|

Pitched

Percussion Robot

|

|

<Tubo>

Godfried-Willem

RAES

2019 /

2020

|

<Tubo>

Aluminum tubes were used in earlier robots such as our <Tubi>,

a quartertone instrument. In 2019, we did build the

Plus-Minus project, using aluminum tube of greater thickness. Extending

the register on the low side, appeared impossible using the same type of tube.

When the tubes are made longer, the second overtone becomes dominant. Hence

the idea to apply mensuring on the proportions. Thus this instrument uses aluminum

pipes of different diameters. The tube lenghts can be calculated using following

formula, valid as long as the tube length is at least 10 times larger than the

diameter.  The frequency

for the first overtone, given by Olson as 2.758 times the fundamental frequency,

after our measurements, it ought to be 2.705 times the fundamental. This is

the pitch perceived on the attack of the tube. It can be measured exactly by

suspending the tube exactly in the centre, the first overtone having a node

there.

The frequency

for the first overtone, given by Olson as 2.758 times the fundamental frequency,

after our measurements, it ought to be 2.705 times the fundamental. This is

the pitch perceived on the attack of the tube. It can be measured exactly by

suspending the tube exactly in the centre, the first overtone having a node

there.

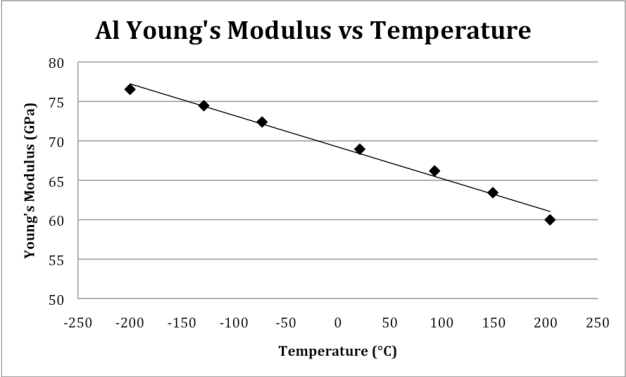

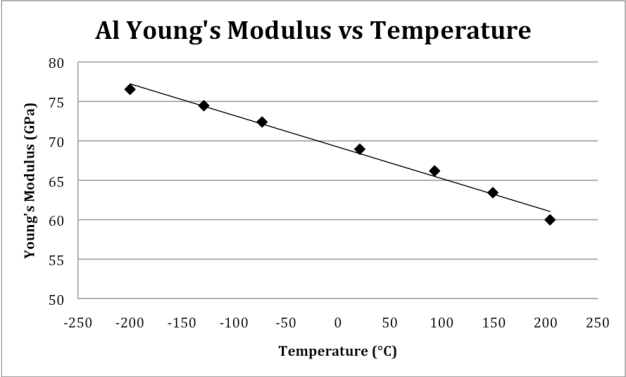

Note that the modulus of elasticity (Youngs modulus) is temperature dependent.

This curve illustrates this dependency for aluminum:  The variation is quite small, but when tuning, one has to be carefull to cool

the tubes to ambient temperature before checking the pitch. Grinding and sanding

makes the tubes very hot... A bucket of cold water next to the sander is of

great help here.

The variation is quite small, but when tuning, one has to be carefull to cool

the tubes to ambient temperature before checking the pitch. Grinding and sanding

makes the tubes very hot... A bucket of cold water next to the sander is of

great help here.

The alloy used for the tubes is AlMgSi 0.5 F22 (Werkstof nummer: 3.3206, International

6063)

The composition is: 0.3-0.6% Si , 0.1-0.3% Fe, 0.1% Cu, 0.1% Mn, 0.35-0.6%

Mg, 0.05% Cr, 0.15% Zn, 0.15% Ti, 0.15% other elements, saldo to make 100% is

Al

An alternative alloy is AlMgSi 1 (Werkstof nummer: 3.2315, international 6082)

Composition: 0.7-1.3% Si , 0.5% Fe, 0.1% Cu, 0.4-1% Mn, 0.6-1.2% Mg, 0.05%

Cr, 0.25% Zn, 0.1% Ti, 0.15% other elements, saldo to make 100% is Al. However

this alloy is only available in tubes 57/47. Moreover, we couldn't obtain this

alloy as it appears not to be a stock item.

Tube sizing:

60mm / 50mm tube: (2.331 kg/m)

| midi note |

frequency (Hz) |

length (mm) |

suspension |

m constant |

weigth kg |

| 48 |

130.8 |

1627.5 |

365 |

1.1172 |

3.793 |

| 49 |

138.6 |

1581 |

354.5 |

1.1169 |

3.685 |

| 50 |

146.8 |

1536 |

344 |

1.1169 |

3.580 |

| 51 |

155.6 |

1491 |

334 |

1.115 |

3.476 |

| 52 |

164.8 |

1449 |

325 |

1.1157 |

3.378 |

| 53 |

174.6 |

1407 |

315.5 |

1.1145 |

3.280 |

55mm / 45mm tube: (2.200 kg/m)

| midi note |

frequency (Hz) |

length (mm) |

suspension |

m constant |

weigth kg |

| 54 |

184 |

1298 |

291 |

1.1045 |

2.856 |

| 55 |

195 |

1261 |

283 |

1.1044 |

2.774 |

| 56 |

207.6 |

1225 |

274.5 |

1.1033 |

2.695 |

| 57 |

220 |

1190 |

267 |

1.104 |

2.618 |

| 58 |

233.1 |

1156 |

259 |

1.1037 |

2.543 |

| 59 |

246.9 |

1123 |

252 |

1.1036 |

2.471 |

50mm / 40mm tube: (1.908 kg/m)

| midi note |

frequency (Hz) |

length (mm) |

suspension |

m constant |

weigth kg |

| 60 |

261.6 |

1040 |

233 |

1.1129 |

1.955 |

| 61 |

277 |

1010 |

226.5 |

1.112 |

1.906 |

| 62 |

293 |

980 |

220 |

1.1092 |

1.848 |

| 63 |

311 |

952 |

213.5 |

1.1089 |

1.801 |

| 64 |

329 |

925 |

207 |

1.1092 |

1.746 |

| 65 |

349 |

898 |

201 |

1.1075 |

1.698 |

40mm / 30mm tube: (1.484 kg/m)

| midi note |

frequency (Hz) |

length (mm) |

suspension |

m constant |

weigth kg |

| 66 |

369 |

773 |

173 |

1.1135 |

1.136 |

| 67 |

391 |

751.5 |

168.5 |

1.115 |

1.108 |

| 68 |

415 |

730 |

163.7 |

1.1146 |

1.076 |

| 69 |

440 |

709 |

159 |

1.1139 |

1.048 |

| 70 |

466 |

689 |

154.5 |

1.1145 |

1.018 |

| 71 |

493 |

668.5 |

150 |

1.1116 |

0.988 |

35mm / 25mm tube: (1.272 kg/m)

| midi note |

frequency (Hz) |

length (mm) |

suspension |

m constant |

weigth kg |

| 72 |

523 |

602.5 |

135 |

1.1121 |

0.765 |

| 73 |

554 |

585 |

131 |

1.1107 |

0.743 |

| 74 |

587 |

567 |

127 |

1.1055 |

0.721 |

| 75 |

622 |

551 |

123.5 |

1.106 |

0.701 |

| 76 |

659 |

535 |

120 |

1.1047 |

0.680 |

| 77 |

698 |

519 |

116 |

1.1015 |

0.660 |

30mm / 20mm tube: (1.060 kg/m)

| midi note |

frequency (Hz) |

length (mm) |

suspension |

m constant |

weigth kg |

| 78 |

739.99 |

466.5 |

104.6 |

1.1247 |

0.494 |

| 79 |

783.99 |

453.6 |

101.7 |

1.1266 |

0.481 |

| 80 |

830.61 |

440 |

98.65 |

1.1231 |

0.466 |

| 81 |

880 |

426.5 |

95.6 |

1.118 |

0.441 |

| 82 |

932.33 |

414.5 |

92.93 |

1.1187 |

0.439 |

| 83 |

987.77 |

402 |

90.13 |

1.1149 |

0.426 |

| 84 |

1046.5 |

391.5 |

87.77 |

1.1203 |

0.415 |

| 85 |

1108.7 |

380 |

85.2 |

1.1182 |

0.403 |

| 86 |

1174.66 |

369 |

82.7 |

1.1171 |

0.391 |

| 87 |

1244.51 |

357 |

80 |

1.1078 |

0.378 |

| 88 |

1318.5 |

347.5 |

77.9 |

1.112 |

0.368 |

| 89 |

1396.9 |

336 |

75.3 |

1.1014 |

0.356 |

| 90 |

1479 |

326.5 |

73.2 |

|

0.346 |

| 91 |

1567 |

316.8 |

71.03 |

|

0.336 |

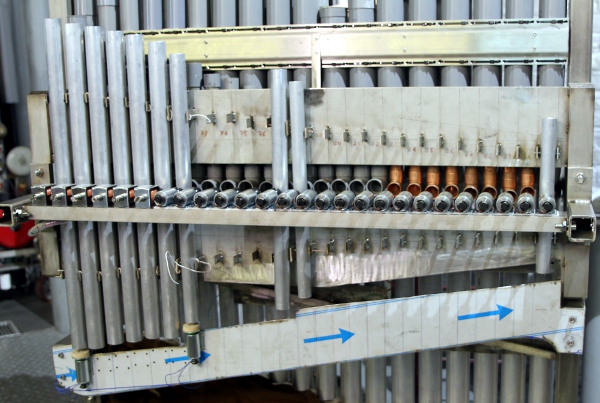

The tubes are suspended on their nodal point at both ends. Thus we could avoid

the swinging of the tubes and as a consequence, unreliable operation on repeated

notes. This is a problem we had on the <Tubi> robot.

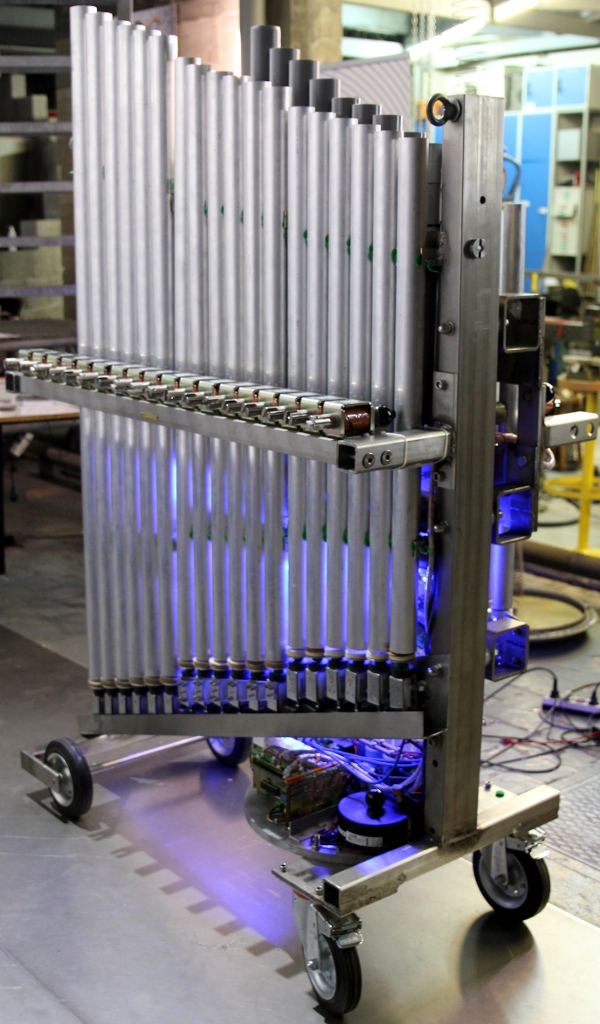

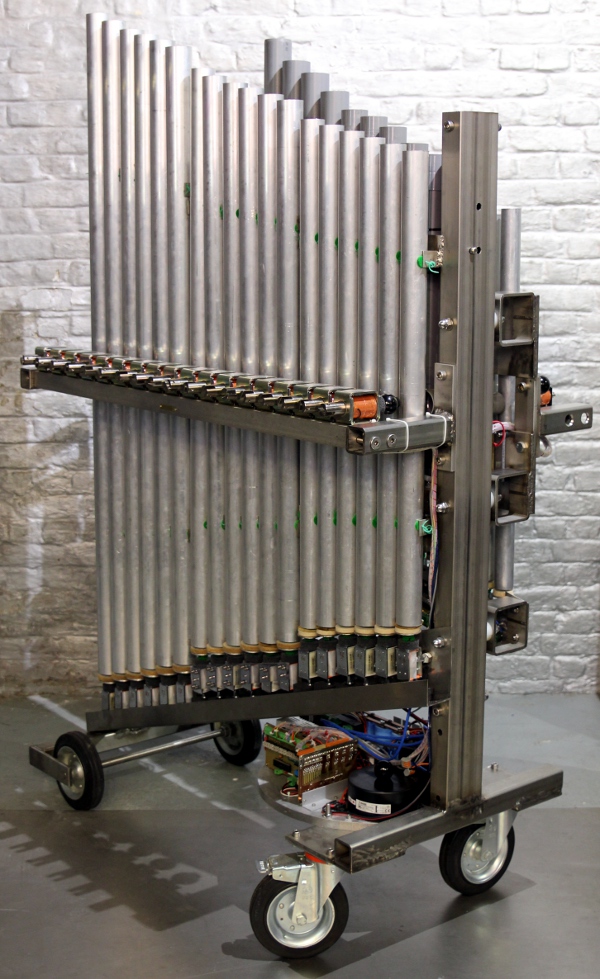

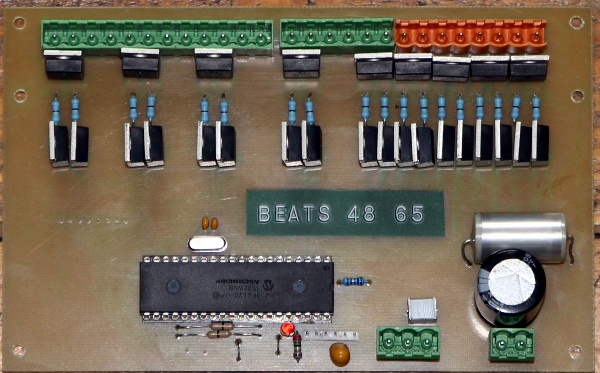

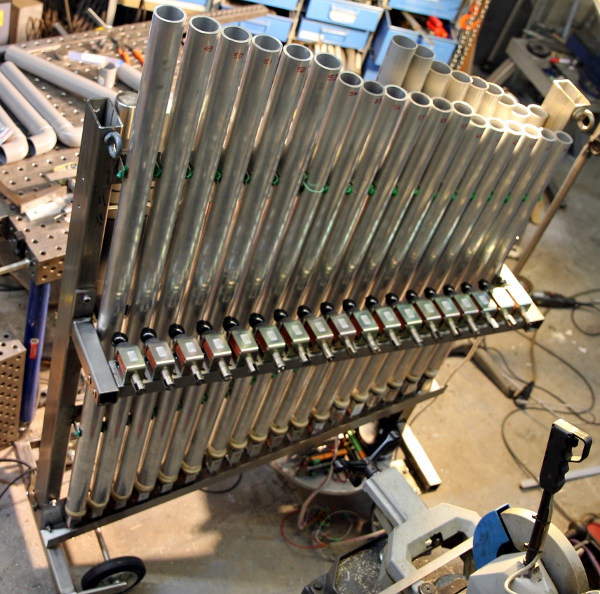

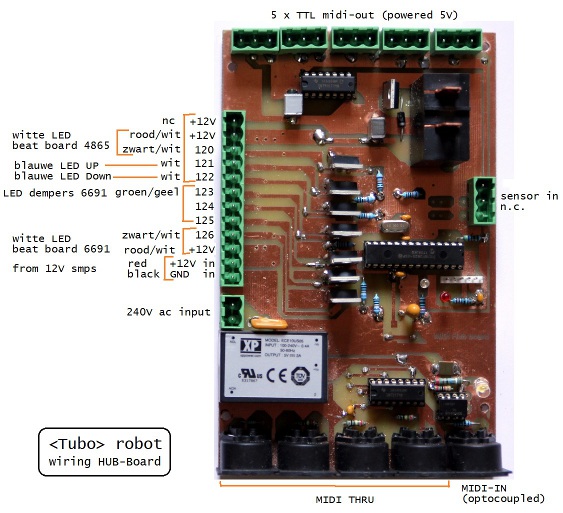

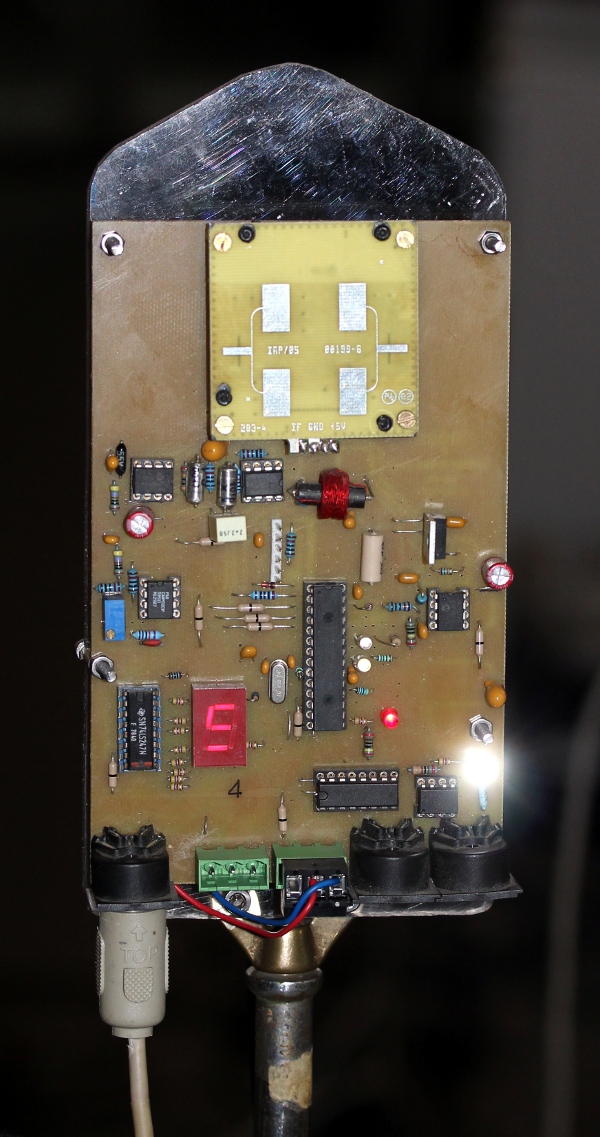

This robot uses seven fast PIC microprocessors; five 8-bit controllers and

two 16-bit controllers, handling following tasks:

- Midi parsing, hub and light control (18F2620)

- Beaters for notes 48 to 65 (18F4620)

- Dampers for notes 48 to 65(18F4620)

- Beaters for notes 66 to 91 (18F4620)

- Dampers for notes 66 to 91 (18F4620)

- Vibrato motor control 48 to 65 (24EP128MC202)

- Vibrato motor control 66 to 91 (24EP128MC202)

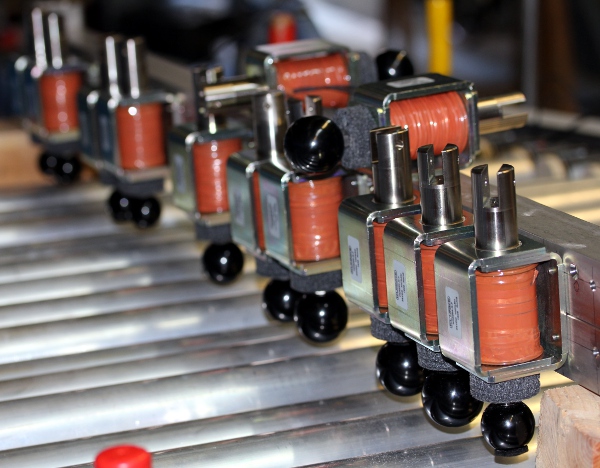

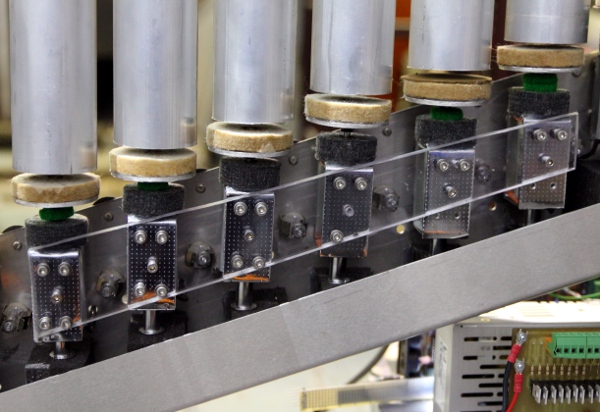

Beaters:

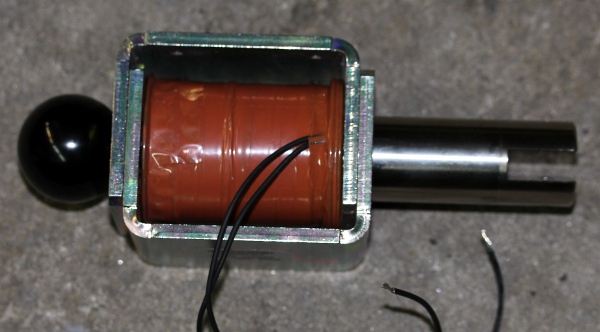

The beaters for the tubes were selected such that the mass of the moving anchor

is in the order of one fifth of mass of the tube to be struck. This condition

made the use of pretty hefty solenoids for the low notes mandatory. Hence our

selection of Kuhnke solenoids, type HD8286-RF for the notes 48 to 65 and type

HD6286-RF for 66 to 71. For the higher notes, Tremba 24V solenoids were used.

The beaters have adjustable bakelite knobs (threaded) covered with a layer of

felt. These solenoids are specified to operate at 24V (100% duty cycle). As

we wanted to implement a wide range of dynamic, we operate them on a 100V voltage.

At that voltage, the pulse durations required to activate the coils range from

3.5ms to 30ms. Microcontrollers (PIC 18F4620) are used to generate these pulses

proportional to the required velocity. As this robot uses many and heavy solenoids,

it became a pretty expensive robot to construct.

It appeared of utmost importance to build the instrument such that the beaters

strike the tubes exactly at the point halfway their length, thus eliminating

as much as possible the sounding of the first (inharmonic) overtone, having

a nodal point at that place. The circuit controlling the operation of the beaters

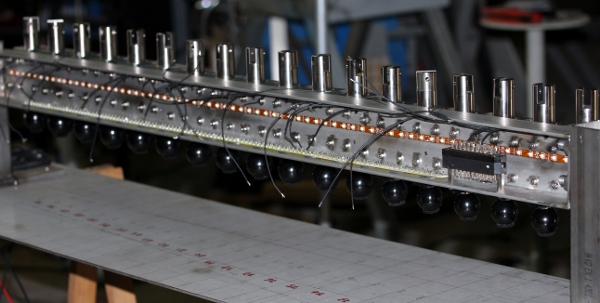

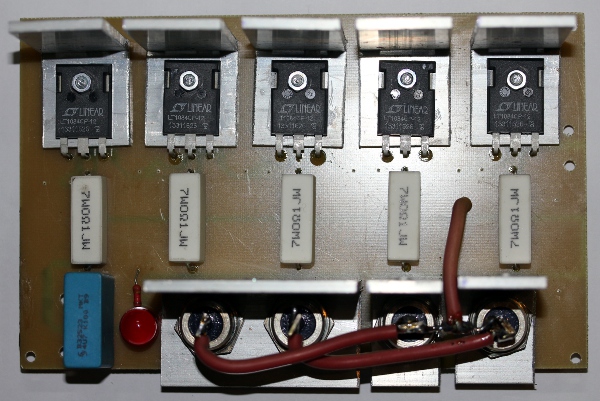

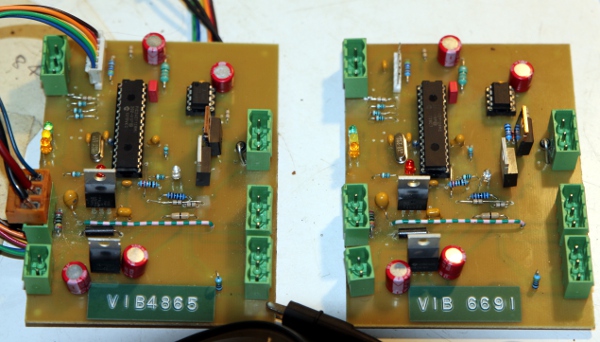

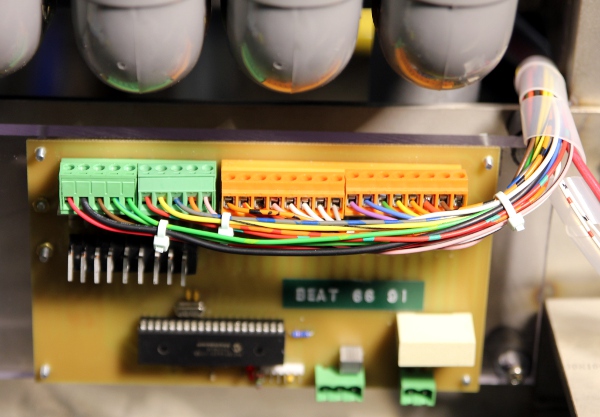

is:  Two of these

boards are used for the beaters. The MOSFET's used here are IRL640 types and

the clamping diodes MUR620C.

Two of these

boards are used for the beaters. The MOSFET's used here are IRL640 types and

the clamping diodes MUR620C.

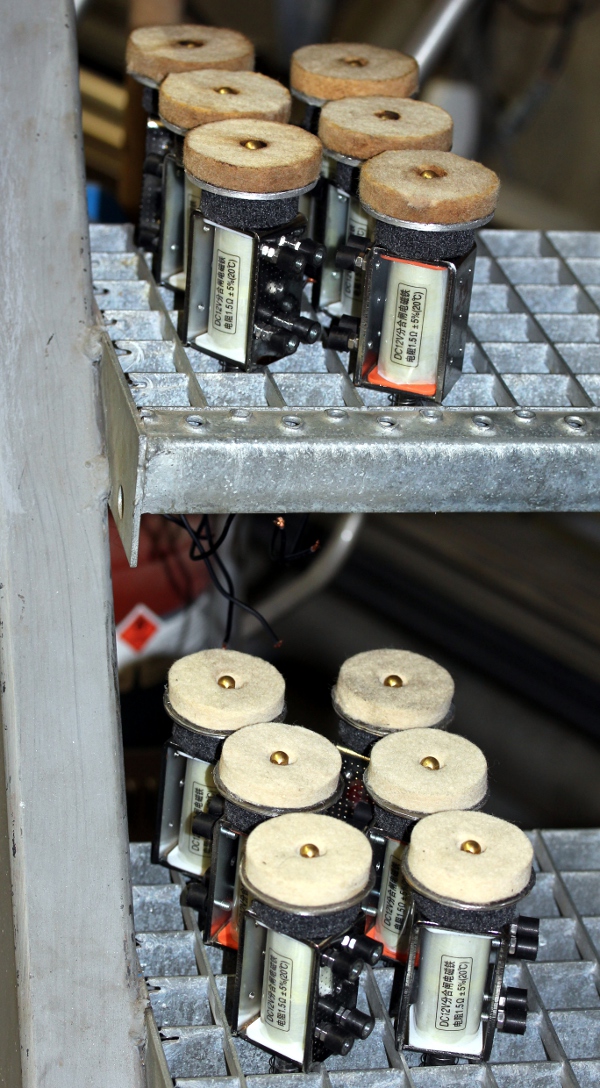

Dampers:

The dampers make this robot very different than the earlier <Tubi> robot,

where we did not use any kind of damping. With the dampers -the damping can

be controlled by the users- the robot becomes a valid alternative for our <Vibi>

robot, an automated vibraphone.

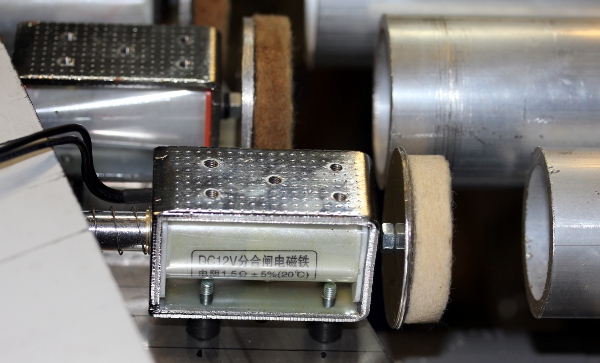

To reduce costs a bit, we used cheap Chinese long-stroke magnets for the dampers

on the lowest 18 notes. At Banggood they go for ca. 17$ a piece. They are rated

for 12 V at a duty cycle of 5%. The DC resistance of the winding is 1.5 Ohm.

Applying the handy formula given in the Kuhnke catalog:  we

can derive that the nominal voltage for the coils is 5.8 V. However, if we leave

them activated for a long time (> 5 minutes) they become very hot and their

resistance goes up to 2.2 Ohm. Thus, to keep things safe, the continuous voltage

should be kept below 5 V. At that voltage, the coils still draw 3.33 A of current

and consume 16.6 W. With such figures in mind, it's easy to understand why we

limited the polyphony of this robot to four notes in the low register...

we

can derive that the nominal voltage for the coils is 5.8 V. However, if we leave

them activated for a long time (> 5 minutes) they become very hot and their

resistance goes up to 2.2 Ohm. Thus, to keep things safe, the continuous voltage

should be kept below 5 V. At that voltage, the coils still draw 3.33 A of current

and consume 16.6 W. With such figures in mind, it's easy to understand why we

limited the polyphony of this robot to four notes in the low register...

To protect the damper solenoids used for the note range 48 to 65, we applied

an old trick: wiring a 35 W - 12 V Halogen bulb in series with the coils, automatically

generates a high striking force, going down quickly as the bulb starts glowing,

thus increasing its resistance by a factor 10. The time the dampers are active

can be controlled by the user, as we mapped it on the release byte accompanying

the note-off commands. If note-off with release can not be used (most commercial

sequencer software seems to ommit its implementation), we provided a midi controller

(#25) to set the amount of damping.

These solenoids drive circular felt covered plates mounted at the underside

of the tubes. The felt here is 10 mm thick, a requirement for silent operation.

Fall back of the anchors is also dampened with thick felt.

For the notes 66 up to 77, we used Tremba solenoids. For the notes 78 to 81,

we used Lucas Ledex solenoids and for the notes 82 up to 91 Black Knight types,

all rated for 12V at 100% duty cycle. As a consequence, here we could go without

the halogen bulbs. Of course, response speed is slower here.

A sustain controller (#64) is implemented in the firmware to disable the damper

mechanism alltogether.

The circuit to control the dampers (two boards are used) is identical to the

one described above for the beaters. However components are different. The MOSFET's

here are IRLZ34NPBF and here we did not mount clamping diodes, but MOV's. (Epcos

B72210S0140K101)

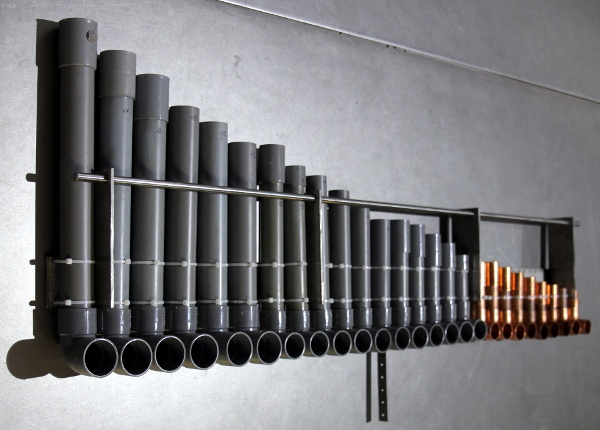

Resonators:

In <Tubo> pipe resonators are coupled to all tubes up to note 91. This

highly reinforces the fundamental pitch of the tubes. Due to the high mass of

the tubes, the sustain of the tones is very long. In order to limit building

height of the instrument, we used closed pipe resonators for the lowest nine

notes and open pipes for the higher notes. All resonators were made from PVC

tube material, except for the highest octave, where we used brass and copper.

In orchestrations for the logos robotorchestra of orchestral music, <Tubo>

makes a better alternative for the celesta. It can also be used as a replacement

for vibraphone parts.

Vibrato:

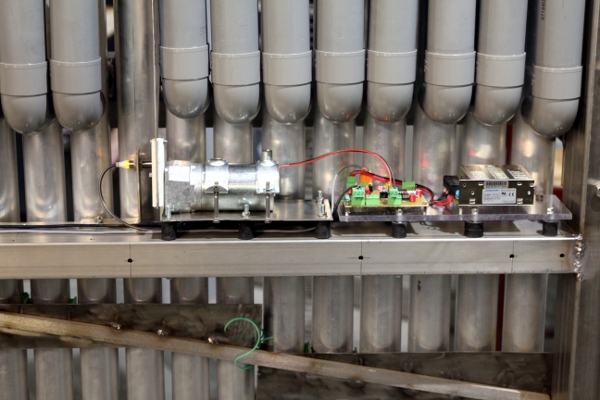

The resonators were mounted on an assembly that can move over a limited trajectory.

By automating this movement using two DC-motors with an excentric shaft, we

succeeded in building a quite novel vibrato mechanism. Modulating the distance

between the open ends of the resonators and the aluminum pipes leads to a vibrato

quite simular to that implemented on the vibraphone. The speed of the vibrato

can be controlled. Due to the high mass of the resonator assemblies, we had

to limit the maximum vibrato speed to slightly over 2.5 Hz. Extreme slow vibrato

is perfectly possible. When the vibrato mechanism is switched off, the motors

will slow down and return the resonators to their optimum coupled position automatically.

One motor steers the vibrato for the notes 48 to 65 and another one the notes

66 to 91. Hence we implemented two separate controllers (#20 and #21) for the

vibrato speed. Controller #22 is implemented as well, and will set the vibrato

speed for both motors together.

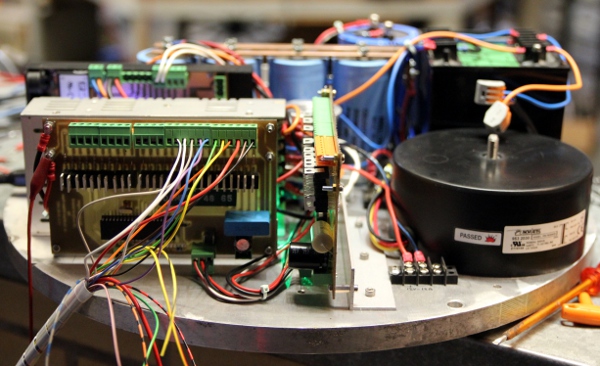

The circuit used to drive the vibrato mechanism is:  Here

a 16-bit PIC microcontroller is used.

Here

a 16-bit PIC microcontroller is used.

MIDI-hub board:

All circuits shown above get their 5V power from a MIDI-hub board, controlling

the lights and taking care of MIDI parsing. This board also houses a high current

relay used to switch the high power supplies on. Here is the circuit:

Power Supply:

This robot was finished and completely ready for playing in february 2020.

In 2021 we added a radar board such that the <Tubo> robot can now be

setup as an autonomous interactive sound sculpture. Details on the

radar board can be found here.

Here is the circuit:

Mapping:

Midi note range: 48-91

Note Off commands with release are required to activate the dampers. If noteoff

with release cannot be used (many sequencers do not implement it), the release

values used can be set with controller 25. This value will also be used when

noteon commands with velo=0 are used to switch notes off. It is permissible

to only send note-on commands, if dampers are not used. It is also permissible

to only send noteoff+release commands, causing the tubes to be played with the

dampers only. This gives a rather soft tone and sounds the pitch of the air

column in the tubes together with their fundamental note.

Note On commands: Velocity is implemented and has a wide controll range. Value

32 corresponds to a musical 'p' (76dBA), a 'f' (90dBA) is reached with value

64 and a 'ff' (102dBA) with value 96. Note that repetition rate is a function

of velocity! The lower the velocity values used, the faster the repetition rates

can be. Repetition rates also depend on pitch, as they are a function of the

anchor mass. So low notes have inherently slower repetition rates than high

notes.

Lights are mapped on midi-notes as follows:

- note 120: White LED strip under the low side beater assembly

- note 121: Blue LED spot upwards from bottom power supply

- note 122: Blue LED spot downwards from bottom power supply

- note 123: Blue LED strip under the high side damper assembly

- note 124: Blue LED multi-LED spotlight, inside on high damper assembly

- note 125: Blue LED multi-LED spotlight, outside on high damper assembly.

- note 126: White LED strip under the high side beater assembly

The velocity byte, in this case, steers the flashing speed. With velocity =

127, the lights are full on, without flashing.

The key pressure command controls the repetition rate for the lights, if switched

on. This feature is not implemented for the beaters.

Controllers:

- Controller 20: Steers the vibrato speed for the note range 48 to 65

- Controller 21: Steers the vibrato speed for the note range 66 to 91

- Controller 22: Steers the vibrato speed for both motors together. However,

sync is not guaranteed.

- Controller 25: Steers the damping time for all notes 48 to 91. Default value

= 64

- Controller 64: sustain on/off switch. When 0 (off), the damper mechanism

will be active. When >0 (on), the damper mechanism is disabled. The default

value is OFF.

- Controller 66: is used to switch the solenoid power on or off. It will also

release all dampers and reset controllers to default values. On cold boot,

this controller is OFF.

- Controller 123: all notes off command. Damps all sounding notes (unless

sustain is on) and switches off lights. It stops both vibrato motors. It does

not reset any controllers.

The midi listen channel is 4 (counting 0-15)..

Techical specifications:

- size: h = 1600 mm, w = 1272 mm, d = 620 mm

- weigth: 228 kg

- power: 240V ac

- tuning: equal temperament based on A=440 Hz

- Ambitus: 3 1/2 octaves 48-91

- Maximum sound pressure level: >106dbA

- control: MIDI input , channel 4

- Insurance value: (construction cost) 56.000 Euro

Design and construction: dr.Godfried-Willem

Raes

Collaborators on the construction of this robot:

- Bert Vandekerkhove (mounting)

- Kristof Lauwers (coding)

- Lara Van Wynsberghe (tuning)

- Mattias Parent (workshop)

- Moniek Darge

- Peter Van Lancker

- Laura Maes

Music composed for <Tubo>:

- Godfried-Willem Raes 'Eindjes' (2019)

- Godfried-Willem Raes 'Rad4Tub' (2021, interactive and embedded composition

for Radar4)

Nederlands:

<Tubo>

Bouwdagboek:

Omdat ons vaak wordt gevraagd hoeveel werk en tijd kruipt in,

en nodig is voor, het bouwen van een muzikale robot, hebben we ook voor <Tubo>

een uitgebreid en gedetailleerd bouw- en onderhoudsdagboek bijgehouden: Dit

bouwdagboek is uitgebreider dan dat voor vele vroegere robots omdat we -wetend

dat ons einde stilaan naderbij komt- jongeren die in ons voetspoor zouden willen

treden zoveel mogelijk tegemoet wilden komen.

- 01.06.2019: eerste ideen en konkrete tekeningen aansluitend bij de bouw

van het Plus-Minus projekt.. Onderzoek naar de toepassingsmogelijkheden van

bidirektionele sleeplade magneten voor de kloppers. Zo stond het beschreven

in de eerste beschrijving van het <Tubo> bouwprojekt: "The tubes

have individual felt covered rubber beaters driven by solenoids as well as

individual dampers. Musical dynamics are implemented by applying pulse width

modulation techniques in the driver circuits both for the beaters and for

the dampers. For the lowest octave the weight of the beaters has to be ca.

1/5th of the weight of the tube to be struck. The beaters have to be covered

with a layer of felt. This condition necessitated the use of strong bidirectional

solenoids for the beaters. In organ windchests these solenoids are always

wired as:

If

the left winding gets current, the anchor moves to the left, with the right

coil powered, the anchor moves to the right side. If both coils are activated,

the magnetic fields cancel each other and no force is available from the anchor.

If we use this type of solenoid in the following configuration, however:

If

the left winding gets current, the anchor moves to the left, with the right

coil powered, the anchor moves to the right side. If both coils are activated,

the magnetic fields cancel each other and no force is available from the anchor.

If we use this type of solenoid in the following configuration, however: operation is quite different. When only one coil is activated, it will behave

as before, but when both coils are activated, the anchor will move to he center

and force will be available to keep it there, as both magnetic fields will

reinforce each other. By controlling the current over both coils independently,

we can make the coil operate as a linear motor."

operation is quite different. When only one coil is activated, it will behave

as before, but when both coils are activated, the anchor will move to he center

and force will be available to keep it there, as both magnetic fields will

reinforce each other. By controlling the current over both coils independently,

we can make the coil operate as a linear motor."

- 02.06.2019: Ontwikkeling veralgemeende software voor de berekening van de

stemming en dimensionering van de aluminium buizen. Hiervoor gebruiken we

de Power Basic Console Compiler.

- 03.06.2019: Aanmaak set proefbuizen ter bepaling van de materiaalkonstanten.

- 04.06.2019: Buizen voor de noten 60 tot 65 uit 50/40 buis precies gezaagd

en gestemd.

- 05.06.2019: Noten 66 tot 71 uit 40/30 buis gestemd.

- .

Hier zijn de

maten van de af te zagen lengtes:

Hier zijn de

maten van de af te zagen lengtes:

| midi noot |

frekwentie (Hz) |

lengte (mm) |

ophangpunt |

gewicht kg |

| 60 |

261 |

1040 |

233 |

1.955 |

| 61 |

277 |

1010 |

226.5 |

1.906 |

| 62 |

293 |

980 |

220 |

1.848 |

| 63 |

311 |

952 |

213.5 |

1.801 |

| 64 |

329 |

925 |

207 |

1.746 |

| 65 |

349 |

898 |

201 |

1.698 |

Om een goede grondtoon te verkrijgen moet het gewicht van de (zachte) hamers

minstens een vijfde zijn van het gewicht van de buis.

- 06.06.2019: Zes testbuizen, maat 40/30 nauwkeurig gestemd. Midi noten 66

tot 71. Hier zijn de maten van de af te zagen lengtes:

| midi noot |

frekwentie (Hz) |

lengte (mm) |

ophangpunt |

gewicht kg |

| 66 |

369 |

773 |

173 |

1.136 |

| 67 |

391 |

751.5 |

168.5 |

|

| 68 |

415 |

730 |

163.7 |

|

| 69 |

440 |

709 |

159 |

|

| 70 |

466 |

689 |

154.5 |

|

| 71 |

493 |

668.5 |

150 |

|

- 07.06.2019: Berekeningssoftware aangepast en geperfectioneerd. Zes testbuizen,

maat 35/25 gestemd. Midi noten 72 tot 77. Deze buizen kunnen ook in de bestaande

struktuur van Plus Minus opgehangen worden.

| midi noot |

frekwentie (Hz) |

lengte (mm) |

ophangpunt |

gewicht kg |

| 72 |

523 |

602.5 |

135 |

|

| 73 |

554 |

585 |

131 |

|

| 74 |

587 |

567 |

127 |

|

| 75 |

622 |

551 |

123.5 |

|

| 76 |

659 |

535 |

120 |

|

| 77 |

698 |

519 |

116 |

|

- 08.06.2019: Meting van het minimaal noodzakelijk gewicht van de hamers.

Blijkt dat dit minimaal 1/10, maximaal 1/5 van de massa van de aan te slane

buizen moet zijn voor een optimaal grondtonige klank. De 'wet van de klok'

blijkt ook hier van kracht. De hamers moeten ook voorzien worden van een dikke

laag leder of vilt.

- 09.06.2019: Ontwerp en berekening van een terugslagmechanisme voor de hamers

in het laagste oktaaf, gebruik makend van bidirektionele registertrekmagneten

zoals gebruikt in de orgelbouw.

- 10.06.2019: Eerste tentatieve maatvoering uitgewerkt (voor ambitus 60 -

96):

| eerste rij buizen |

tweede rij buizen |

| 6 x 50 = 300 |

2 x 35 = 70 |

| 6 x 40 = 240 |

19 x 30 = 570 |

| 4 x 35 = 120 |

22 x 10 = 220 |

| 17 x 10 = 170 |

|

| breedte = 850 |

breedte = 860 |

Op deze wijze opgebouwd

kan de breedte van de robot wellicht beperkt blijven tot 1 meter.

Op deze wijze opgebouwd

kan de breedte van de robot wellicht beperkt blijven tot 1 meter.

- 11.06.2019: Proefopstelling gemaakt met haakjes. We hebben hier wel wat

problemen met zinderingen op de ophangstaafjes.

Viltjes helpen wel wat, maar lossen het probleem niet helemaal op.

Viltjes helpen wel wat, maar lossen het probleem niet helemaal op.

- 12.06.2019: Experimenten met buisresonatoren teneinde de grondtonigheid

te versterken. De klank gaat dan wel meer naar een vibrafoon klinken. Open

buis resonatoren geven iets meer resonantie (volume) dan gesloten buizen,

zoals blijkt uit onze experimenten met de buis voor midi noot 60. Buisresonatoren

zijn heel zeker een muzikale verbetering. In principe zouden we ook draaiende

kleppen kunnen voorzien, zoals op een vibrafoon. Softshift magneten op elke

resonator buis zouden de ideale oplossing zijn, maar daarvoor hebben we de

middelen niet meer... ( Met dank aan Sven Gatz die de samenstelling van de

ministeriele advieskommissies niet van korruptie dierf te saneren).

- 13.06.2019: Overweging tot uitbreiding van het instrument naar de laagte

toe. Ambitus 48 - 96 of, 48-84. Zodoende kan het instrument ook als celesta

dienst doen. Ontwerp T-vormige resonatoren in PVC. Elektromagneten voor de

hamers besteld bij Laukhuff.

Enkele

bugs gedood in de berekeningssoftware. De nieuwe tessituur zou dan kunnen

worden:

Enkele

bugs gedood in de berekeningssoftware. De nieuwe tessituur zou dan kunnen

worden:

- 14.06.2019: Nieuwe en betere test- en meetopstelling gemaakt. De resonatorbuizen

moeten zeker dezelfde diameter hebben dan de klankbuizen. De testopstelling

voor midi noot 60 werkt prima nu. Software aangepast voor de berekening van

de resonators. Resonatoren hebben vanaf noot 87 weinig zin meer. De lengte

van de resonator wordt kleiner dan vijfmaal de doorsnede ervan wat een geringe

resonantie voor gevolg heeft. Foto van de betere testmontage:

En ook vier resonatoren voor de noten 60, 61,62, en 63 gemaakt, gestemd en

getest:

En ook vier resonatoren voor de noten 60, 61,62, en 63 gemaakt, gestemd en

getest:  De diameter van de resonatoren moet overeenstemmen met die van de aluminium

klankbuis.

De diameter van de resonatoren moet overeenstemmen met die van de aluminium

klankbuis.

- 15.06.2019: Vijf duwmagneten besteld bij Conrad.

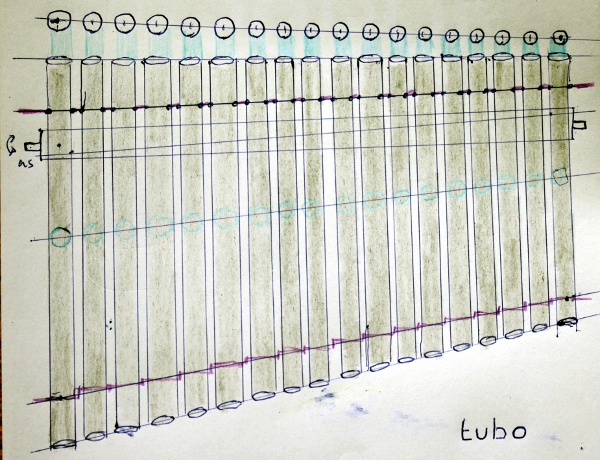

- 16.06.2019: Eerste schets van de mogelijke opbouw...

Gestemde buizen afgewerkt tot en met noot 84. Alle nodale gaten voor noten

60 tot 84 geboord en afgewerkt. Voor de uitbreiding naar de laagte is het

wachten op informatie over de leverbaarheid van de aluminium buizen. Zo stilaan

hebben we een zicht op de werklast voor de konstruktie van deze robot. Hij

zal pas in 2020 beschikbaar kunnen komen...

Gestemde buizen afgewerkt tot en met noot 84. Alle nodale gaten voor noten

60 tot 84 geboord en afgewerkt. Voor de uitbreiding naar de laagte is het

wachten op informatie over de leverbaarheid van de aluminium buizen. Zo stilaan

hebben we een zicht op de werklast voor de konstruktie van deze robot. Hij

zal pas in 2020 beschikbaar kunnen komen...

- 17.06.2019: Buizen voor noten 85 en 86 gezaagd en gestemd. Experimentele

opstelling met buismontage in de slagrichting. Dit zou de konstruktie aanzienlijk

vereenvoudigen. Er zijn wel 10 mm dikke viltringen nodig voor de montage.

Akoestisch gezien

is en blijft dit evenwel een minderwaardige oplossing. Wel kunnen we nog overwegen

om de ophanggaten (nu 3mm) te vergroten, zodat we de schroefdraad kunnen overtrekken

met kunststof of rubber. Na te meten valt in welke mate dit een invloed heeft

op de stemming. Vijf Tremba solenoids type ZMF-3865d-15.002 24V DC geleverd

door Conrad. Deze zouden geschikt moeten zijn voor de dempers. Resonatoren

prototypes gemaakt voor noot 66 (40 mm PVC buis) en noot 72 (32 mm PVC buis).

Overwogen kan ook worden om het mechanisme van een doppler-reflektie tremulant

zoals we die aantreffen in harmoniums, te gebruiken voor de noten vanaf 78.

Zo'n geautomatiseerde tremulant bouwden we al eens voor onze <Harmo>

robot.

Akoestisch gezien

is en blijft dit evenwel een minderwaardige oplossing. Wel kunnen we nog overwegen

om de ophanggaten (nu 3mm) te vergroten, zodat we de schroefdraad kunnen overtrekken

met kunststof of rubber. Na te meten valt in welke mate dit een invloed heeft

op de stemming. Vijf Tremba solenoids type ZMF-3865d-15.002 24V DC geleverd

door Conrad. Deze zouden geschikt moeten zijn voor de dempers. Resonatoren

prototypes gemaakt voor noot 66 (40 mm PVC buis) en noot 72 (32 mm PVC buis).

Overwogen kan ook worden om het mechanisme van een doppler-reflektie tremulant

zoals we die aantreffen in harmoniums, te gebruiken voor de noten vanaf 78.

Zo'n geautomatiseerde tremulant bouwden we al eens voor onze <Harmo>

robot.

- 18.06.2019: Resonatoren voor de noten 72 tot 77 gemaakt en gestemd. Materiaal:

grijs PVC , 32 mm diameter.

Bestelling geplaatst bij Demar-Lux voor aluminium buizen tot diameter 60 mm.

Buisdiameter 57 blijkt niet leverbaar, maar 55 mm klaarblijkelijk wel. Noten

54 tot 59 moeten dus opnieuw berekend worden.

Bestelling geplaatst bij Demar-Lux voor aluminium buizen tot diameter 60 mm.

Buisdiameter 57 blijkt niet leverbaar, maar 55 mm klaarblijkelijk wel. Noten

54 tot 59 moeten dus opnieuw berekend worden.

- 19.06.2019: Proefopstelling gemaakt met een buis waarvan we de ophanggaten

uitboorden tot 6 mm, zodat we er met zacht PVC beklede M3 draadstang kunnen

doorsteken. Het vergroten van de ophanggaten heeft geen door ons meetbare

invloed op de stemming. We hebben de indruk dat de toonhoogte minder dan een

cent daalt. Deze wijze van ophanging geeft evenwel, bij gelijke aanslagsterkte,

slechts ongeveer de helft van de geluidsterkte op.

- 20.06.2019: Aluminium buis 55/5 blijkt nu toch niet leverbaar te zijn...

Dan maar 60/5 voor het laagste oktaaf?

- 22.06.2019: Verdere proeven en berekeningen voor de konstruktie van de ophanging

van de buizen.

- 24.06.2019: De bij Laukhuff bestelde bidirektionele sleeplademagneten kunnen

bij dit bedrijf alleen nog besteld worden met een aangebouwde microprocessor

bestuurde regeling. Dit is voor onze toepassing evenwel volkomen onbruikbaar.

Bovendien staan die magneten met die schakeling nu ca. 250 euro per stuk geprijsd,wat

de kost met 6250 euro zou verhogen... Op zoek naar alternatieven. In de Kendrion

Kuhnke katalogus staan enkele types die in aanmerking kunnen komen: HD82-86R

F24. Het bidirektionele type UV40F heeft evenwel een trajekt van maximaal

8 mm, wat zeker met de M5 schroefdraad op het anker, aan de kleine kant is

voor onze toepassing. Het type V45 heeft een trajekt van 15 mm en is voorzien

van M6 schroefdraad op het anker. Hier is een link

naar de katalogus.

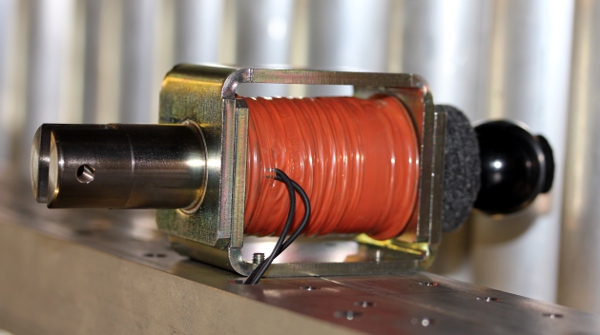

- 03.07.2019: Twaalf Kuhnke magneten (HD8286RF24) besteld bij Distrelek. Te

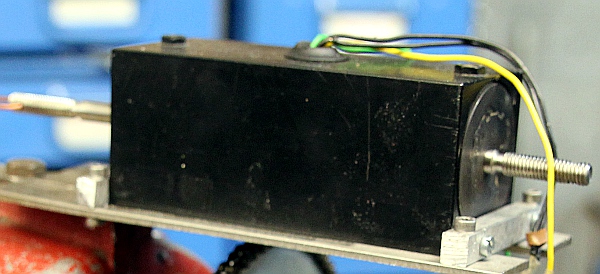

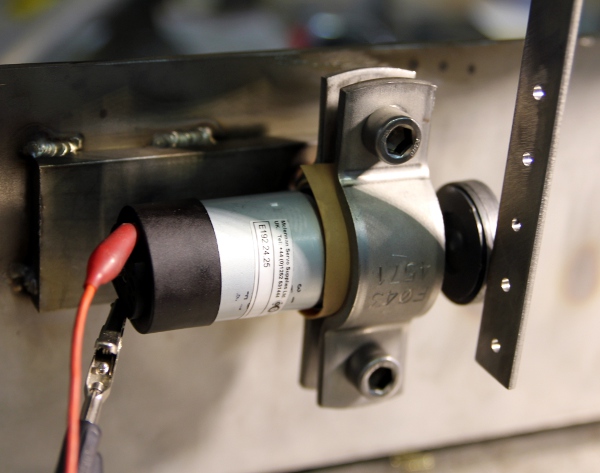

testen voor het onderste oktaaf. Hier is een foto van zo'n elektromagneet:

- 04.07.2019: Banggood: magneten besteld in China (12V, 1.5 Ohm). Elf Kuhnke

magneten werden geleverd, een magneet is in nabestelling.

- 05.07.2019: Levering Demar-Lux: Alu-buis diameters 55 en 60 mm. Buizen voor

de noten 54 tot 59 berekend, gezaagd en gestemd.

55mm / 45mm tube: (2.200 kg/m)

| midi note |

frequency (Hz) |

length (mm) |

suspension |

m constant |

weigth kg |

| 54 |

184 |

1298 |

291 |

1.1045 |

|

| 55 |

195 |

1261 |

283 |

1.1044 |

|

| 56 |

207.6 |

1225 |

274.5 |

1.1033 |

|

| 57 |

220 |

1190 |

267 |

1.104 |

|

| 58 |

233.1 |

1156 |

259 |

1.1037 |

|

| 59 |

246.9 |

1123 |

252 |

1.1036 |

|

- 06.07.2019: Berekenen, zagen en stemmen van de 60 mm aluminium buizen voor

de noten 48 tot 53.

60mm / 50mm tube: (2.331 kg/m)

| midi note |

frequency (Hz) |

length (mm) |

suspension |

m constant |

weigth kg |

| 48 |

130.8 |

1627.5 |

365 |

1.1172 |

|

| 49 |

138.6 |

1581 |

354.5 |

1.1169 |

|

| 50 |

146.8 |

1536 |

344 |

1.1169 |

|

| 51 |

155.6 |

1491 |

334 |

1.115 |

|

| 52 |

164.8 |

1449 |

325 |

1.1157 |

|

| 53 |

174.6 |

1407 |

315.5 |

1.1145 |

|

Absolute measurement error on lengths: +/- 0.5 mm.

Voor de laagste 12 noten (48 to 59) gebruiken we beter 1/4 lambda resonatoren

omdat anders het instrument hoger zou worden dan twee meter, wat niet alleem

problemen geeft bij transporten, maar ook de konstruktie van het vibrato mechanisme

ernstig bemoeilijkt. De organisatie van de buizen in de robot zou ideaal zijn

met 18 klankbuizen vooraan (breedte 1200 mm, wanneer we 10 mm tussenruimte

kunnen aanhouden) en 27 klankbuizen achteraan (wat met dezelfde tussenruimte

ook 1200 mm oplevert). De tessituur kan dan lopen van 48 tot en met 94. Dit

zou een goede dimensionering kunnen zijn voor de voorste rij:  Hier

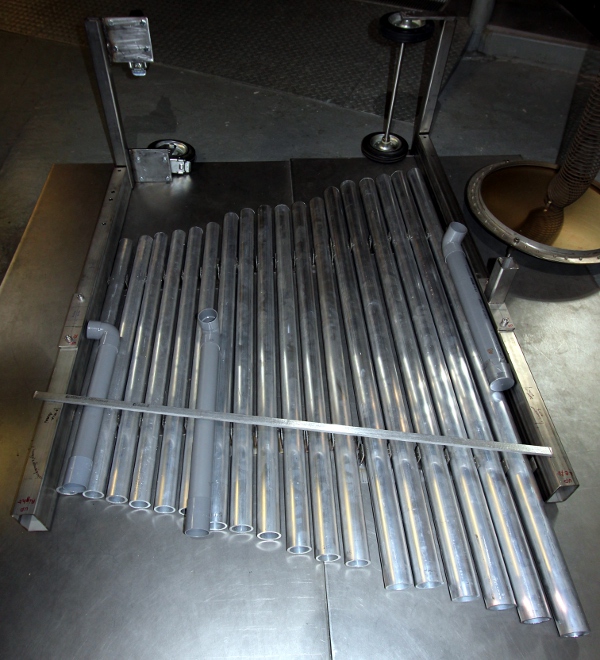

zijn we met de 12 gestemde buizen voor het laagste oktaaf:

Hier

zijn we met de 12 gestemde buizen voor het laagste oktaaf:

- 07.07.2019: Redaktie van een software programma voor de berekening van de

maatvoering voor de bouw van <Tubo>. Dit is het resultaat voor de eerste

module:

De breedte

van deze module komt dan uit op 430 mm. Ook de precieze maatvoering voor de

vertikale plaatjes, kunnen we heel exakt bepalen nu:

De breedte

van deze module komt dan uit op 430 mm. Ook de precieze maatvoering voor de

vertikale plaatjes, kunnen we heel exakt bepalen nu:  De vertikale plaatjes moeten in tweevoud gemaakt worden (het tweede exemplaar,

gespiegeld), want we hangen de buizen op twee nodale punten op. Alle maten

zijn opgegeven in mm.

De vertikale plaatjes moeten in tweevoud gemaakt worden (het tweede exemplaar,

gespiegeld), want we hangen de buizen op twee nodale punten op. Alle maten

zijn opgegeven in mm.

- 08.07.2019: Gespiegelde ophangplaatjes toegevoegd aan de werktekening. Belangrijk:

eerst alle gaatjes in de plaatjes boren alvorens ze vast te lassen op de achterplaat.

Eens gelast is boren en uitboren immers onmogelijk geworden vanwege de kleine

tussenruimte.

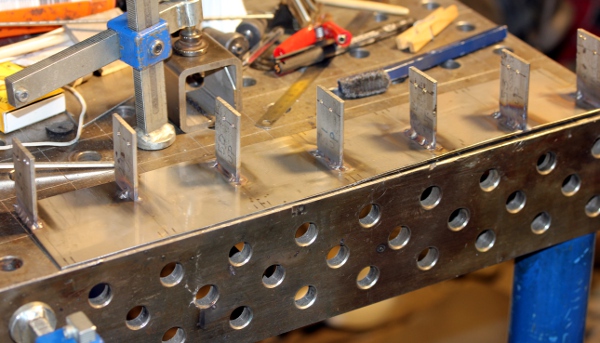

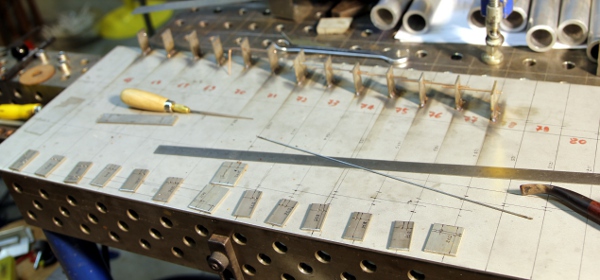

- 09.07.2019: Uitzagen en boren van de ophangbeugels uit 3 mm dik plat inox,

30 mm breed. Werktekening aangepast:

- 10.07.2019: Testresonator gemaakt in T vorm. Dit zou een groter geluidsvolume

moeten opleveren, maar het bemoeilijkt wel de konstruktie van het vibrato

mechanisme. Uitsnijden twee achterplaten voor de beugels (430 x 80 x 2). TIG-laswerk

bovenste en onderste houder voor noten 48 tot 53.

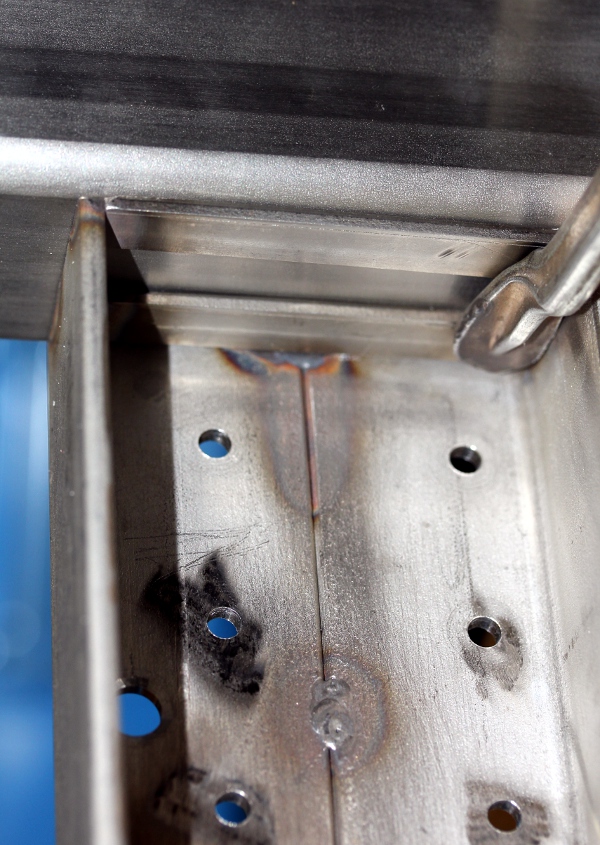

Volledig

rondlassen van de uitstekende ophangstukken blijkt onmogelijk vanwege de ruimte

die we voor de TIG toorts en haar beweging zelf nodig hebben. Hier is een

foto van de beide afgelaste beugels:

Volledig

rondlassen van de uitstekende ophangstukken blijkt onmogelijk vanwege de ruimte

die we voor de TIG toorts en haar beweging zelf nodig hebben. Hier is een

foto van de beide afgelaste beugels:  Het ziet ernaar uit dat we met veel moeite de hoogte van dit instrument kunnen

beperken tot twee meter.

Het ziet ernaar uit dat we met veel moeite de hoogte van dit instrument kunnen

beperken tot twee meter.

- 11.07.2019: Werkplan voor de tweede module:

Ophangplaatjes,

inox plat 30 mm x 3 mm x 45 mm gezaagd en geboord. Alle plaatjes gelast. Hele

dag werk...

Ophangplaatjes,

inox plat 30 mm x 3 mm x 45 mm gezaagd en geboord. Alle plaatjes gelast. Hele

dag werk...

- 12.07.2019: Werktekening voor module 3:

Voor de ophangplaatjes kunnen we inox plat 30 x 3 aanhouden. We kunnen hier

alle plaatjes afzagen op 40 mm. Uitzagen en boren van de gaatjes.

Voor de ophangplaatjes kunnen we inox plat 30 x 3 aanhouden. We kunnen hier

alle plaatjes afzagen op 40 mm. Uitzagen en boren van de gaatjes.

- 13.07.2019: TIG-laswerk voor de ophangbeugels van module 3, noten 60 tot

65. Mogelijke samenvoeging van de eerste drie modules:

Om de vertikale verbindingen te maken, zou dit een mogelijkheid zijn, gebruik

makend van inox plat 10 x 20:

Om de vertikale verbindingen te maken, zou dit een mogelijkheid zijn, gebruik

makend van inox plat 10 x 20:  De

aanslagsolenoids zijn in de lengte niet helemaal op schaal getekend. De opgegeven

lengte maat, 180 mm, is de volledige ruimte die de solenoiden in beslag nemen.

De horizontale drager waarop ze gemonteerd moeten worden, moet losneembaar

zijn. (Vier lange M10 bouten gebruiken). Anders is het onmogelijk de klankstaven

in de struktuur op te hangen. Een maatschets voor de frontale kant zou er

zo kunnen uitzien:

De

aanslagsolenoids zijn in de lengte niet helemaal op schaal getekend. De opgegeven

lengte maat, 180 mm, is de volledige ruimte die de solenoiden in beslag nemen.

De horizontale drager waarop ze gemonteerd moeten worden, moet losneembaar

zijn. (Vier lange M10 bouten gebruiken). Anders is het onmogelijk de klankstaven

in de struktuur op te hangen. Een maatschets voor de frontale kant zou er

zo kunnen uitzien:  Aan de rechterkant komt plaats vrij voor de inbouw van de elektronika en de

aansluitingen voor voeding en data.

Aan de rechterkant komt plaats vrij voor de inbouw van de elektronika en de

aansluitingen voor voeding en data.

- 14.07.2019: Ontwerp van een geschikte wielbasis, met zo mogelijk beperking

van de diepte van de robot tot 450 mm. Berekening van de lengtes van de vertikale

opstanden, wanneer we die zouden vervaardigen uit 100 x 50 x 3 inox kokerprofiel.

Hier is een eerste tentatief ontwerp:

De wielen aan de rechterkant zijn zwenkwielen, bouwhoogte 125 mm, wieldiameter

100 mm. Grotere wieldiameters zijn ook mogelijk, aangezien de wielen de dempers

niet in de weg zitten. De maximale diameter, zonder de totale bouwhoogte te

vergroten zou 250 mm zijn. Die wielen hebben we echter niet op voorraad.

De wielen aan de rechterkant zijn zwenkwielen, bouwhoogte 125 mm, wieldiameter

100 mm. Grotere wieldiameters zijn ook mogelijk, aangezien de wielen de dempers

niet in de weg zitten. De maximale diameter, zonder de totale bouwhoogte te

vergroten zou 250 mm zijn. Die wielen hebben we echter niet op voorraad.

- 15.07.2019: Plan opnieuw getekend indien we 200 mm wielen zouden gebruiken.

Wicke wielen 200x50, bouwhoogte 235, as 20mm, naaf 60mm. Deze wielen kosten

echter wel ca. 400 euro.

Vier

zwenkwielen met rem zouden natuurljk de handigste oplossing zijn. Om de kostprijs

te beperken kunnen we natuurlijk ook standaardzwenkwielen met zwarte rubberbanden

voorzien, ze kosten minder dan half zoveel als de mooiere Wicke wielen. Deze

standaard-wielen hebben een bouwhoogte van 243 mm. Het bouwplan zou er dan

komen uit te zien alsvolgt:

Vier

zwenkwielen met rem zouden natuurljk de handigste oplossing zijn. Om de kostprijs

te beperken kunnen we natuurlijk ook standaardzwenkwielen met zwarte rubberbanden

voorzien, ze kosten minder dan half zoveel als de mooiere Wicke wielen. Deze

standaard-wielen hebben een bouwhoogte van 243 mm. Het bouwplan zou er dan

komen uit te zien alsvolgt:  Voor

de lage kant, kunnen bij deze bouwhoogte echter geen zwenkwielen worden gebruikt:

ze komen in botsing met de onderste drie demper-magneten! Voor de noten 66

tot 71 kunnen we Kuhnke magneten, type HD6286-RF gebruiken. Die kosten 96

Euro per stuk bij Distrelec. De klankbuizen hebben hier een diameter van 40

mm.

Voor

de lage kant, kunnen bij deze bouwhoogte echter geen zwenkwielen worden gebruikt:

ze komen in botsing met de onderste drie demper-magneten! Voor de noten 66

tot 71 kunnen we Kuhnke magneten, type HD6286-RF gebruiken. Die kosten 96

Euro per stuk bij Distrelec. De klankbuizen hebben hier een diameter van 40

mm.

- 16.07.2019: Inkoop bokwielen, 200 mm diameter. Zes extra Kuhnke magneten

besteld bij Distrelec.

- 17.07.2019: Bokwiel sektie ontwerp gewijzigd (plan 13):

Gedetailleerd bouwplan voor de bokwielkonstruktie op een doorlopende as van

20 mm uitgetekend( plan 14):

Gedetailleerd bouwplan voor de bokwielkonstruktie op een doorlopende as van

20 mm uitgetekend( plan 14):  De

stelringen worden vastgezet met M6 stelbouten (inbus hex). Op die wijze zijn

de wielen eenvoudig af te nemen en indien nodig te vervangen. Uitzagen van

de 10 mm dikke wielhouders: 200 x 50 x 10 en precies boren van de 20 mm asgaten.

Bij nader toezicht, blijken de buitenste stelringen eigenlijk overbodig te

zijn.

De

stelringen worden vastgezet met M6 stelbouten (inbus hex). Op die wijze zijn

de wielen eenvoudig af te nemen en indien nodig te vervangen. Uitzagen van

de 10 mm dikke wielhouders: 200 x 50 x 10 en precies boren van de 20 mm asgaten.

Bij nader toezicht, blijken de buitenste stelringen eigenlijk overbodig te

zijn.

- 31.07.2019: Inkoop 60 mm PVC buis (regenafvoer) bij Deschacht. Ook 12 bochten

aangekocht. Stoppen voor deze buizen blijken niet te bestaan. In de katalogus

van Eriks zijn ze wel opgenomen, maar dan voor buisdiameter 63 mm.

- 17.08.2019: Atelier werk aan Tubo opnieuw gestart. Uitzagen en aftekenen

op werkstuk van de linker vertikale opstand. Materiaal: inox kokerprofiel

100 x 50 x 5. Hoogte 1524 mm. Positionering van de beaters:

- 18.08.2019: Uittekenen gedetailleerd bouwplan en te lassen onderdelen. Hier

is de konstruktietekening voor de kloppers met de Kuhnke elektromagneten:

- Alle onderdelen worden vervaardigd uit roestvast staal.

- 19.08.2019: Berekening en uitzagen van de rechterkolom: 100x50x3x1348. De

bouwhoogte van de zwenkwielen met rem is 242 mm. Montageplaten voor de zwenkwielen

uitgezaagd in 10 mm dik inox plaat, geboord en gelast op 600 mm kokerprofiel

50 x 50 x 5. Tegenlas uitgevoerd in TIG, om de krimp en de doorbuiging tegen

te gaan. De wielen worden bevestigd met M10 inox bouten. Om een indruk te

krijgen van de omvang en de verhoudingen van de robot in opbouw, legden we

de al gezaagde vrije onderdelen eens losjes uit:

- 20.08.2019: Uitsnijden en lassen van de linkerwieldrager. Kokerprofiel 50x50x5x552.

De as is massief inox, 20 mm diameter. Asgaten gehoond. Gaten geboord in de

vertikale opstanden: montage van de resonatoren en van de achterrij buizen

moet zo mogelijk worden. Deze delen moeten demonteerbaar zijn. Hadden we maar

een lastafel van 2 meter... In te kopen: inox cilinderbouten M10 x 20 voor

de montage van de zwenkwielen. Hier zijn de wielmontages, in opbouw:

En nu, het precies

uitmeten en aanlassen van de dragers voor de klankbuizen aan de voorkant van

de robot:

En nu, het precies

uitmeten en aanlassen van de dragers voor de klankbuizen aan de voorkant van

de robot:

- 21.08.2019: Lassen op de lastafel van de beide buisdragers op 20 x 10 warmgewalst

inox staafmateriaal. Passen van de klankbuizen op de dragers: met de buis

voor noot 55 is er een probleem, de geboorde gaten kloppen niet... Rekenfout

of meetfout. De gaatjes voor noot 65 moeten een beetje bijgevijld worden.

Lassen van de rechter

vertikale kolom op de zwenkwielhouder.

Lassen van de rechter

vertikale kolom op de zwenkwielhouder.

- 22.08.2019: Rechten van de kromgetrokken buishouders: tegenlas en plooipomp.

Elektrodelassen van de linkervertikale kolom op de wielbasis. Terugplaatsen

van de takels in het atelier, het werkstuk is inmiddels immers veel te zwaar

geworden om nog volledig manueel gemanipuleerd te worden...

- 23.08.2019: Pijpdrager aangelast aan de vertikale opnstanden. Dwarsversterking

zal nodig zijn. Hier en daar moeten boorgaatjes in de klankbuizen toch wat

worden bijgevijld. Meetfouten en kromtrekken van laswerk spelen ons duidelijk

parten.

- 24.08.2019: Dwarsversterkingsprofiel afgetekend: 100 x 50 x 3 x 1271. Kan

dienstig zijn voor de montage van de elektronika. Begin berekening van de

achterzijde...een tessituur tot en met midi noot 91 moet haalbaar zijn.

- 26.08.2019: Te warm in het atelier voor laswerk... tekenen dan maar.

- 27.08.2019: Ontwerpen en uittekenen van de dempermechanieken. De chinese

elektromagneten zijn voorzien van een (slordig gemaakte...) M5 schroefdraad.

Uitzagen van de demperplaatjes. Testmontage met vilten dempers. De elektromagneten

moeten met M4 trillingsdempers gemonteerd worden. Fivistop 60IRHD M4x10 MF

besteld bij Farnell: bouwhoogte 8 mm, diameter 10 mm. Plaatjes, diameter 60

mm uitgezaagd uit aluminiumplaat:

Hoe we de nodige viltringen netjes kunnen maken is nog niet geheel duidelijk.

Met een schaar ziet het er echt niet uit. Een holpijp voor de nodige maten

kost meer dan 150 euro... Morgen, een experiment met een laser-snijmachine...

Plaatjes diameter 55 mm (aluminium) en 50 mm (inox) uitgezaagd.

Hoe we de nodige viltringen netjes kunnen maken is nog niet geheel duidelijk.

Met een schaar ziet het er echt niet uit. Een holpijp voor de nodige maten

kost meer dan 150 euro... Morgen, een experiment met een laser-snijmachine...

Plaatjes diameter 55 mm (aluminium) en 50 mm (inox) uitgezaagd.

- 28.08.2019: Zuiver centeren van de plaatjes op de draaibank. Afslijpen van

de zaagbramen. Het experiment met een laser-cutter werkt bevredigend met vilt,

maar het snijden laat wel een bruine rand na op het vilt. Uitzagen van de

houder voor de dempermagneten uit geplooid inox (dikte 2 mm). Voor het boren

van de gaten voor de magneten moeten we eerst een precieze boormal maken.

Het uitlijnen ervan belooft bijzonder moeilijk te worden, Hier is een afgewerkt

exemplaar van een demper-eenheid:

Alleen de trajektbegrenzingsviltring, tevens terugslagdemper, ontbreekt nog.

Alleen de trajektbegrenzingsviltring, tevens terugslagdemper, ontbreekt nog.

- 29.08.2019: Alle dempermagneten voorzien van trillingdempers. Test-presentatie

van de gemonteerde dempers op het chassis. Vastmaken chassis op de draagstruktuur.

Trajektbegrenzingsviltschijven besteld. Deze worden in de handel gebracht

voor de montage van hihat cymbalen. De dikte is 15 mm, diameter 40 mm.

Trajektbegrenzingsviltschijven besteld. Deze worden in de handel gebracht

voor de montage van hihat cymbalen. De dikte is 15 mm, diameter 40 mm.

- 30.08.2019: Om de magneten goed te kunnen afstellen, hebben we eigenlijk

een metaalfrees nodig die ons zou toelaten sleuven te maken in de inox draagplaten...

Viltschijven voor de dempers gelaserd en afgeleverd. Vastkleven van deze viltschijven

op de ronde metalen plaatjes. Hiervoor gebruikten we transparante siliconenrubber.

Uithardingstijd: 24u. De demperspoelen trekken bij 12V een stroom van 8 ampere.

De duty cycle moet volgens opgave van de fabrikant beperkt blijven tot 5%.

De voeding moet dit in pulsbedrijf kunnen leveren voor minstens 4 spoelen

tegelijkertijd. De piekstroom wordt dan 32 A... Wanneer we het gewicht van

de transformator binnen de perken willen houden, zijn we aangewezen op het

toepassen van heel erg grote elko's. Dat recept pasten we eerder al toe in

onze <Puff> robot.

- 31.08.2019: Testmontage van vier demperspoelen of het hoofdchassis. Het

precies boren van de gaatjes belooft een werk van lange adem te worden. De

eerste zes magneten worden met telkens vier rondellen (dikte 2 mm, Ettinger,

Farnell order nr. 1466917) ) gemonteerd met M4x10 cilinderboutjes.

- 01.08.2019: Verder aftekenen van de boorgaten voor de dempers en boren van

de gaten. Uitzagen van de twee kokerprofielen 50x50x5x220 waaraan de kloppers

zullen worden bevestigd. Het lassen op de 10 mm dikke montageplaten moet even

wachten wegens gebrek aan ruimte op de lasttafel. Na een hele dag werken,

hebben we nu al 13 dempers uitgelijnd en gemonteerd. De voorraad M4x10 boutjes

is nu uitgeput.

- 02.09.2019: Boren van de gaatjes voor de laatste vijf dempers aan de voorkant.

Bestelling bouten en montagemateriaal bij Fabory. Uittekenen mogelijke bedrading

en gebruik van een konnektor zodat de demperlat eenvoudig losneembaar zou

zijn. We kunnen eventueel hetzelfde type 30-polige konnector gebruiken als

eerder toegepast in <Hybr>. Alvast 6 dikke aluminium schijfjes uitgezaagd

voor de 40 mm diameter klankbuizen aan de achterzijde.

- 03.09.2019: Demperdrager terug helemaal losgenomen om de gaten voor de doorvoer

van de aansluitdraden te kunnen boren. Meteen ook alle boorgaten voor de spoelmontage

ontbraamd. Begin werktekeningen voor de achterzijde, buisophanging. Inox L-profiel

40x40x4 besteld bij Demar-Lux. Aluminium plaatjes voor de dempers aan de 35

mm klankbuizen uitgezaagd.

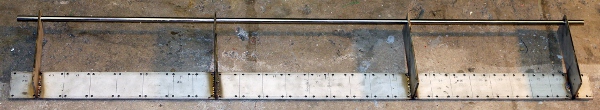

- 04.09.2019: Maatplan achterzijde uitgewerkt in 1 dimensie:

Te

zagen onderdelen: 4 plaatjes 30x40x3, 50 plaatjes 20x40x3. Montageplaten:

1272 x140 x 4.

Te

zagen onderdelen: 4 plaatjes 30x40x3, 50 plaatjes 20x40x3. Montageplaten:

1272 x140 x 4.

- 05.09.2019: Aftekenen van het volledige bouw- en lasplan op de grote 3 mm

dikke achterplaat. De afstanden van nodaal punt tot aanslaglijn werden berekend

en in vertikale getallen op het werkplan aangebracht. Holpijpen besteld bij

Decoene voor de aanmaak van de dempervilten.

- 06.09.2019: De cymbaalviltringen werden geleverd. We kunnen ze, met een

dun laagje siliconenrubber op de dempermagneten bevestigen. De twee 50x50x520

kokerprofielen vastgelast op de 10 mm dikke onderplaten voor de slagmagneten.

- 07.09.2019: Konstruktie van de drager voor de slagmagneten volgens bouwtekening

17. Aftekenen en boren van alle 72 bevestigingsgaten. Om wat speling te

hebben zijn al deze gaten op 5 mm geboord. Doorvoergaten eveneens geboord

en aan beide kanten gefreesd om beschadiging van de elektrische bedrading

te vermijden. De sleuven voor de afregeling van de slagmagneten werd uitgevoerd

met stukjes 10x3x72, ingelast op de zijkanten:

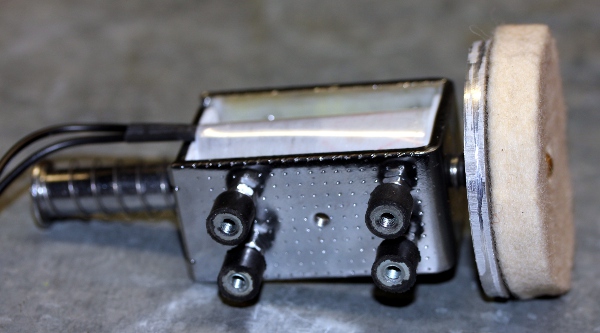

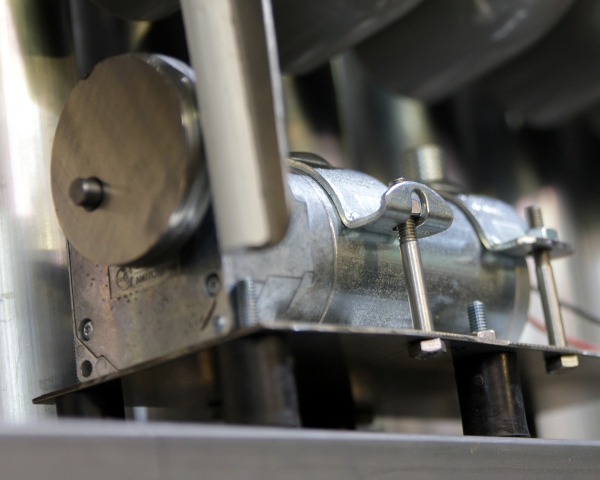

Testmontage van enkele van de Kuhnke magneten, voorzien van een terugslagdempingsviltring

en bakeliet klopper:

Testmontage van enkele van de Kuhnke magneten, voorzien van een terugslagdempingsviltring

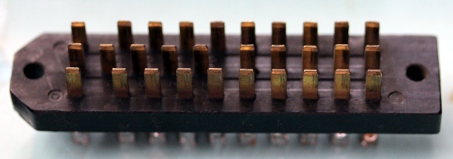

en bakeliet klopper:  Op de bakeliet kogelknop is hier een viltje aangebracht, maar dat moeten uiteindelijk

dikke stukjes zacht leder worden. Alvast montagegaten geboord voor de plaatsing

van een 30-polige konnektor met meskontakten. Een LED-strip kan eventueel

aan de onderkant over de gehele lengte worden aangebracht.

Op de bakeliet kogelknop is hier een viltje aangebracht, maar dat moeten uiteindelijk

dikke stukjes zacht leder worden. Alvast montagegaten geboord voor de plaatsing

van een 30-polige konnektor met meskontakten. Een LED-strip kan eventueel

aan de onderkant over de gehele lengte worden aangebracht.

- 08.09.2019: Soldeerlippen strips gemonteerd aan de binnenzijde van de drager

voor de klopmagneten. Bevestiging op isolatieplaatje met M10 x 3 boutjes.

De slageenheid kan nu gemonteerd worden en vormt een zelfstandig en demonteerbaar

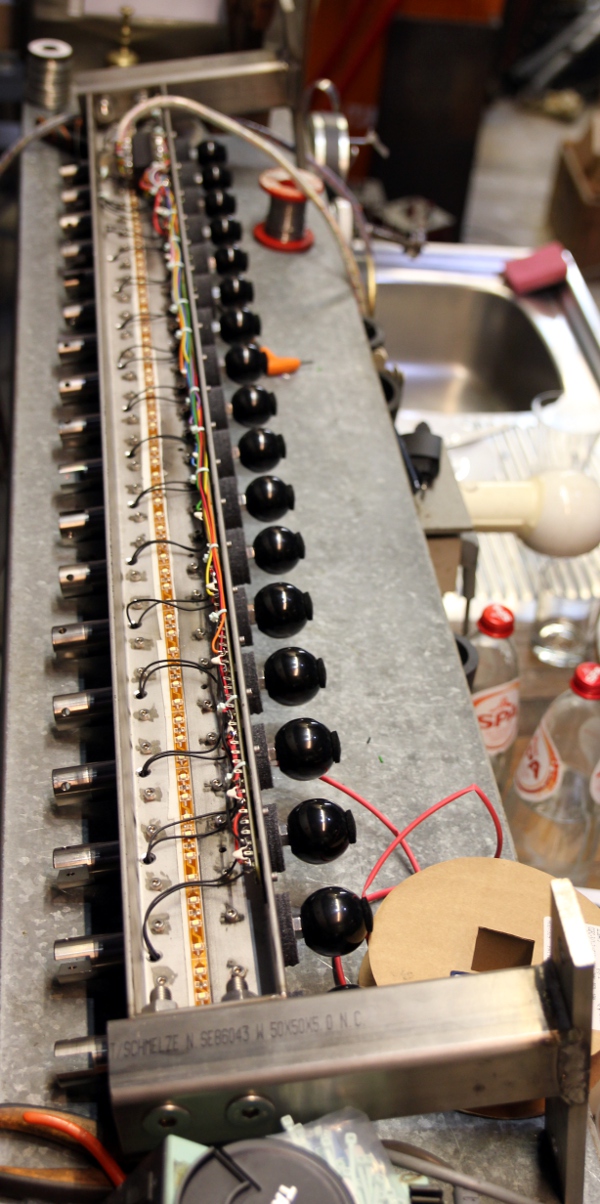

geheel. Hier een zicht op het eerste begin van de opbouw:

De

aanslagkogels in bakeliet en voorzien van een M8 schroefdraad hebben per zes

klankbuizen een verschillende aflopende maat: 40mm, 36mm, 32mm, 25mm.

De

aanslagkogels in bakeliet en voorzien van een M8 schroefdraad hebben per zes

klankbuizen een verschillende aflopende maat: 40mm, 36mm, 32mm, 25mm.

- 09.09.2019: Boren van de zijdelingse bevestigingsbouten voor de sleuven

van de klopmagneten eenheid: Verzonken M12 x 80 bouten, vier stuks. De gaten

werden geboord en nagehoond op exakt 12 mm. Bij de eindmontage van deze unit

bleken 3 van de 18 schroefdraden (M8) op de Kuhnke magneten beschadigd of

toch minstens onnauwkeurig gedraaid. Deze hebben we opnieuw getapt. Alle kogels

voorzien van 2.5 mm dikke zelfklevende viltjes. Demper terugslagvilten vastgekleefd

op de Banggood magneten met siliconenrubber.

De stalen trappen in het Logos atelier zijn wel erg handig hiervoor... Alle

magneten terug losgenomen om de nog niet geboorde montagegaten te kunnen boren

evenals de 6mm doorvoergaten voor de aansluitdraden.

De stalen trappen in het Logos atelier zijn wel erg handig hiervoor... Alle

magneten terug losgenomen om de nog niet geboorde montagegaten te kunnen boren

evenals de 6mm doorvoergaten voor de aansluitdraden.

- 10.09.2019: De klopper eenheid is nu ook voorzien van de witte LED-strip:

Ontwerp van mogelijke

besturingsschakelingen voor de dempermagneten. Puls en hold schakelingen zoals

toegepast in talloze vroegere robots zoals de player-piano zijn mogelijk maar

vergen een groot aantal onderdelen en stellen ook nogal wat eisen aan de firmware

vanwege het oplopend aantal nodige timers. Daarom experimenteerden we wat

met een oeroud recept: het gebruik van gloeilampen als spanningsafhankelijke

weerstanden. Dit pasten we al in 1989 toe in onze <Autosax> robot. Gezien

de grote stroom nodig voor de bekrachtiging van de Banggood spoelen (1.5 Ohm

weerstand bij 12V levert 8A op...), gebruikten we voor onze metingen een zware

12V loodakku als spanningsbron. Hierbij schema en resultaat van de berekening

en de metingen:

Ontwerp van mogelijke

besturingsschakelingen voor de dempermagneten. Puls en hold schakelingen zoals

toegepast in talloze vroegere robots zoals de player-piano zijn mogelijk maar

vergen een groot aantal onderdelen en stellen ook nogal wat eisen aan de firmware

vanwege het oplopend aantal nodige timers. Daarom experimenteerden we wat

met een oeroud recept: het gebruik van gloeilampen als spanningsafhankelijke

weerstanden. Dit pasten we al in 1989 toe in onze <Autosax> robot. Gezien

de grote stroom nodig voor de bekrachtiging van de Banggood spoelen (1.5 Ohm

weerstand bij 12V levert 8A op...), gebruikten we voor onze metingen een zware

12V loodakku als spanningsbron. Hierbij schema en resultaat van de berekening

en de metingen:  Om

de responssnelheid niet nog meer te vertragen dan nodig, gebruikten we hier

geen terugslagdiodes maar wel een stevige MOV van Epcos. Voor de MOSFET kan

ook een IRL640 worden toegepast, maar die dissipeert dan wel 1.5W (Rds_on

= 0.18 Ohm). Voor de IRF3710, met een Rds_on van 18 milliohm, zakt de dissipatie

in de MOSFET tot 154mW. Dit type heeft echter een wat hogere gate spanning

nodig. IRLZ44 of IRLZ34 zijn wat dat betreft betere keuzes. Voor de aansturing

van alle 18 dempermagneten kunnen we nu met een enkele PIC-controller volstaan,

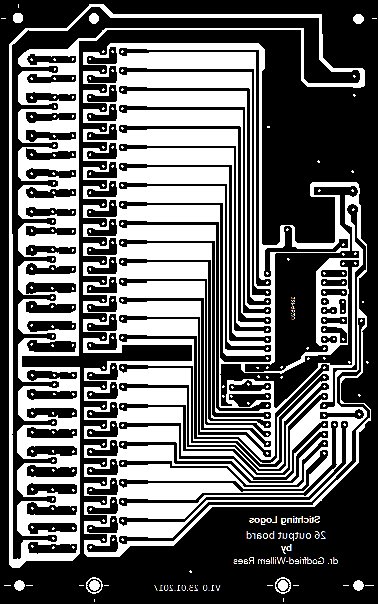

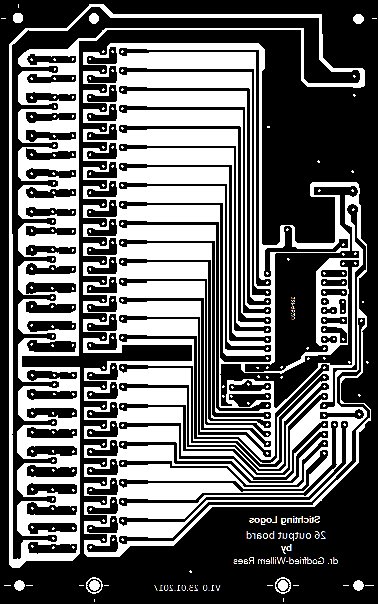

wanneer we een 18F4620 type nemen. Een mogelijk toepasbaar PCB is dit ontwerp

voor een 26-output board, V1.0 23.01.2017:

Om

de responssnelheid niet nog meer te vertragen dan nodig, gebruikten we hier

geen terugslagdiodes maar wel een stevige MOV van Epcos. Voor de MOSFET kan

ook een IRL640 worden toegepast, maar die dissipeert dan wel 1.5W (Rds_on

= 0.18 Ohm). Voor de IRF3710, met een Rds_on van 18 milliohm, zakt de dissipatie

in de MOSFET tot 154mW. Dit type heeft echter een wat hogere gate spanning

nodig. IRLZ44 of IRLZ34 zijn wat dat betreft betere keuzes. Voor de aansturing

van alle 18 dempermagneten kunnen we nu met een enkele PIC-controller volstaan,

wanneer we een 18F4620 type nemen. Een mogelijk toepasbaar PCB is dit ontwerp

voor een 26-output board, V1.0 23.01.2017: Een eerste schets van de firmware meteen uitgewerkt. De voeding zou er kunnen

uitzien als:

Een eerste schets van de firmware meteen uitgewerkt. De voeding zou er kunnen

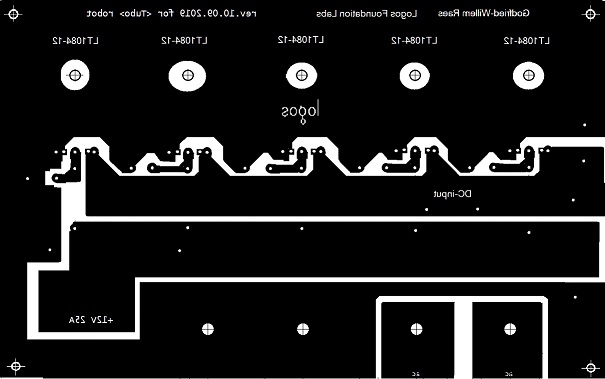

uitzien als:  Met

zo'n ontwerp kunnen maximaal vijf dempers tegelijkertijd geaktiveerd worden.

In de houd-faze is de polifonie beperkt tot tien dempers. Deze beperking heeft

alleen betrekking op het laagste anderhalf oktaaf. De LT1084-12 regulators

zijn niet langer verkrijgbaar bij Farnell, wel nog bij RS-Components. Voor

het PCB kunnen we nagenoeg hetzelfde ontwerp gebruiken als voor <Zi>,

uit 2015. De 12V / 300W transformator (Erea) kunnen we recycleren uit een

vroegere versie van de voeding gebouwd voor <Flex>. Het afgewerkte dempermechanisme,

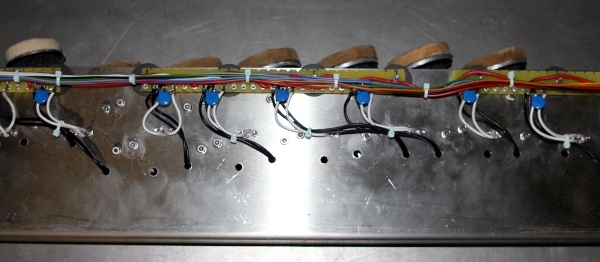

voorzien van alle dempingsvilten ziet er nu uit als:

Met

zo'n ontwerp kunnen maximaal vijf dempers tegelijkertijd geaktiveerd worden.

In de houd-faze is de polifonie beperkt tot tien dempers. Deze beperking heeft

alleen betrekking op het laagste anderhalf oktaaf. De LT1084-12 regulators

zijn niet langer verkrijgbaar bij Farnell, wel nog bij RS-Components. Voor

het PCB kunnen we nagenoeg hetzelfde ontwerp gebruiken als voor <Zi>,

uit 2015. De 12V / 300W transformator (Erea) kunnen we recycleren uit een

vroegere versie van de voeding gebouwd voor <Flex>. Het afgewerkte dempermechanisme,

voorzien van alle dempingsvilten ziet er nu uit als:  Voor de montage van de lampjes is het wachten op de levering van de gepaste

lampvoetjes door Conrad.

Voor de montage van de lampjes is het wachten op de levering van de gepaste

lampvoetjes door Conrad.

- 11.09.2019: Wachten op levering van lampvoeten (Conrad) , MOV's (Farnell)

, LT1084 regulatoren (RS components) .... Een leverancier voor op epoxy gemonteerde

soldeersteuntjes konden we nog niet vinden. Verbeteringen aangebracht aan

het PCB ontwerp voor de 12V-25A voeding, uitgaand van het <Zi> ontwerp.

Voor de bruggelijkrichter kunnen we vier 70HFLR20S02 diodes (70A/100V) gebruiken,

een klassieke 25A brug lijkt immers maar marginaal te volstaan hier.

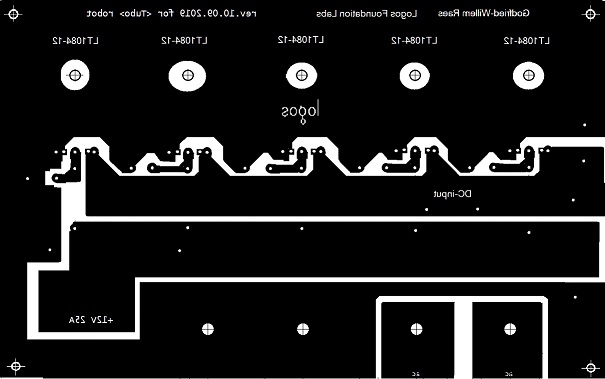

De

bufferelko kon geen plaats vinden op de printplaat en moet dus extern worden

aangesloten. Hier is het printontwerp:

De

bufferelko kon geen plaats vinden op de printplaat en moet dus extern worden

aangesloten. Hier is het printontwerp:  Film aangemaakt, belicht ontwikkeld, geetst en geboord, En, hier is een foto

van de bestukte print voor deze voeding:

Film aangemaakt, belicht ontwikkeld, geetst en geboord, En, hier is een foto

van de bestukte print voor deze voeding:  Alleen vijf 47uF kondensatoren onbreken nog op de print. Die zijn in bestelling...

Alleen vijf 47uF kondensatoren onbreken nog op de print. Die zijn in bestelling...

- 12.09.2019: Tests op de voeding voor de 12V dempers. Bedradingsfout in de

gelijkrichtdiodes gekorrigeerd. Voor de besturing van de kloppers zouden we

kunnen uitgaan van het ontwerp gemaakt voor de <Bello> robot. Die PCB's

besturen 1 oktaaf per board en note-repetition met keypressure is goed geimplementeerd

in de firmware. Levering van de Osram 12V/35W halogeenlampjes en de porceleinen

lampvoetjes. Montage- en draaddoorvoergaten geboord op de lage demperunit.

Alle lampjes gemonteerd (elk met twee M3x16 boutjes). Meteen ook gaatjes geboord

voor de draadsteunen van de bedrading. Voor de bedrading moeten we nog wachten

op een levering van Farnell.

- 13.09.2019: 300W - 12V Erea transformator losgemaakt uit de oude <Flex>

voeding. De nog ontbrekende 47uF elkos werden geleverd en meteen ingesoldeerd.

De 12V voeding blijkt perfekt te werken. Volledige montage van dempers en

lampjes afgewerkt. Begin montage van de klankbuizen op dik nylondraad met

tussenviltjes. Hiermee zijn we halfweg geraakt, mede dankzij de hulp van Bert

Vandekerckhove. Toroidale transformator 2 x 35V, 500VA opgedolven uit voorraad.

Ideaal geschikt voor de voeding van de kloppers.

- 14.09.2019: Ontwerp van het draagchassis voor de voedingen, de netspanningsingang,

de hoofdschakelaar en het midi-hub board. Hiervoor gebruiken we een ronde

plaat in aluminium, 20 mm dik. Bevestiging aan het chassis met twee M10 cilinder

bouten en twee M6 bouten, verzonken in het aluminium.

- 15.09.2019: Uittekenen en boren van de montagegaten voor de voedingskomponenten.

IEC netspanningsingangen (chassisdelen) besteld bij Farnell. Alle gaten geboord

en getapt met M3,M4, M5 en M6 schroefdraad, naar gelang de maten van de te

monteren onderdelen. Er is nu plaats voor de 12V-25A voeding, de 100V-6A voeding,

een extra 12V-12.5A SMPS voeding, het hub board met de 5V-2A voeding, de schakelaar

en de IEC ingang en twee MOSFET besturingsprinten voor de lage kant van de

robot. Hier een foto van de voorlopige plaatsing:

Aan

de onderzijde kunnen we nog een blauwe 12V LED spot voorzien.

Aan

de onderzijde kunnen we nog een blauwe 12V LED spot voorzien.

- 16.09.2019: Opruim atelier. Was stilaan dichtgeslibt geraakt. Verder werk

aan de firmware voor dempers en kloppers.

- 17.09.2019: IEC chassisdelen geleverd en gemonteerd. Zekering van 6A (traag)

geplaatst. Begin PCB ontwerp voor de 18 kloppers.

- 18.09.2019: Verdere afwerking van de ophanging van de klankbuizen voor de

noten 48 tot 65. Bedrading 30-polige konnektor op de kloppers.

De

meskontakten komen op het chassis te zitten, het vrouwelijk deel aan de samen

te stellen multikabel. Alle bedrading gesoldeerd, behalve de zwarte en rode

draden, wegens doorheen de voorraad. Enkele nieuwe haspels 0.5 mm2 draad besteld

bij Farnell. Hierbij het bedradingsplan:

De

meskontakten komen op het chassis te zitten, het vrouwelijk deel aan de samen

te stellen multikabel. Alle bedrading gesoldeerd, behalve de zwarte en rode

draden, wegens doorheen de voorraad. Enkele nieuwe haspels 0.5 mm2 draad besteld

bij Farnell. Hierbij het bedradingsplan:

- 19.09.2019: Wachten op levering draad door Farnell... Aangekomen, en meteen

bedrading volledig afgewerkt. VDR's (150V) gemonteerd parallel over de spoelen.

LED-strip vastgekleefd met dubbelzijdig plakband. Rechtstreeks kleven van

de LED strip was onmogelijk, vanwege niet geisoleerd aan de kleefzijde.

Demper unit terug

losgenomen en begin bedrading ervan. De VDR wordt vlakbij de spoelen gesoldeerd.

Hier is de tabel met de voor de dempers gebruikte draadkleuren:

Demper unit terug

losgenomen en begin bedrading ervan. De VDR wordt vlakbij de spoelen gesoldeerd.

Hier is de tabel met de voor de dempers gebruikte draadkleuren:

| 48 |

zwart |

| 49 |

bruin |

| 50 |

rood |

| 51 |

oranje |

| 52 |

geel |

| 53 |

groen |

| 54 |

blauw |

| 55 |

violet |

| 56 |

grijs |

| 57 |

wit |

| 58 |

zwart-wit |

| 59 |

zwart-roze |

| 60 |

zwart-rood |

|

61

|

zwart-oranje |

| 62 |

zwart-geel |

| 63 |

groen-blauw |

| 64 |

grijs-blauw |

| 65 |

rood-geel |

Alle bedrading uitgevoerd met 0.5 mm2 draad, behalve de gemeenschappelijke

positieve voedingsdraad, die op 1.5 mm2 werd genomen.

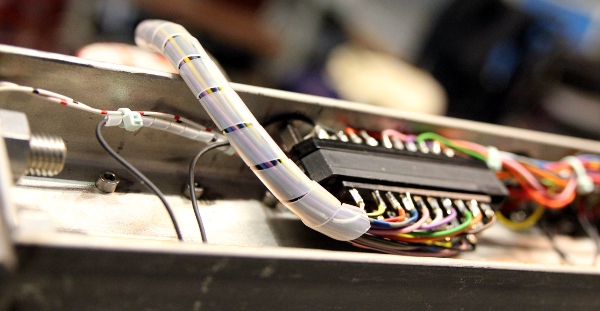

- 20.09.2019: Aanbrengen spirawrap rond de beide kabelbundels. Begin implementatie

van <Tubo> in GMT. Daarzonder kunnen we immers geen testkode maken.

Ikoontje aangemaakt en opgenomen in de resource files. Uitzagen van de dwarsverbindingsbalk

in inox 100x50x3 kokerprofiel. Begin bedrading van de voedingseenheid.

- 21.09.2019: De bestelde holpijpen nodig voor het maken van de vilten voor

de dempers voor de noten 66 tot 91 zijn aangekomen bij De Coene. Verder werk

aan de bedrading van de voedingseenheid voor de noten 48-65.

Hub

en 12V-SMPS doen het al. Ook de andere voedingen werken wanneer we het relais

overbruggen. Begin redaktie van de kode voor het midi-hub board in de Proton+

kompiler. Dit implementeert in eerste plaats een midi-filter en parser en

in tweede orde de besturing van de lampjes in het notenbereik 120-127. De

lampjes voor de noten 120,121 en 122 zijn al toegewezen en bedraad. De parser

introduceert wel een latency van 1 ms in de midi-flow. Hier is het dubbelzijdig

printontwerp:

Hub

en 12V-SMPS doen het al. Ook de andere voedingen werken wanneer we het relais

overbruggen. Begin redaktie van de kode voor het midi-hub board in de Proton+

kompiler. Dit implementeert in eerste plaats een midi-filter en parser en

in tweede orde de besturing van de lampjes in het notenbereik 120-127. De

lampjes voor de noten 120,121 en 122 zijn al toegewezen en bedraad. De parser

introduceert wel een latency van 1 ms in de midi-flow. Hier is het dubbelzijdig

printontwerp:  Hier is het schema van hub-schakeling:

Hier is het schema van hub-schakeling:

- 22.09.2019: Bestukking van het PCB voor de besturing van de dempers. Hier

gebruiken we slechts 18 van de 26 uitgangen. Dit board krijgt wel de grootste

stromen te verwerken. Voor de power MOSFETS kozen we hier uiteindelijk voor

het type IRLZ34NPBF in TO220 behuizing. Ug= 2V, Uds = 55V, Ids=30A#, Ron=0.035

Ohm. Hier is de datasheet. Merk op dat we op

dit board geen terugslagdiodes monteren, gezien de VDR's over de spoelen.

- 23.09.2019: Tubo helemaal geimplementeerd in GMT. De firmware voor de midi-hub

werkt naar behoren, die voor het demperboard krijgen we maar niet werkend...

- 24.09.2019: Problemen met de firmware voor het demperboard opgelost: de

compiler eist klaarblijkelijk de aanwezigheid van een HRSout instruktie in

de kode als voorwaarde om de midi-in interrupt te kunnen starten.... Versie

1.0 van de demper firmware flashed op het demperboard. De demp pulsduren zijn

nu regelbaar tussen 35ms en 250ms. De timing resolutie is ca. 10us nu. Wachten

op de levering van de ontbrekende IRLZ34 power mosfets...

- 25.09.2019: Afwerking ontwerp van een PCB voor het 4865 beaterboard. Hier

is de film:

(Schaal 200%) Belichten, ontwikkelen, etsen ,boren en solderen van alle nodige

komponenten... Meteen ook twee boards geetst met 26 outputs voor de beaters

en dempers voor de notes 66 tot 91. Deze PCB's zijn grotendeels gelijk aan

die voor het demperboard voor de noten48-65. De film is V1.1- 24.09.2019.

Narekenen van de parameters voor het laag beaterboard: De Kuhke magneten hebben

een weerstand van 36 Ohm (berekend vanuit P=16W bij U=24V, uit het datablad).

Bij 100V trekken ze dus een stroom van 2.76A. Die stroom loopt door de mosfet,

die (voor de IRL640) een Ron heeft van 0.18 Ohm. Derhalve is de dissipatie

in de Mosfet bij bekrachtigde spoel 1.38W. Gezien de duty cycle in normaal

bedrijf beperkt blijft tot 5%, zitten we dus zeker safe wat dat betreft. We

zouden er goed aan doen de duur van de bekrachtigingpulsen te beperken tot

10ms teneinde zeker binnen de safe operation area van de mosfets te blijven.

Alle komponenten op het laag beaterboard gesoldeerd en de processor meteen

van een eerste versie van de firmware voorzien. De terugslagdiodes op deze

print zijn MUR620C types.

(Schaal 200%) Belichten, ontwikkelen, etsen ,boren en solderen van alle nodige

komponenten... Meteen ook twee boards geetst met 26 outputs voor de beaters

en dempers voor de notes 66 tot 91. Deze PCB's zijn grotendeels gelijk aan

die voor het demperboard voor de noten48-65. De film is V1.1- 24.09.2019.

Narekenen van de parameters voor het laag beaterboard: De Kuhke magneten hebben

een weerstand van 36 Ohm (berekend vanuit P=16W bij U=24V, uit het datablad).

Bij 100V trekken ze dus een stroom van 2.76A. Die stroom loopt door de mosfet,

die (voor de IRL640) een Ron heeft van 0.18 Ohm. Derhalve is de dissipatie

in de Mosfet bij bekrachtigde spoel 1.38W. Gezien de duty cycle in normaal

bedrijf beperkt blijft tot 5%, zitten we dus zeker safe wat dat betreft. We

zouden er goed aan doen de duur van de bekrachtigingpulsen te beperken tot

10ms teneinde zeker binnen de safe operation area van de mosfets te blijven.

Alle komponenten op het laag beaterboard gesoldeerd en de processor meteen

van een eerste versie van de firmware voorzien. De terugslagdiodes op deze

print zijn MUR620C types.

- 26.09.2019: Montagegaten geboord voor de boards op de ronde voedingsplaat.

Verder werk aan de firmware voor de lage dempers. Een eerste beveiliging werd

ingevoerd zodat snel opeenvolgende note-offs niet de aan-tijd van de dempers

steeds maar verlengen. Een begrenzer van de polyfonie moet nog worden toegevoegd,

al zou dat ook te verwezenlijken zijn in de hardware. Nieuwe metingen van

de loopspeed en de pulsduren op het laag beaterboard na aanpassing van de

velo-scaling lookup: loopspeed 111kHz max, 102kHz min. Puls-duur bij velo=1:

30ms, bij velo=127: 150ms. Resolutie: 25us.

- 27.09.2019: Solderen van de twee PCB's voor de dempers en beaters in het

bereik 66-91.

- 28.09.2019: Verder werk aan de bedrading en de assemblage van de voedingsmodule.

Bedrading hub-board. Montage van de blauwe LED spots. De drie processor boards

werken nu en alle voedingsspanningen zijn korrekt bevonden. De module is klaar

voor inbouw in de Tubo robot.

- 29.09.2019: Eerste test waarbij de demper unit, afzonderlijk, wordt verbonden

met de voeding en de overeenkomstige microprocessor. De scaling moet duidelijk

nog worden aangepast en eventueel moeten we het trajekt van de ankers mechanisch

nog verder beperken. Wanneer we met zes demper tegelijkertijd aktief, de voedingsspanning

meten, zakt deze tot 10V. De ingangsspanning van de regulator -gemeten over

de 220mF elko- valt dan terug tot minder van 12V, waardoor de regulering natuurlijk

niet meer kan werken. Met 10 dempers tegelijkertijd aktief, worden ge gelijkrichters

warm. We zouden kunnen de uitgangsspanning van de transformator verhogen door

die primair op de 220V aftakking aan te sluiten, wat leidt tot een 10% hogere

spanning op de sekundaire.

- 30.09.2019: Uitvoerige tests van de beater-module.

Velocity

scalings aangepast in de firmware. Meetgegevens opgenomen in de kommentaren

bij de bronkode voor de betreffende

microcontroller. De pulsduren zijn nu 7.5ms tot 40ms. De haalbare repetitiesnelheid

is beter dan wat we hadden verwacht, ondanks de grote massa van de ankers.

Uiteraard is die repetitiesnelheid groter naarmate de pulsduren korter worden

genomen. Boren van montagegaten in de 100x50 dwarsverstevigingsbalk. Hierop

moeten de PCB's van de noten 66 tot 91 samen met hun voeding gemonteerd kunnen

worden. Het boren moet het inlassen voorafgaan, want eens ingelast is boren

onmogelijk. Ontwerpen uitgetekend voor de bevestiging van de buisresonatoren.

Velocity

scalings aangepast in de firmware. Meetgegevens opgenomen in de kommentaren

bij de bronkode voor de betreffende

microcontroller. De pulsduren zijn nu 7.5ms tot 40ms. De haalbare repetitiesnelheid

is beter dan wat we hadden verwacht, ondanks de grote massa van de ankers.

Uiteraard is die repetitiesnelheid groter naarmate de pulsduren korter worden

genomen. Boren van montagegaten in de 100x50 dwarsverstevigingsbalk. Hierop

moeten de PCB's van de noten 66 tot 91 samen met hun voeding gemonteerd kunnen

worden. Het boren moet het inlassen voorafgaan, want eens ingelast is boren

onmogelijk. Ontwerpen uitgetekend voor de bevestiging van de buisresonatoren.

- 01.10.2019: Tubo verlaat voor het eerst de lastafel. Tussenbalk (100x50x2)

aangepunt en hier en daar gelast. Voor het rechtzetten waren wel twee takels

nodig. Demper unit terug gemonteerd. Bestelling 6 elektromagneten voor de

kloppers van de noten 66 tot 71 bij Distrelec. Zagen en stemmen van de PVC

resonatoren voor het laagste oktaaf. De laagste negen noten worden als gesloten

pijp resonatoren uitgevoerd (noten 48 tot en met 56). Vanaf 57 gaan we door

met open pijpen. Op deze wijze wordt de bouwhoogte niet hoger dan de lengte

van de buis voor de laagste noot. Bochten 90 graden aan de resonatoren vastgekleefd

met PVC lijm. Begin van de konstruktie van de verschuifbare afsluitkappen

voor de gesloten pijpen. Voor de laagste pijp kunnen we een inox potje gebruiken

dat heel precies de juiste binnenmaat, 60 mm, heeft. Herkomst onbekend. Ikea,

Casa, Blokker, Hema...?

- 02.10.2019: Beater eenheid op de hoofdstruktuur gemonteerd. Hiervoor zijn

twee mensen nodig!

Voedings

unit op de basis ingepast en vastgezet. Berekening en ontwerp van het resonatormechanisme.

Voor de aandrijving van het vibratomechanisme zouden we kunnen gebruik maken

van een Dunker motor met vertragingskast, voorzien van een excentrisch wiel.

Op voorraad hebben we een motor, type BG40x50, voedingsspanning 24V, 2.1A.

Daarop zit een 4:1 planetaire vertragingskast type PLG42S (90Ncm), waardoor

we een omloopsnelheid krijgen van 910 rpm. De maximale vibratofrekwentie wordt

dan 15Hz, wat hoe dan ook veel te snel is voor de totale massa die we hier

in beweging moeten krijgen.

Voedings

unit op de basis ingepast en vastgezet. Berekening en ontwerp van het resonatormechanisme.

Voor de aandrijving van het vibratomechanisme zouden we kunnen gebruik maken

van een Dunker motor met vertragingskast, voorzien van een excentrisch wiel.

Op voorraad hebben we een motor, type BG40x50, voedingsspanning 24V, 2.1A.

Daarop zit een 4:1 planetaire vertragingskast type PLG42S (90Ncm), waardoor

we een omloopsnelheid krijgen van 910 rpm. De maximale vibratofrekwentie wordt

dan 15Hz, wat hoe dan ook veel te snel is voor de totale massa die we hier

in beweging moeten krijgen.

- 03.10.2019: Konstruktie van de lange as voor het vibrato mechaniek: 12mm

gehard inox, lengte 1170mm. De vier draaipunten gemaakt in 10 mm dik aluminium

(50x100x10), aan de onderzijde voorzien van twee ingetapte M4 schroefdraden

voor de bevestiging aan de inox plaat waarop de resonatoren gemonteerd worden.

Montage van de resonatoren met 10 mm dikke afstandhouders in aluminium, gemonteerd

met twee M4 schroeven en ingetapte schroefdraden in de aluminium plaatjes

(100 x 40 x 10). Hier is een zicht op de nog onvolledig gemonteerde resonator

zijde:

We hebben

wel een probleem met torsie op de montageplaat van de resonatoren, waardoor

de meenemer niet gelijktijdig alle resonators doet bewegen.

We hebben

wel een probleem met torsie op de montageplaat van de resonatoren, waardoor

de meenemer niet gelijktijdig alle resonators doet bewegen.

- 04.10.2019: Experimenten rond het verhelpen van het torsieprobleem: versteviging

van de bevestigingslat of plaatsing van een tegengewicht? Konstruktie van

de ontbrekende hoedjes voor de gesloten pijp resonatoren op de laagste buizen.

Vastkleven van de bochten op de resonatoren voor de noten 60 tot 65 met PVC

lijm. We zijn bijna halfweg de konstruktie van de <Tubo> robot nu...

- 05.10.2019: Verder werk aan de versteviging van de resonatordrager: Aluminium

L-profiel (50x30x3) vastgemaakt op de 10 mm dikke asdragers in aluminium.

Hiertoe werden M4 schroefdraden in de asdragers getapt. Aan de kant van de

hoge noten moesten we het profiel wat taps laten uitlopen om kontakt met de

klankbuisdragers te vermijden. Voor het terugplaatsen van de as zijn weer

twee mensen nodig. Voor de beweging aangedreven met de motor moeten we nu