting of the supply components,

for the MIDI I/O connectors, the mains entry, mains power switch and a switch

for mode of operation selection (autonomous robot / midi controlled automaton).

- 29.01.2014: Mounting of the connectors on the bottom plate. Test mount of

the bottom plate assembly. We need 6 mm hole mounting studs in PTFE or Epramid.

The styrofoam sound boards still did not come in!

- 30.01.2014: Bending of the back wheel structure to bring it perfectly in

shape after welding deformations. Construction of the 20 mm shafts for the

back wheels.

- 03.02.2014: The stock of bronze rods came in from Demar-Lux. Still no styrofoam

boards though...

- 05.02.2014: M12 threads made in the wheel shafts. The wheels can be mounted

now. Cutting of the tone rods from bronze staff material... trouble though:

the composition is different than that of our test staves. Either we have

to re-order the staves, or recalculate the staves for the new alloy.

- 06-17.02.2014: Research on sensor systems and information retrieval to be

used for the robotic components in <Rodo> but also for the gesture recognition

coding under GMT.

- 18.02.2014: Test mounting of the power supply carrying plate on the lower

wheel chassis. The M10 mounting bolts will have to welded op the base plate.

Test mount of the power supply assemblies on M6 MF threaded vibration dampers.

Cutting of the two holders for the 12V LED spotlights underneath (50mm diameter

stainless steel tube, length 50mm).

- 21.02.2014: Distance holders turned on the lathe from epramid staff material.

Vibration dampers would after all have been overkill here. M10 bolts welded

on the power supply assembly.

- 22.02.2014: Spotlight holders constructed for mounting on the power supply

plate. These are adjustable.

- 23.02.2014: Assembly of the back wheels, the wheelbase and mounting on the

horizontal skeleton. Welding on the horizontal structure.

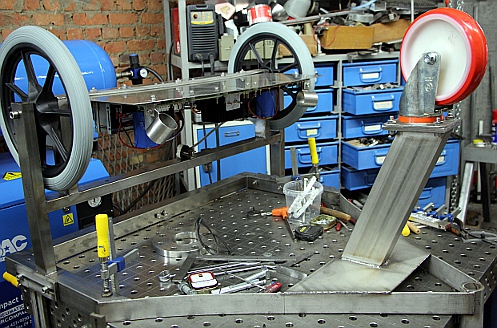

Start

construction of the front wheel structure. Still very handicapped by a hernia...

Start

construction of the front wheel structure. Still very handicapped by a hernia...

- 24.02.2014: Construction of the front wheel. Welding works. Wheel mounting

plate: 160 x 100 x 10, with four 10mm holes. Vertically inclined pole: 100

x 50 x 2 profile. Mounting plate welded on chassis, cut out from 3mm stainless

steel plate.

- 25.02.2014: Drawing and plasma cutting of the carrier plate for the microcontrollers

and the robotic components. Construction of two light holders for the front

next to the frontal wheel. First tests with styrofoam soundboard.

- 26.02.2014: Drilling and honing of all mounting holes on the microcontroller

plate. The plate can be taken out by loosening the five M10x50 and two M10

x 25 bolts. Construction of the mounting plate (vertical) for the four PIC

processor boards. This assembly mounts on the backside of the horizontal plate

with two M12 bolts.

With the help of Sebastian, Mattias and Kristof, we managed to flip the entire

construction and bring it back in position on the welding table...

With the help of Sebastian, Mattias and Kristof, we managed to flip the entire

construction and bring it back in position on the welding table...

Two blue LED spotlites

mounted in their holders on the front and two yellow LED spotlites in the

holders on the power supply plate.

Two blue LED spotlites

mounted in their holders on the front and two yellow LED spotlites in the

holders on the power supply plate.

- 27.02.2014: Instruction to the instrument building students at the conservatory

about the ongoing <Rodo> project. Tools and techniques explained. Wiring

of the on/off switch and the midi-input connections. We will leave the drilling

of the mounting holes for the robotic components for later on, as we do not

now the sizing of these components yet.

- 28.02.2014: Start wiring of the power supply lines.

- 01.03.2014: Continued wiring of the PIC processor boards. Mounting and wiring

done (except the dampers and the solenoids) such that we can test the board

and the initial coding in the firmware. Yellow LED spotlites mapped on notes

114 and 115 and controlled by the Dampers-1 microcontroller board. At first

boot, with all voltages applied, everything seems to run fine.

- 03.03.2014: Tracing a suitable transformer for the required +24V voltages

for the LED strips and the sonar sensor. An old transformer block from a HP

inkjet printer may do the job. Rodo project demonstration for Brent Wetters.

- 04.03.2014: Design of the dual +24V power supply.

- 05.03.2014: Dual + 24V power supply soldered and tested. HP transformerblock

mounted on the power supply chassis plate. This was done using two strap ties

and some parabond under the transformer housing. Wiring of the e-drive module.

We mount the components for the 24V supply on this same subchassis module.

The 24V power supply has two separate outputs and uses a Weidmueller connector.

- 06.03.2014: All ground connections made. Alu-bronze bars delivered. Bronze

cutting with the students.

- 07.03.2014: Front lights wired. Test mount of the mechanism. Cutting and

first tuning of the bronze staves.

Two out of the eight rods in the new delivery appeared to be cast from a different

alloy again, so we had to re-cut them. A lesson learned: never trust batches

of delivered alloys to be identical...

Two out of the eight rods in the new delivery appeared to be cast from a different

alloy again, so we had to re-cut them. A lesson learned: never trust batches

of delivered alloys to be identical...

- 08.03.2014: Support for the front of the styrofoam soundboard designed and

constructed.

Bakelite

beaters loosely screwed on the beater anchors. The wite stuff underneath the

beaters on the picture is the styrofoam soundboard.

Bakelite

beaters loosely screwed on the beater anchors. The wite stuff underneath the

beaters on the picture is the styrofoam soundboard.  Start wiring of the solenoids. Wiring just the beater solenoids took us a

full day and still we have to do the Weidmueller connectors. Wire colors follow

resistor color coding, staring with note 48 being black. The common positive

voltage is the thick red wire. A white LED strip (24V) is mounted on the userside

of the beater assembly. These LED strips require 240mA current (4.5W), so

we should be carefull not to exceed the limits of the 24V power supply if

we are adding more of these lights...

Start wiring of the solenoids. Wiring just the beater solenoids took us a

full day and still we have to do the Weidmueller connectors. Wire colors follow

resistor color coding, staring with note 48 being black. The common positive

voltage is the thick red wire. A white LED strip (24V) is mounted on the userside

of the beater assembly. These LED strips require 240mA current (4.5W), so

we should be carefull not to exceed the limits of the 24V power supply if

we are adding more of these lights...

- 09.03.2014: Wiring of the beater Weidmueller connectors: two boards. If

we mounted the tone rods, rodo could play already... Electrical tests o.k.

Design of a strong red LED light assembly for the underside. This uses 1W

LED's in SMD technology. Styrofoam soundboard cut to shape with a razor blade.

Frontal holder for the soundboard welded on.

- 10.03.2014: First test mount of the rod assembly on the styrofoam soundboard:

deceptive results, as the styrofoam is clearly not strong enough to hold the

weight and the pressure of the rod assembly. We could try to increase the

contact surface, for instance by mounting the rod assembly via a piece of

wood on the soundboard. On the underside, a larger surface is required as

well. So, we did cut out four pieces of wood and indeed, now it works fine

and with good resonance. In the definitive version we should remake these

pieces of wood from real good quality hardwood 10 mm thick and 50 mm wide.

(Meranti) As an alternative we could also try out titanium here.

- 11.03.2014: In need of long bolts M12, M10 and M8... up to MEA. Four support

plates sawn out from long aged tropical hardwood, thickness 8 mm. Now the

sound is o.k. It may be better not to support the front of the styrofoam,

as supporting it gives some damping of the lower frequencies.

First tests of the electromagnetic drive mechanism, using a tone generator

leading to a large smoke stack... Something is fundamentally wrong here...

Almost certainly we exceeded the 500mV max. input level.... Analysis of the

board revealed that the elco's exploded. 4.7mF/63V types, presumably with

an MTBF below 3000 hours. We will try to replace them with decent quality

100V types and hope the amp has survived it.

First tests of the electromagnetic drive mechanism, using a tone generator

leading to a large smoke stack... Something is fundamentally wrong here...

Almost certainly we exceeded the 500mV max. input level.... Analysis of the

board revealed that the elco's exploded. 4.7mF/63V types, presumably with

an MTBF below 3000 hours. We will try to replace them with decent quality

100V types and hope the amp has survived it.

- 12.03.2014: Apparently, not the elco's exploded, but the HY2005 module itself.

Bad luck... and high costs. As the HY2005 is no longer in production at ILP,

we will have to replace it with the ILP HY2004 type and adding a power supply

externally. Mattias Parent helps us out adjusting the Bakelite beaters for

a trajectory of 5.5mm to the tines. <Rodo> produces its very first tones

and scales under computer control! Apparently we forgot to implement the blue

LED spotlights on the front in de firmware for damper PIC1. Firmware revised,

not yet in the chip. GMT test-code adapted to make measurement of good velocity

scalings for the beaters possible. Our tests in this matter lead us to new

analysis of solenoid behaviour under fast repetition conditions. If the time

between two pulses becomes smaller than the fallback time of the anchor and

its load, the anchor will assume a 'floating' position without coming down.

As the pulse time is increased, the distance to the struck object becomes

smaller, repetition time can be increased but sound volume will go down. If

you go beyond the duty cycle limits, obviously the solenoid will burn out.

This confirms our observation that for very fast repetition rates, very low

velocity values have to be used.

- 13.03.2014: Working session with the instrument building students at the

Conservatory. Acoustic theory of styrofoam explained and demonstrated. Introduction

in welding technology. Firmware version 1.2 uploaded for beater PIC2, with

'dead-time' after strike provisions and new velocity scalings.

- 14.03.2014: Continued work on the damper assembly. All solenoids wired:

a full working day.... Weidmueller connectors to be done.

- 15.03.2014: Mounting of the damper felts on the solenoid anchors.

Wiring

of the Weidmueller connectors. The boards are up and running now. Further

work on the firmware is required.

Wiring

of the Weidmueller connectors. The boards are up and running now. Further

work on the firmware is required.

- 16.03.2014: Bounce-back bar over the damper assembly mounted.

This

bar carries also the engraved brass nameplate 'me fecit logos'. Firmware development

for the damper controllers. Midi implementation updated. The time the dampers

stay in contact with the tines can be controlled within the range 6 ms to

767 ms. Either the note-off release value or controller #14 can be used to

control this. Lights 116,117,118,119 implemented on the second damperboard,

although we have as yet no lights connected there. Rodo plays well now and

can be given in the hands of users/composers for evaluation. All controllers

implemented sofar tested with the coding in GMT.

This

bar carries also the engraved brass nameplate 'me fecit logos'. Firmware development

for the damper controllers. Midi implementation updated. The time the dampers

stay in contact with the tines can be controlled within the range 6 ms to

767 ms. Either the note-off release value or controller #14 can be used to

control this. Lights 116,117,118,119 implemented on the second damperboard,

although we have as yet no lights connected there. Rodo plays well now and

can be given in the hands of users/composers for evaluation. All controllers

implemented sofar tested with the coding in GMT. The left blue light appeared to be broken. Probably because of the strong

electromagnetic fields welding works caued too close to the LED... LED spotlite

replaced.

The left blue light appeared to be broken. Probably because of the strong

electromagnetic fields welding works caued too close to the LED... LED spotlite

replaced.

- 17.03.2014: Meeting with Kristof Lauwers on the way we are going to implement

the electromagnetic drive mechanism. The power amp (HY2004) has been replaced

and works fine now. We have to keep an eye on input and output conditions

though. Never ever exceed 500mV on the input! The frequency range should be

limited to 20Hz - 260Hz range. In the lowest range, resonances with the dampers

do occur.

- 18.03-21.03.2014: Kristof Lauwers at work on the development of the code

and patches for the ARM board, Axo project.

- 21.03.2014: Two red LED lights mounted on the underside. These need a 18

Ohm series resistor to work on 12 V DC. Each of these LED clusters draws ca.

200mA. Here is the datasheet.

- 22.03.2014: Finalisation of the wiring for the red lights. These are mapped

on midi notes 120 and 121, controlled by the PIC for the second set of beaters.

Power comes from the +12V lights power supply.

- 23.03.2014: Continued tests and evaluations on the e-drive mechanism. GMT

test-code further improved.

- 25.03.2014: Work session with the Axo firmware as developed by Kristof Lauwers.

- 26.03.2014: Axo board problems: input attenuator unavailable, variable midi

channel not implemented, strange behavior with output volumes. To be discussed

with Johannes Taelman. It seems the audio inputs on the board are very high

sensitivity and do not have an attenuator...

- 27.03.2014: Wiring of the Honeywell 944-T4V-2D-1C1-130E distance sensor

connector. The connector is Hirschmann type ELKA 5012 PG7, 5 pole , order

nr.933 170-100. The responsiveness of the distance sensor appears to be very

slow. Here is a link to the sensors manual.

- 28.03.2014: Distance data is refreshed only once every 1.2 seconds using

this Honeywell sensor.

- 31.03 - 03.04. 2014: Continued work on the ARM firmware by Kristof Lauwers.

- 03.04.2014: <Rodo> lifted from the welding table as we needed it to

be free for the construction of the <Snar2> robot. Now set up in the

center of the tetrahedron...

- 06.04.2014: The first interactive piece for <Rodo> is in the making:

Namuda Study #44.

First rehearsal with Dominica Eyckmans.

- 07.04.2014: Further debugging of the ARM coding.

- 08.04.2014: There must be a small bug in the PIC firmware for the beaters.

It doesn't seem to work under running status conditions. The dampers behave

correctly here...

- 09.04.2014: Bug found in the beater firmware. Repaired and both chips reprogrammed

with version 1.3

- 10.04.2014: Adding rotating red warning light, 24V. Mapped on midi note

126 and controlled by beater PIC 1.

- 11.04.2014: Television shooting session with Rodo for VRT 1.

- 12.04.2014: Attempts to power the ARM board from the general +5V V DC supply

such that is does no longer require the USB connection. Code tested for playing

Rodo with the dampers alone. This is the circuit:

- 13.04.2014: Rehearsal session with Dominica Eyckmans:

Rods for Rodo, namuda study #44.

- 14.04.2014: Stand-alone operation of the ARM/Axo board succesfull. The connectors

to the board are a bit shaky however. Start design of a PC board for the analog

input channels and sensing components.

- 16.04.2014: <Rodo> plays for the first time in public.

- 16.07.2014: Impedance transformer board soldered and mounted for the piezo-disks.

1:10 audio transformers used. This way there is no more risk for overloading

the ARM-AXO board input.

- 11.02.2016: Failure of the e-bow mechanism. Apparently the power amp is

dead. Maybe we should redesign this, for instance by using a Visaton exciter

instead of the electromagnet. This would greatly simplify the circuitry. However

we first have to find out what it sounds like. Drivers already ordered from

Reichelt.

- 14.02.2016: Repairing the original circuit, with an added diode compressor:

HY2004 amplifier module replaced. Measurements: with 160V ac on the output

transformer and over the driven electromagnet, the HY2004 gets pretty hot.

The amp output is delivering 23.5V to the transformer then, so it ought to

be well within specs... (66V pp output, that is).

HY2004 amplifier module replaced. Measurements: with 160V ac on the output

transformer and over the driven electromagnet, the HY2004 gets pretty hot.

The amp output is delivering 23.5V to the transformer then, so it ought to

be well within specs... (66V pp output, that is).

- 16.02.2016: HY2004 burned out again, despite the input protection, in the

music for our 'Oorsprong' production... Alternative approach seems required.

- 18.02.2016: 'Oorsprong' production done by using an external Maranz amplifier

replacing the HY2004. This is a temporary fix though.

- 14.03.2017: Redesigning the e-drive mechanism, using a dsPIC instead of

the ARM driving an IGBT in high frequency PWM mode. This is a pure digital

approach.

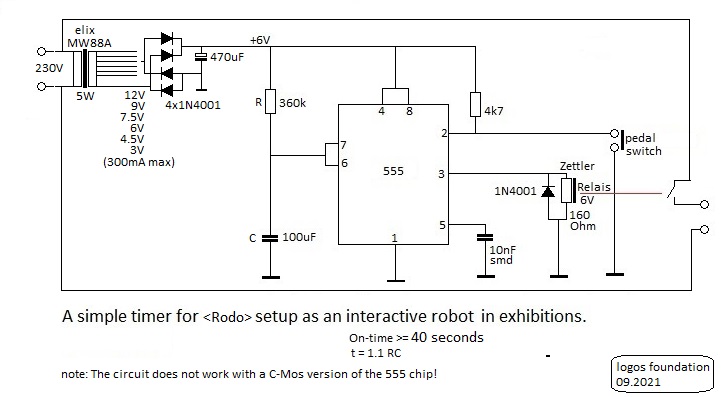

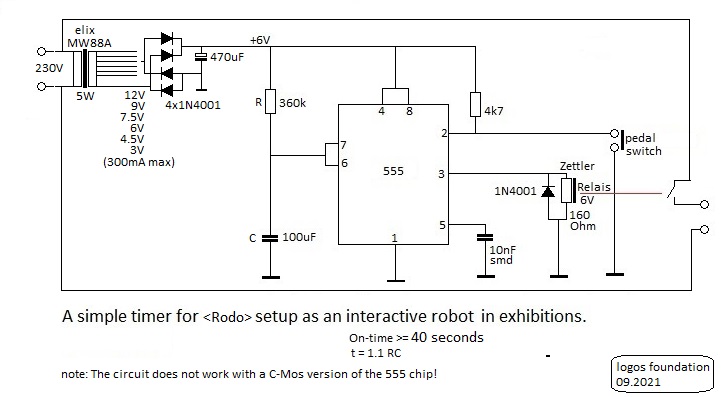

- 15.03.2017: Here is the new circuit:

Start of the design of an appropriate PCB. A very large heatsink is an absolute

requirement here. ARM board firmware for the sensor components (Axo platform)

by Kristof Lauwers and Johannes Taelman will no longer be needed, as we will

remove the Axo board.

Start of the design of an appropriate PCB. A very large heatsink is an absolute

requirement here. ARM board firmware for the sensor components (Axo platform)

by Kristof Lauwers and Johannes Taelman will no longer be needed, as we will

remove the Axo board.

- 16.03.2017: As we explained in full in our article on 'Expression Control

in Musical Automatons', the e-drive mechanism -not having a permanent magnet-

operates as a frequency doubler. Hence the unipolar rectification of the input

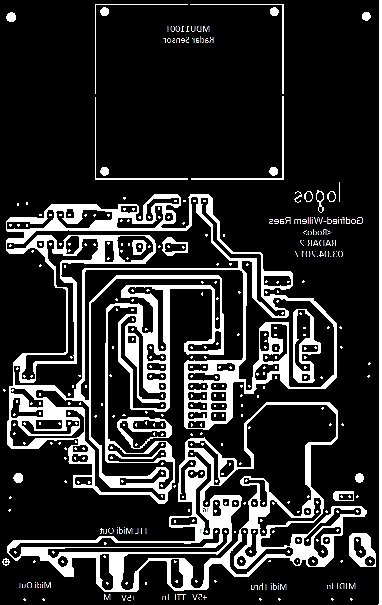

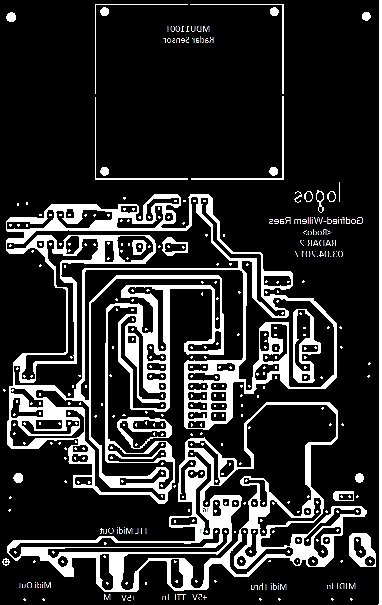

signal. Here is the design for the PCB (scaled at 200%):

- 17.03.2017: New PCB soldered. Start coding the new firmware and trying to

stick as much as possible to the original implementation.

- 18.03.2017: First tests revealed a bug in the hardware logic: the 7400 quad

nand gates is a mistake. We can solve the problem by replacing the chip with

a 74HCT30 8-input NAND-gate and pulling unused inputs up. PCB design modified

for future productions using all available pwm outputs from the microprocessor

chip. Midi implementation changed. Further work on the PIC 24EP firmware.

The ADC subsystem works now, but there are problems with the preamp. We configured

the ADC to work in 12 bit mode, so with an input range up to 3.3V this means

the resolution is 0.8mV. The preamp has a gain of 220k / 4k7 = 46, thus the

input signal should be limited to <= 0.072V and the resolution becomes

17uV, so near to the noise level to be expected. Is there a mistake in this

reasoning? Should we sync the sampling rate with the PWM base frequency? Should

we OR the values of PDC1 and PDC2?

- 19.03.2017: Indeed, there was a silly mistake in the opamp input circuit:

Uo = (U+ - U-) Av ,for U+=0 could only give negative voltages on the output

but as we use a unipolar supply this is impossible and thus the output will

be zero at all times... We should have used the non-inverting configuration.

As to the firmware: operating conditions are PTPER = 4096 (12-bit resolution

on the PWM) and PWM base frequency = n. Sampling_Rate . 4096, where n = 1,2,3,...

Still many troubles in getting the ADC to work properly.

- 20.03.2017: Mapping the ADC output on PDC2 might be a conceptual mistake,

as it would require the PWM base frequency to be set to >=20MHz (4096 ^2)

, clearly way above what's possible on the PIC. So, we changed the firmware

such that the ADC values steer timer4 pulsewidths. The timing resolution required

now becomes 59.5ns, still pretty extreme for the PIC as it entails a PWM frequency

of 16.7MHz.

- 21.03.2017: Finally got the ADC system to work properly in 12 bits and with

4096S/s. Now we can mount he IGBT and do the tests under load conditions...

We raised the sampling rate to 16384 S/s, as the 4kHz carrier was too strongly

found in the output in feedback mode. This also works now. Trying again to

steer PWM2 with the ADC. Now we got this working quite well. ILP-amplifier

and power supply removed from the Rodo assembly.

- 22.03.2017: Further work on the modifications of the hardware. Separation

transformer mounted. This transformer is technically not required, but was

added only for safety reasons. We keep the AC voltmeter. However it's still

too cold in the lodge for this kind of work and we have no money anymore to

heat it a bit... PCB design improved, for future projects along similar lines.

Here is a picture of the final board:

- 23.03.2017: Further wiring of the modules on the Rodo chassis.

- 24.03.2017: Start designing the hardware for the gesture sensing system

to be build into this robot.

- 25.03.2017: Design of a PCB for the radar gesture recognition hardware.

Finalising rewiring of all Rodo electronic modules. First testing of the e-drive

circuit: everything fine in the first 10 minutes, then de 1N5371 zener diode

over the driver coil went in smokes to heaven. We have to redesign this part

of the circuit. Should we use a VDR as spike protector or use an RC protection?

The IGBT itself gets barely warm, so that seems to be o.k. The moving coil

AC-voltmeter gives erroneous readings. Likely it does not work well under

high frequency circumstances. The air-gap between the cast iron bar and the

coil has to be enlarged.

- 26.03.2017: E-drive board repaired: de MUR diode exploded and also killed

the 60V zener diode. As a result, ithe IGBT got short circuited and also went

to heaven. As the IGBT c-e junctions were found welded together, the separation

transformer got an overload and its primary got shorted. Result the house

fuse got activated and we found ourselves in the dark. A quite expensive chain

reaction. We replaced the EREA transformer and modified the circuit to work

on 170V. We modified the damper circuit and inserted a BY228 diode in series

with a wirewound 82 Ohm power resistor. Of course we also replaced the IGBT.

It now works again, - the AC voltmeter now works again- but even with the

volume controller halfway, the 47uF electrolytic capacitor gets very hot.

We do not trust it in any case. Looking for a very low ESR type. Studying

the textbooks on MOV's or VDR revealed that they would not be a solution to

our problem here. Maybe we should have a fuse in the primary of the safety

transformer (0,8A, slow). This looks like a better circuit for feeding the

e-drive solenoid:

Yet to be tested.

Yet to be tested.

- 27.03.2017: The circuit with a BY227 in series with a 82 Ohm resistor not

only drives the 47uF cap very hot, but at high volumes and duty cycles the

resistor gets yellow hot... The IGBT barely gets warm, so we can have it dissipate