|

Microtonal Musical Robot |

|

<Cornalto>

a robotic Eb alto saxhorn designed and made to the order of Alain Van Zeveren dr.Godfried-Willem RAES 2021 |

|

Microtonal Musical Robot |

|

<Cornalto>

a robotic Eb alto saxhorn designed and made to the order of Alain Van Zeveren dr.Godfried-Willem RAES 2021 |

Robot: <Cornalto>

When starting the design and construction of this musical robot, we could build

further on the experiences gained through the realization of quite some automated

brass instruments build since 1999: <So>, a sousaphone, <Korn>,

a cornet, <Heli>, a helicon, <Bono>, a valve trombone and <Horny>,

a French horn, <Bug>, a fluegelhorn, <Hunt>, a hunting horn, and

<Trumpeter>, the latter also made on request for Alain Van Zeveren. Musically

speaking the cornet, the flugelhorn as all saxhorns are very similar instruments,

differing only in the range and the timbre they produce. They all have a conical

bore and are said to sound more mellow than the trumpet, the trombone and other

brass instruments with a cylindrical bore. The ambitus of the alto saxhorn (in

Britain often called a tenor horn) however is considered to be quite a bit more

limited, the lowest notes being never used. The textbooks mention 2 1/2 octaves

at the most. The alto is in fact not really a horn, although called altohorn

('althoorn' in Dutch), but a saxhorn like the tuba. Before the second world

war, the alto was often constructed in the shape of a horn (circular). Later

on its shape became prevalent as that of the tuba, the baritone and euphonium.

This picture shows both appearances of the same instrument:

Thus it made sense to start the design of this robot by examining the <Trumpeter> robot and improving over this one where ever possible. Again we used a membrane compressor directly coupled to the saxhorn via a capillary. In this case we could not use the original mouthpiece that came with the instrument as it didn't have a large enough cylindrical part that we could make to fit the throat of the membrane compressor. Thus we had to turn a new one on the lathe. The internal sizing conforms to the original mouthpiece and is just a little smaller sized in the capillary section. The motor driver causes resonance in the saxhorn tubing, but in this case there is no unidirectional windflow through the instrument. Instead, the wind flows over and back inside the bore. When a note is requested from the horn, the firmware will calculate the optimum valve combination -including non orthodox fingerings- for the requested pitch. Thus a resonant standing wave in the instrument can be produced. Microtonal pitches are implemented such that the instrument is capable of performing quartertone music, as well as a wide range of different tunings and temperaments with great perfection. The relatively low Q-factor of the horn (compared to strings...) as an acoustic resonator renders this very well possible. The signal generated in the compressormotor can be choosen by the users from a list of implemented models. All driving signals consist of two phases: an attack portion, derived from an excitation wave modeling the start of vibration on the lips and in the mouth cavity followed by a sustain phase wherein the waveshapes generated are based on different models of granular synthesis. At the one hand we have some waveforms shaped after a physical model of the air pressure waveform in the mouth cavity of a player. (Beauchamp, 1975,1980) and at the other we used calculated excitation waves derived mathematically from samples obtained by playing the actual instrument in different registers. (Raes, 2020). Since there is no loop coupling from the resonator to the generator, the sound generation mechanism is a hybrid somewhere between synthetic/electronic and natural/acoustic. The advantage being that the reliability of the robot becomes very high, but this is obtained a bit at the detriment of realism, in particular with regard to the onset of the sounds. The sound onset in this robot however, using the two phase approach, is already a major improvement over previous robots such as <trumpeter> and all earlier robotic wind instruments we designed. A dynamic formant filter was added using analogue electronic circuitry, in this case a pair of germanium diodes in series with a resonant LC circuit Thus the sound color will be, to a certain extend, a nonlinear function of loudness, conform to acoustic reality in brass instruments.

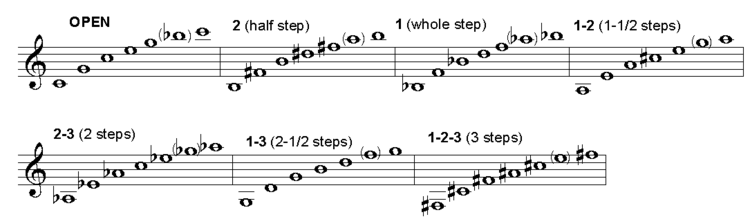

The valves are used in this instrument to tune the fundamental frequency of

the instrument. The valves can be controlled independently from the mouth driver

frequency. They are mechanically driven by large unipolar push solenoids (Banggood

types made in China, to save on cost) and use the (weakened) return springs

provided in the pistons, the return springs on the solenoids were removed. Furthermore

we mounted the saxhorn upside down such that gravity also helps improving fingering

speed. The notes that are normally produced using different valve combination,

following theory are:  Note that this is untransposed, so in reality everything will sound a minor

thirth higher on an Eb instrument. However, we found out that using the valve

combinations entailed by this system, does not always lead to optimum resonance

in the instrument. Thus we used the optimal valve combinations based on empirical

acoustic measurement. A deficiency we encountered in our <Korn> robot

was that the buildup of a sound pressure wave in the instrument was anticipating

the valve movement. The valves take about 10 ms to take position, thus here

we delayed the driver signal with the same amount in all cases where changes

of fingering are involved. This introduces some latency but makes the sound

quite a bit more realistic, in particular for the attack portion of the envelope.

This idea was first implemented and fully tested on the <Bug> robot. It

is also implemented in our <Trumpeter> robot and now also in this one.

Note that this is untransposed, so in reality everything will sound a minor

thirth higher on an Eb instrument. However, we found out that using the valve

combinations entailed by this system, does not always lead to optimum resonance

in the instrument. Thus we used the optimal valve combinations based on empirical

acoustic measurement. A deficiency we encountered in our <Korn> robot

was that the buildup of a sound pressure wave in the instrument was anticipating

the valve movement. The valves take about 10 ms to take position, thus here

we delayed the driver signal with the same amount in all cases where changes

of fingering are involved. This introduces some latency but makes the sound

quite a bit more realistic, in particular for the attack portion of the envelope.

This idea was first implemented and fully tested on the <Bug> robot. It

is also implemented in our <Trumpeter> robot and now also in this one.

As we had to save as much as possible on cost, we dropped all movement from the design. Thus the construction was a lot less involved than that of our moving brass robots <Bug>, <Korn>, <Horny> and <Hunt>.

The electronic circuitry -in overview- consists of only two 'intelligent' PC-boards:

Overview:

1. Midi-hub board: This board, using a Microchip 18F2620 controller, takes

care of the Midi I/O handling and communication as well as the control of the

three valves. The circuit for the pulse/hold function here follows a recipe

we applied nearly one hundredth times by now:  The PCB board, is a new design used for the first time for the <Trumpeter>

robot. It can in principle be applied for just about any brass instrument with

up to four valves to be automated.

The PCB board, is a new design used for the first time for the <Trumpeter>

robot. It can in principle be applied for just about any brass instrument with

up to four valves to be automated.

The source code for this processor is here.

The hex-dump for programming the PIC processor using MPLAB IPE is here.

2. Sound generator board: This board steers the 75 Watt motor compressor horn driver via a digital audio amplifier module. A 16-bit processor is used to generate the required waveform and two analog multipliers are used for envelope shaping and amplitude modulation. Thus we could maintain audio resolution even at the lowest soundlevels. Handling this in the full digital domain would have required a fast 32-bit processor. The analog dynamic formant filter also found a place on this board.

The power amp is a pure analogue design, using a high quality but by now obsolete

LM12 power opamp (introduced by National Semiconductor in 1988), in a 5-pin

modified TO3 package, rated for 150 Watt:  We

designed it back in 1991 (in fact to be used as a powerful ac source for tape-recorder

motors), but copies of it were used also for robots such as <Autosax>,

<So>, <Hunt> and <Trumpeter>.

We

designed it back in 1991 (in fact to be used as a powerful ac source for tape-recorder

motors), but copies of it were used also for robots such as <Autosax>,

<So>, <Hunt> and <Trumpeter>.

The source code for this microprocessor is here. Note that the code has to be compiles two times: once with the metacompiler constant $pitch defined, once with the $ampli constant defined.

The Hex-dump for the pitch processor is here, and the hex dump for the amplitude processor here.

A note on the compression driver:

see what we wrote on that topic on the <Trumpeter> page.

Power supply voltages and currents:

Midi Mapping and implementation:

Midi channel: 13 (fixed in the firmware)

Midi note range: 45 to 89. (Optimum sound in the range 54-82) Note on, velocity

is implemented and steers the level of the sustain phase in the adsr. We did

not implemented the acoustic pedal notes 33 to 39 as they are extremely difficult

to sound and lead to minimal resonance in the instrument. Thus the implemented

range is now continuous starting from note 45.

Note Off commands are required, but can be dropped for pure legato playing. Note off with release is implemented and can steer the release phase of the envelope. Note Off commands for notes that were not sounding are disregarded.

The red eye-lights are mapped on note 121 (cf.. Controller 69 below) and the tungsten 'nose'-light on note 120.

Controllers:

Controller 1: Noisiness of the sound [default = 48]

Controller 2: Vibrato delay time [default=64]

Controller 3: FM modulation depth (vibrato depth). Large values can cause audible artifacts, due to the modulation of the sampling frequency.[default=8]

Controller 4: FM modulation speed. (vibrato speed) [default=94]

Controller 5: AM modulation depth (tremolo depth) [default = 4]

Controller 6: AM modulation speed (tremolo speed) [default = 20]

Controller 7: used as a general volume controller. Note that timbre will change

as the volume is changed. On high settings, the formant frequency becomes more

dominant. [default = 90

Controller 13: allows changes of valve fingering during sounding notes. Bit 0 corresponds to the 1/2 tone valve, bit 1 to the 1 tone valves, and bit 2 to the 3 semitone valve. Using this controller it is also possible to change the fingering for a sounding note whilst it is sounding, thus rendering some sound coloration possible without changing the actual pitch.

The table below gives all details:

Ctrl 13 Value -1/2t (valve 2) -1t (valve 1) -1 1/2t (valve 3) 0 off off off 1 on off off 2 off on off 3 on on off 4 off off on 5 on off on 6 off on on 7 on on on

Controller 15: ADSR-period. [default = 24]

Controller 16: used to control the duration of the attack phase in the ADSR

cycle. [default = 32]

Velocity byte = attack level

Controller 17: sustain level [default = 74]

Controller 18 is used to control the duration of the decay after the attack,

the time required to reach the sustain level of the sound. [default = 32]

Controller 19 steers the duration of the release decay (from sustain level to

zero) starting after reception of a note off command. Release will be canceled

or interrupted with a new note on command if such a command comes within this

time. [default = 80]

The interdependencies of these controllers together with the velo byte is shown in the graph below:

CoController 20 - tuning for the alto horn . By

default equal temperament and A = 440 Hz for value 64. Acceptable values for

this controller are limited to:

Controller 25: Steers the attack force for the valve solenoids. [default =

88]

Controller 26: This controller steers the time the valves stay in their position

after reception of a note-off command. This implements some resonance in the

instrument after the excitation from the mouthpiece has stopped. It also avoids

unnecessary mechanical noise from the valves, in particular on repeated notes

or notes that can be produced with the same valve combination. [default = 32]

Controller 33: Selects different lookup tables for the fingerings. The default value 0 corresponds to our own findings in terms of optimal resonance. This lookup table differs quite a bit from the theory-book fingerings used for an Eb instrument. Controller value 3 corresponds to the official fingering for a high Eb alto horn. By setting this parameter to 9, the robot would use a lookup table as if it were an A-horn. With value 12, it would finger for a C-instrument . Note that we do not treat the instrument as a transposing instrument! Acceptable value for this controller are limited to the range 0 to 12. On cold boot, this controller is always set to 3, the standard value for an Eb instrument. This is not always the best choice!

Controller 41:Selects the waveform used for the low register, notes 45 to

69. The default setting here is 5. Range 1 to 12. Alternatives are 8, 7, 6,

1, 3

Controller 42: Selects the waveform used for the medium register, notes 70 to

83 . The default setting is 6. Good alternatives are 5, 8, 2 , 4, 3 or 11. Range

1 to 12.

Controller 43: Selects the waveform used for the high register, notes 84 to

87. The default setting is 3. Good alternatives are 1, 4 ,5, 9. Range 1 to 12.

Waveforms implemented for these three controllers:

| 0 | Attack wave, excitation wave | used as a first phase for all waveforms further implemented. Not selectable. |

| 1 | Wave_1, excitation wave | |

| 2 | Square Wave | 1 parameter: CC104, default setting is 42 |

| 3 | Wave_3, excitation wave | good for high notes |

| 4 | Wave_4, excitation wave | can be used for the medium register |

| 5 | Wave_5, excitation wave, derived from Eb (midi note 51) | excitation wave, acoustically corrected |

| 6 | Wave_6, excitation wave | excitation wave, some filtering applied |

| 7 | Wave_7, excitation wave | recorded with 1/2t valve depressed, a bit more rough |

| 8 | Wave_8, excitation wave | the mathematically correct excitation wave |

| 9 | Dirty Sine |

2 parameters: CC105, CC106 default setting for the parameters: 20 and 64 with CC105 = 64 and CC106 = 0, a pure sinewave is obtained. |

| 10 | Wave_10, output wave | recorded without valves depressed, not very useable. For development. |

| 11 | Beauchamp textbook, acoustical modeling, parametric |

4 parameters: CC100, 101, 102,103 the default settings are respectively 27,83,96,110 |

| 12 | Wave_12, excitation wave |

Controller 66: Power on/off switch (0 = off, any other value is on). Power off

also resets all controllers to their default startup values. Also resets the

wave tables to the default startup settings.

Controller 69: Switches automation for the red eye-lights on or off. If this

controller is reset, the eye-lights can be controlled with note on/off commands

for note 121.

Controller 80: Dynamic range mapping. The default is 62, resulting in a 30dB

dynamic range.

| value | mapping |

| 0-30 | 20dB |

| 31-62 | 30dB |

| 63-94 | 40dB |

| 95-126 | 50dB |

| 127 | 60dB |

Note that increasing the value of controller 80 and thus the dynamic range does not make the sound volume at its maximum any higher! The dB mapping steers the dynamic range, starting from the absolute maximum. So, if set to 64, corresponding to 40dB, the loudest and the softest volume levels will relate to each other as 100. Or, dynamic value 1 will be at -40dB compared to the maximum value 127. Here the maximum value is defined as 0dB. Note that changing this controller affects all amplitude related parameters, including the ADSR and the tremolo.

Controllers 100, 101, 102, 103: parameters for waveshape

parametric Beauchamp. . This applies to Wave11. It is mandatory that Ctrl100

< Ctrl101 < Ctrl102 < Ctrl103. After reception of controller 103, the

wave table will be recalculated. Following graph describes the waveform and

its parameters:  Note

that with some settings of parameters, this waveform may sound the wrong octave.

Note

that with some settings of parameters, this waveform may sound the wrong octave.

Controller 104: parameter for setting the symmetry when waveform 2 is selected. Value 64 makes a symmetric square. Valid values are between 1 and 126.

Controller 105: parameter for setting the symmetry when Waveform has been set to 9 (dirty asymmetric sine wave) .Value 64 makes a symmetric sinewave. Valid values are between 1 and 126. The graph illustrates the parameter:

Controller 106: parameter to set the level of noisiness in the waveform 9.

Controller 123: switches the sounding note off.

Pitch bend: The <Cornalto> robot can be used in any tuning system. In the drawing below we give the coding example for a quartertone scale:

Most good

sequencer software (such as Cakewalk or Sonar) uses the signed 14 bit format.

Note that one unit of the msb corresponds exactly to a 0.78 cent interval. To

convert fractional midi to the msb only pitchbend to apply follow following

procedure: if the fractional part is <= 0.5 then msb= 63 + (FRAC(note) *

128), if the fractional part is larger than 0.5, we should switch on the note

+ 1 and lower the pitch with msb= (1-FRAC(note)) * 128.

Note off does reset the pitch bend for the playing note! The resolution implemented

on <Cornalto> for pitch bend (and vibrato) is limited to 1/10th of a semitone.

Most good

sequencer software (such as Cakewalk or Sonar) uses the signed 14 bit format.

Note that one unit of the msb corresponds exactly to a 0.78 cent interval. To

convert fractional midi to the msb only pitchbend to apply follow following

procedure: if the fractional part is <= 0.5 then msb= 63 + (FRAC(note) *

128), if the fractional part is larger than 0.5, we should switch on the note

+ 1 and lower the pitch with msb= (1-FRAC(note)) * 128.

Note off does reset the pitch bend for the playing note! The resolution implemented

on <Cornalto> for pitch bend (and vibrato) is limited to 1/10th of a semitone.

<Cornalto> was finished in the month October of 2021.

Godfried-Willem Raes

Note: The valves of this instrument need valve oil to operate smoothly and in silence. However, do not apply any oil to the solenoids!.

Technical specifications:

Design, research and construction: dr.Godfried-Willem Raes (2021)

Collaborators on the construction of this robot:

Music composed for <Cornalto>:

Alain Van Zeveren, in the works...

Some pictures:

| Back to Main Logos page:index.html | To Godfried-Willem Raes personal homepage... | To Instrument catalogue |  |

Construction & Research Diary:

Both

instruments on this picture are the same instrument. Both are Eb instruments

and have the same range. The shape of the left side instrument was common

up to WW2, after that, they mostly took the shape of the tuba as shown on

the right side in the picture. Soundwise, the instrument doesn't sound like

an instrument of the horn family properly speaking. Although it's conical,

it is much less conical than the 'French' horn. PCB-films sent to Polo such

that we can start construction.

Both

instruments on this picture are the same instrument. Both are Eb instruments

and have the same range. The shape of the left side instrument was common

up to WW2, after that, they mostly took the shape of the tuba as shown on

the right side in the picture. Soundwise, the instrument doesn't sound like

an instrument of the horn family properly speaking. Although it's conical,

it is much less conical than the 'French' horn. PCB-films sent to Polo such

that we can start construction.

To do:

| (Terug) naar logos-projekten: | Terug naar Logos' index-pagina: | Naar Godfried-Willem Raes personal homepage... | Naar katalogus instrumenten |  |

Last update: 2023-03-26 by Godfried-Willem Raes

The following information is not intended for the general public, but is essential for maintenance and servicing of the robot.

Technical drawings, specs and data sheets:

Compression driver unit: Omnitronic, Model ED-100T, power rating 100W rms, impedance 16 Ohms. (Made in Germany (?)). Mouth opening: 1". Weight: 3 kg. The acoustic load does influence the measured impedance at 1kHz over a 1:2 range: with the mouth completely closed it measures 32.8 Ohms and with the mouth completely opened but without any resonator, 15.35 Ohms. This phenomenon does not occur for the very low neither for the very high frequencies. The frequency response is 350Hz to 5kHz. Sensitivity is 108dB for 1W at 1m, with horn mounted. The thread for mounting is 1 3/8"-18 TPI. (ca. 35mm) URL: http://www.omnitronic.com

Valve lookup tables (according to acoustic theory)

Power supply:

Circuit drawing for the valve control and MIDI hub board:

Firmware for the hub board:

PCB for this hub board designed for 3 or 4-valve brass instruments:

[scale 200%]

Soldered board:

Power supply modules for this board:

Compressor driver board (monophonic synth with acoustical modeling)::

Circuit drawing:

PCB for this circuit:  [scale:

200%]. An improved PCB for later versions is available. The placement of the

formant filter components was subject to improvements.

[scale:

200%]. An improved PCB for later versions is available. The placement of the

formant filter components was subject to improvements.

Current drawn by this board 310mA @ 5V supply.

Soldered board:

References:

Beauchamp, J.W. "Analysis and Synthesis of Cornet Tones Using Nonlinear Interharmonic Relationships". In: j-aes, volume 23, number 10, pages 778--795, 1975.

Beauchamp, J.W., "Analysis of Simultaneous Mouthpiece and Output Waveforms of Wind Instruments" . In: j-aes, 1980, Preprint No. 1626,

Benade, Arthur .H., "Fundamentals of Musical Acoustics". Ed.: Oxford University Press, 1976.

Fletcher, N.H. & Tarnopolsky, A. "Blowing pressure power and spectrum in trumpet playing" In: J. Acoust. Soc. Am., volume 105, number 2, part 1, 1999.

Martin, Daniel W., "Lip vibrations in a Cornet Mouthpiece", In: J.Acoust.Soc.Am. vol13 . 1942

National Semiconductor Corporation, "Linear Databook 1", p.2-272 -2-285 (LM12), 1988 Edition.

Raes, Godfried-Willem, "Kursus Akoestiek", Ghent University College 1982/2014, Internet: http://www.logosfoundation.org/kursus/4023.html

Raes, Godfried-Willem, <Bug> an automated Fluegelhorn, 2016.

Raes, Godfried-Willem, "Expression control in musical automates", 1977/2023,

Raes, Godfried-Willem, "Logos @ 50, het kloppend hart van de avant-gardemuziek in Vlaanderen", ed. Stichting Kunstboek, 2018

Rose,Nicholas and Holloway, Damien, "Finite element modeling of brass musical instruments', in: Proceedings of Acoustics, Fremantle, Australia 2012.

Smith, Bob H., "An Investigation of the Air Chamber of Horn Type Loudspeakers", in: The Journal of the Acoustical Society of America 25, 305-312 (1953); https://doi.org/10.1121/1.1907038

Cost calculation for <Cornalto>:

1. Parts and components

| Eb alto saxhorn | brought in by Alain Van Zeveren |

p.m.

|

| Steel | 2.5 €/kg - 12kg |

30.00

|

| Solenoids | 3 Banggood 12V, 1.5 Ohm |

99.00

|

| Membrane Compressor | 1 Omnitronic driver, ED-100T, 3/8" 18TPI mounting thread, 16 Ohms |

180.00

|

| 35 mm nut (1 3/8" - 18 TPI) | 1 (for tightening with a 35-50 mm hook wrench) |

27.00

|

| Brass staff-material | 100 mm |

3.00

|

| Soft PVC endcaps | 3 |

0.60

|

| M4 shock absorbers MF | 12 |

36.00

|

| M4 x 8 cylinder bolts | 15 |

9.50

|

| M6 x 50 cylinder bolts / nuts | 6 |

12.00

|

| M5 x 35 cylinder bolts / nuts | 4 |

4.00

|

| LM12 amplifier 150W sine | 1 |

150.00

|

| Mean Well SMPS 7.5V 20A | 1 |

75.00

|

| Mean Well SMPS 5V 20A | 1 |

75.00

|

| Polo, PCB-films | 3 |

75.00

|

| Cyanoacrylate glue | 1 (Loctite 401, 3g) |

4.00

|

| PCB Hub board | 3 analog in, 4 pulse/hold outputs, 3 outs, midi-in, differential thru, TTL midi out PIC 18F2620, 5V-2A power supply module, Weidmueller connectors |

355.00

|

| PCB Generator board | 2 16 bit PIC 24EP128MC202, 4 low noise op amps, 2 Burr-Brown multipliers, Weidmueller connectors, 1% precision resistors, 5 inductors |

435.00

|

| IEC Mains power entry | Schaffner FN-372 6 (230 V - 6 A) with switch and fuse |

13.50

|

| Faston connectors, blue/red | 35, power supply wiring |

11.00

|

| Wire | 10 m, 0.75 mm2, 1.5 mm2, coaxial/screened |

5.00

|

| Waco connectors, snap in | 2 5-contacts, 1 3-contacts |

3.00

|

| Wiring | 30 m of mounting wire in coded colors |

18.00

|

| Heatshrink tube | Polyolefine 1 m |

6.00

|

| Felt 10 mm thick | for mounting and dampening |

2.00

|

| 6 mm shock absorbers | 2 (LM12 power amp board) |

8.00

|

| 3 mm shock absorbers | 4 (waveform generator board) |

12.00

|

| M 10 stainless steel bolts and nuts | 2 |

6.00

|

| Polycarbonate 8mm thick |

2.50

|

|

| Mounting feet, M10 threads | 4, with two nuts each |

14.00

|

| Zinc sulphate spray can | 1 |

15.00

|

| Zinc sulphate primer paint | 250 ml |

12.00

|

| Subtotal parts: |

1698.10

|

2. Consumables

| Cobalt 3mm drill bits | 1 |

3.50

|

| Cobalt 4mm drill bits | 1 |

3.80

|

| Cobalt 5mm drill bits | 1 |

4.00

|

| Cobalt 8mm drill bits | 1 |

9.00

|

| TIG welding materials | Argon gas and Tungsten/Thorium electrodes |

10.00

|

| Cutting disks | 2 (A60 T-BF41 125 x 1.0 x 22.2 |

8.00

|

| Flap disc, 160mm | 1 |

12.00

|

| Sanding disks and paper | 1 |

4.00

|

| TIG welding nozzle, nr.5 | 1 |

12.00

|

| Cutting oil (spray can) | 1 |

1.00

|

| Solder Pb/Sn 40/60 & leadfree | 5 m |

5.00

|

| Steel welding electrodes | 10 3.2 mm |

8.00

|

| Aceton | 0.5 l |

4.00

|

| Etching baths | Fe2Cl3 1 liter |

5.00

|

| Methanol | 0.25 l |

2.00

|

| NaOH sollution | 0.5 l |

1.00

|

| 35 mm hole saw | 1 |

27.00

|

| Saw blade, ridgid | 1 |

4.70

|

| Subtotal: |

114.00

|

3. Depreciations on tools and equipment used (calculated over 1 month)

| Tool | Value | Depreciation percentage / month | |

| Tektronix TDS2024C | 3500 | 2.77% |

97.00

|

| TIG welding equipment | 2000 | 2.77% |

55.00

|

| Contimex Lathe | 2500 | 2.77% |

69.50

|

| Cobalt saw | 2800 | 2.77% |

77.50

|

| Soldering equipment | 1000 | 2.77% |

27.50

|

| Proton+ Laptop & ICD | 1800 | 2.77% |

25.00

|

| Lab power supply | 380 | 2.77% |

5.00

|

| Odin column drill | 6000 | 0.92% |

27.50

|

| Welding table | 2500 | 0.92% |

11.50

|

| Subtotal: |

395.50

|

4. Labor and design (45,-/hour)

| 28.06.2021 | 4 h |

180.00

|

| 01.07.2021 | 2 h |

90.00

|

| 02.07.2021 | 8 h |

360.00

|

| 03.07.2021 | 5 h |

225.00

|

| 04.07.2021 | 8 h |

360.00

|

| 05.07.2021 | 1 h |

45.00

|

| 06.07.2021 | 6 h |

270.00

|

| 07.07.2021 | 8 h |

360.00

|

| 09.09.2021 | 6 h |

270.00

|

| 10.09.2021 | 5 h |

225.00

|

| 11.09.2021 | 6 h |

270.00

|

| 12.09.2021 | 4 h |

180.00

|

| 13.09.2021 | 8 h |

360.00

|

| 14.09.2021 | 1 h |

45.00

|

| 18.09.2021 | 1 h |

45.00

|

| 20.09.2021 | 3 h |

135.00

|

| 21.09.2021 | 4 h |

180.00

|

| 24.09.2021 | 4 h |

180.00

|

| 25.09.2021 | 5 h |

225.00

|

| 01.10.2021 | 1 h |

45.00

|

| 02.10.2021 | 1 h |

45.00

|

| 03.10.2021 | 6 h |

270.00

|

|

04.10.2021 |

8 h |

360.00

|

| 05.10.2021 | 8 h |

360.00

|

| 06.10.2021 | 8 h |

360.00

|

| 07.10.2021 | 8 h |

360.00

|

| 08.10.2021 | 6 h |

270.00

|

| 09.10.2021 | 7 h |

315.00

|

| 10.10.2021 | 4 h |

180.00

|

| Subtotal: | 152 h |

6.840,00

|

Total value: 9.047,60-

[EOF]